Gas turbine combustion chamber nozzle and method for premixing fuel and air in nozzle

A gas turbine and combustion chamber technology, which is applied to combustion methods, combustion chambers, continuous combustion chambers, etc., can solve the problems of insufficient number of fuel holes on rotating blades, high flame combustion temperature, and high NOx emission, and achieves improvement of thermoacoustic oscillation. Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

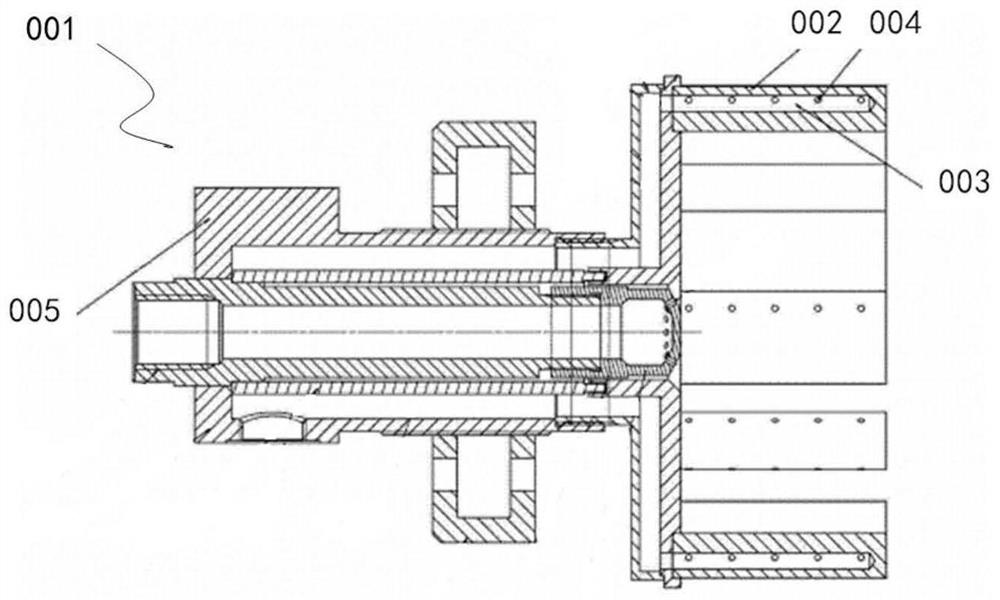

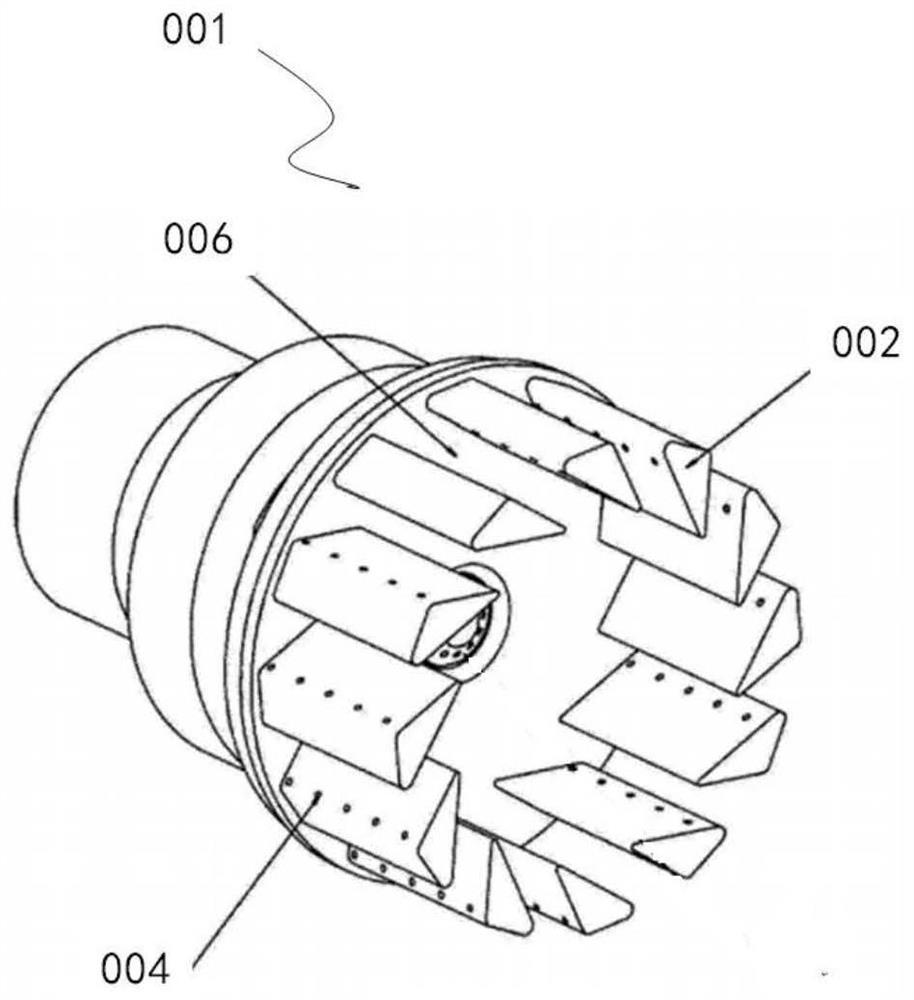

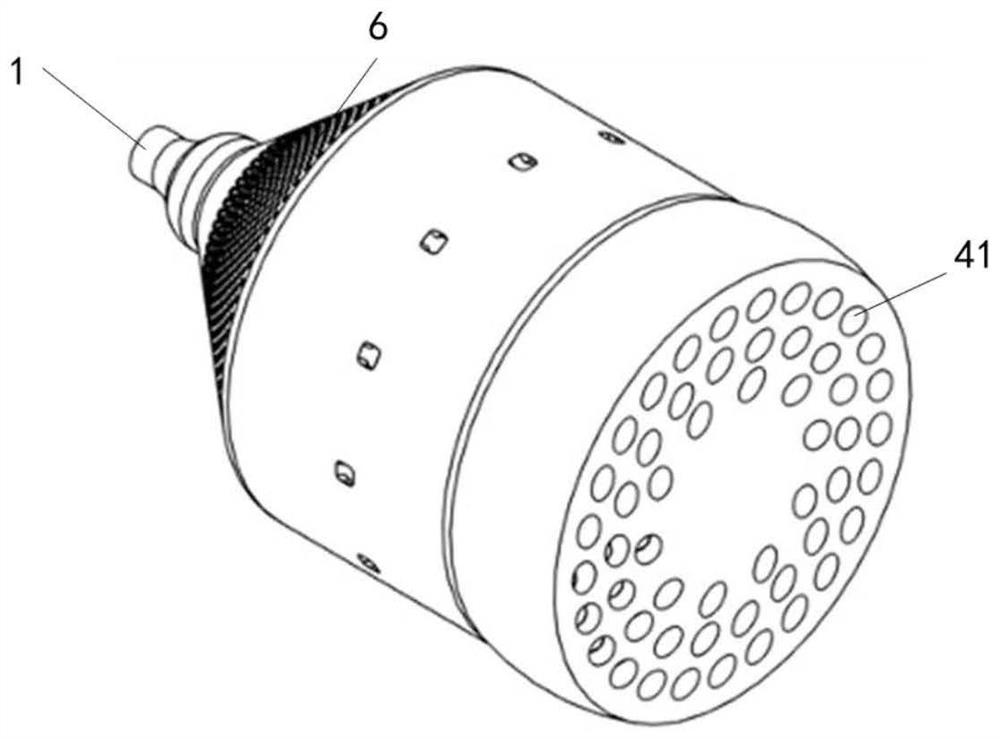

[0059] to combine Figure 3-4As shown, the gas turbine combustor nozzle includes a fuel delivery manifold 1 , a fuel distribution pipeline 2 , a fuel spray rod 3 and a fuel-air premixing pipe 4 . The fuel delivery main pipe 1 is in the shape of a spindle as a whole, the diameter of the fuel inlet gradually increases, and the outlet at the other end is conical, and several circular fuel distributing holes 5 are distributed on the conical shape.

[0060] In this embodiment, the fuel distributing holes 5 are uniformly distributed in the downstream outlet end of the fuel delivery main pipe 1 in a circular shape along the circumferential direction. Optionally, the fuel distributing holes 5 extend from the center of the nozzle 100 to The outside is arranged in multiple rows. After the fuel enters the system from the fuel delivery main pipe 1, it passes through the fuel distribution hole 5 on the downstream outlet of the fuel delivery main pipe 1 and then enters the fuel spray rod 3...

Embodiment 2

[0066] combine Figure 3-4 As shown, the gas turbine combustor nozzle includes a fuel delivery manifold 1 , a fuel distribution pipeline 2 , a fuel spray rod 3 and a fuel-air premixing pipe 4 . The fuel delivery main pipe 1 is in the shape of a spindle as a whole, the diameter of the fuel inlet gradually increases, and the outlet at the other end is conical, and several circular fuel distributing holes 5 are distributed on the conical shape.

[0067] In this embodiment, the fuel distributing holes 5 are uniformly distributed in the downstream outlet end of the fuel delivery main pipe 1 in a circular shape along the circumferential direction. Optionally, the fuel distributing holes 5 extend from the center of the nozzle 100 to The outside is arranged in multiple rows. After the fuel enters the system from the fuel delivery main pipe 1, it passes through the fuel distribution hole 5 on the downstream outlet of the fuel delivery main pipe 1 and then enters the fuel spray rod 3. ...

Embodiment 3

[0074] combine Figure 3-4 As shown, the gas turbine combustor nozzle includes a fuel delivery manifold 1 , a fuel distribution pipeline 2 , a fuel spray rod 3 and a fuel-air premixing pipe 4 . The fuel delivery main pipe 1 is in the shape of a spindle as a whole, the diameter of the fuel inlet gradually increases, and the outlet at the other end is conical, and several circular fuel distributing holes 5 are distributed on the conical shape.

[0075] In this embodiment, the fuel distributing holes 5 are uniformly distributed in the downstream outlet end of the fuel delivery main pipe 1 in a circular shape along the circumferential direction. Optionally, the fuel distributing holes 5 extend from the center of the nozzle 100 to The outside is arranged in multiple rows. After the fuel enters the system from the fuel delivery main pipe 1, it passes through the fuel distribution hole 5 on the downstream outlet of the fuel delivery main pipe 1 and then enters the fuel spray rod 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com