Data acquisition system of graphite carbonization system based on Internet of Things

A data acquisition system and data acquisition technology, applied in the direction of graphite, instruments, measuring devices, etc., can solve the problems of high heat consumption, high production cost, inconvenient control, etc., and achieve the effects of uniform heating, improved purity, and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

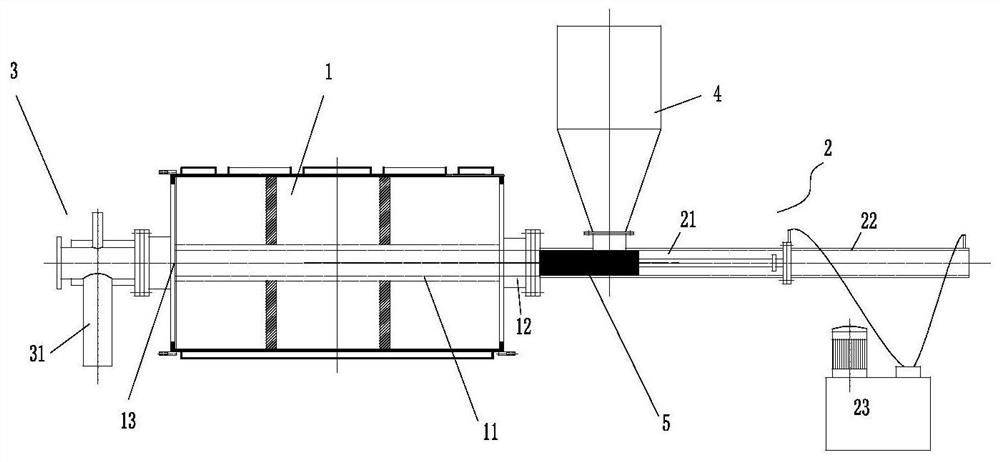

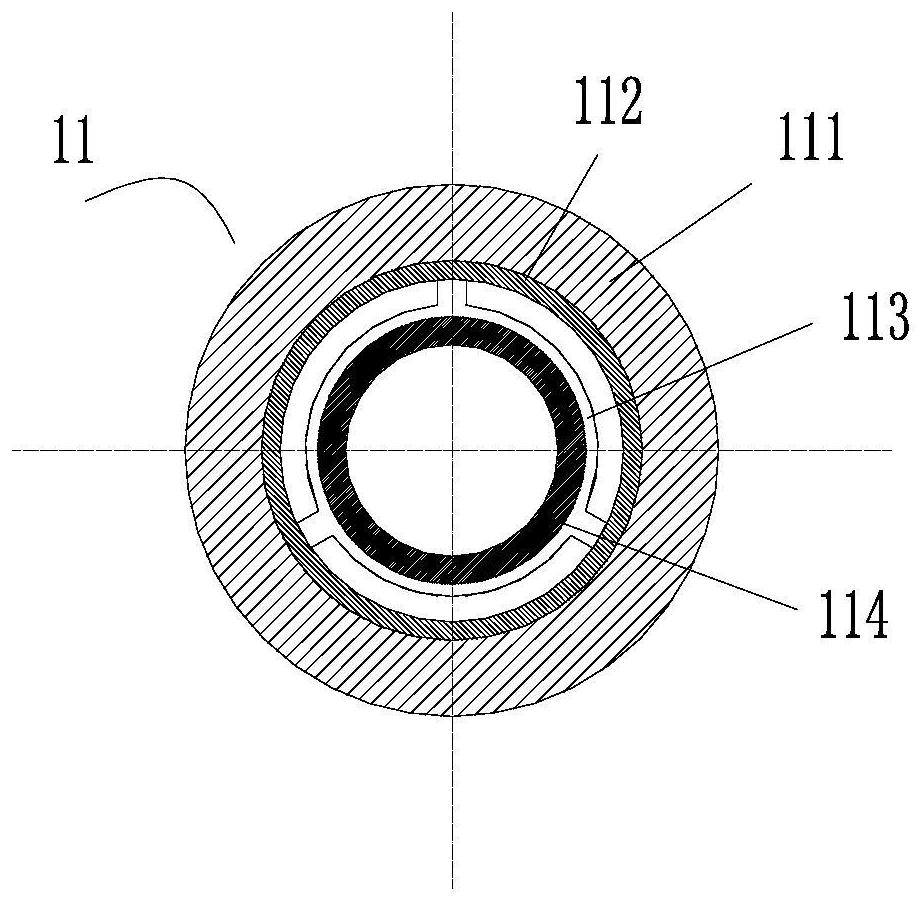

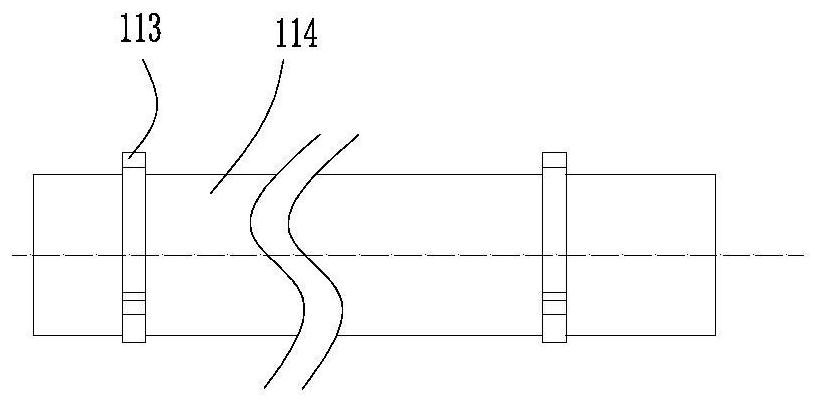

[0098] like Figure 5 , the data acquisition system is used for data acquisition of the graphite carbonization system; the graphite carbonization system includes a carbonization furnace; carbon tubes are arranged in the carbonization furnace; the data acquisition system includes an MCU and a data acquisition module; Detection module and finished product weight detection module; the finished product weight detection module is used to detect the weight of the existing finished product output from the discharge port; the temperature detection module is used to collect the temperature of the carbon tube and the temperature of the furnace body surface; the temperature detection module includes 3 groups of temperature detection mechanism; each group of temperature detection mechanism includes 4 temperature measuring probes, 4 infrared thermometers and 4 temperature sensors;

[0099] The installation method of each group of temperature detection mechanism is as follows:

[0100] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com