Sulfur-containing flue gas dust remover

A dust collector and flue gas technology, applied in chemical instruments and methods, fixed filter element filters, separation methods, etc., can solve the problems of judging dust collectors, inconvenient operation, inability to obtain real-time information, etc., to ensure detection accuracy and simplify. Structure, the effect of preventing a large amount of unqualified flue gas from being discharged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

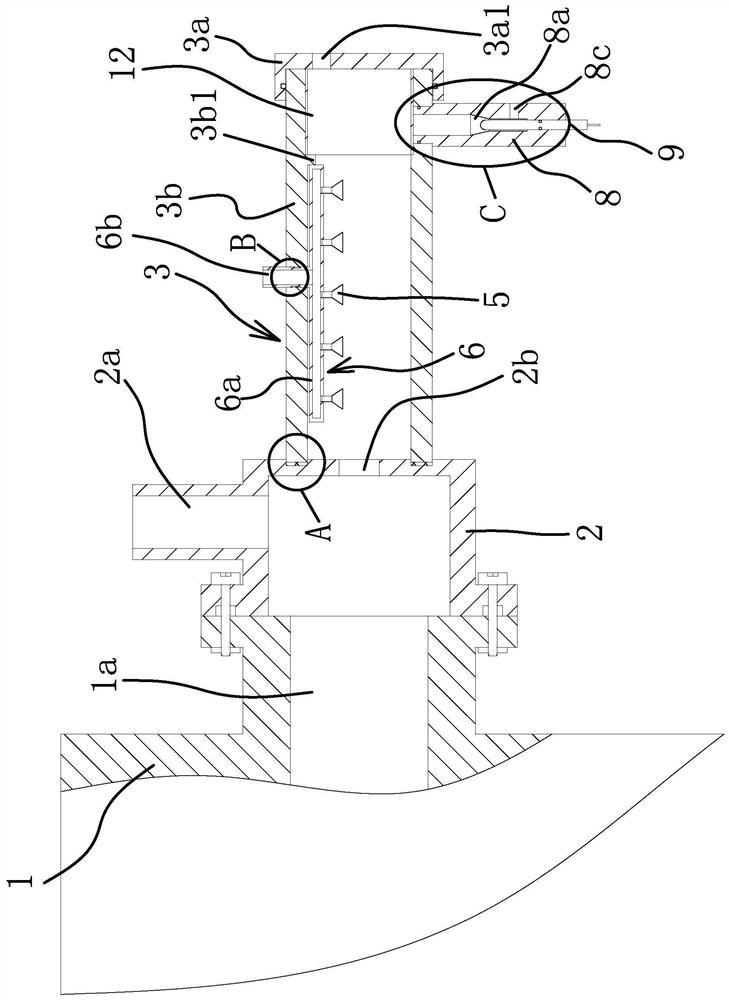

[0027] like figure 1 As shown, the sulfur-containing flue gas dust collector includes a pH meter and a dust collector body 1, wherein, the pH meter and the dust collector body 1 are existing products, and their structures are existing, and will not be described in detail here.

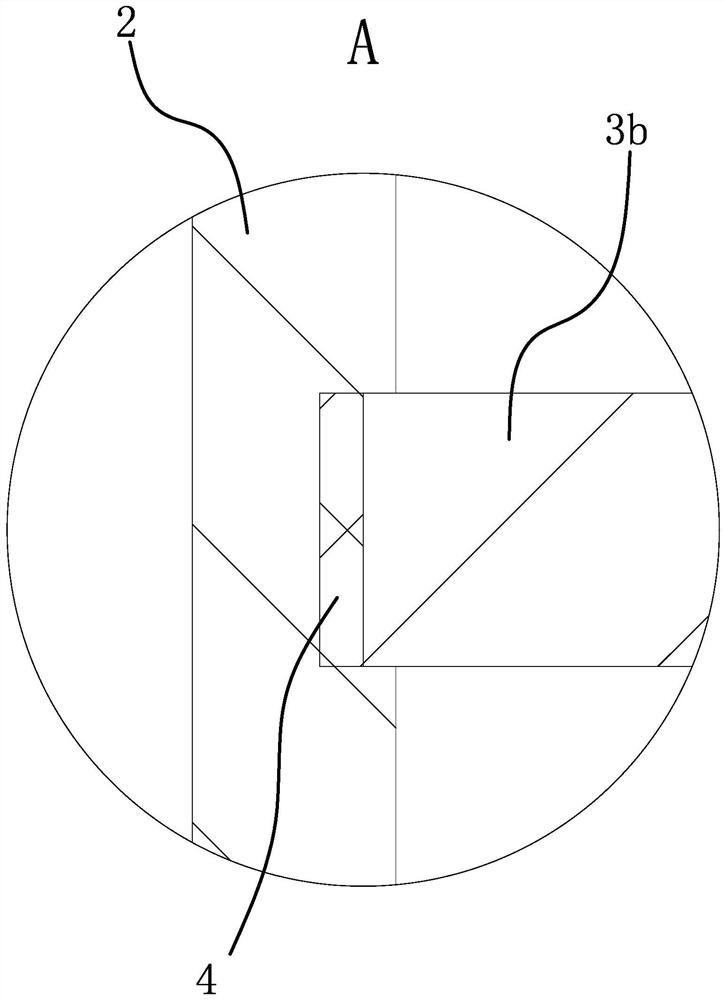

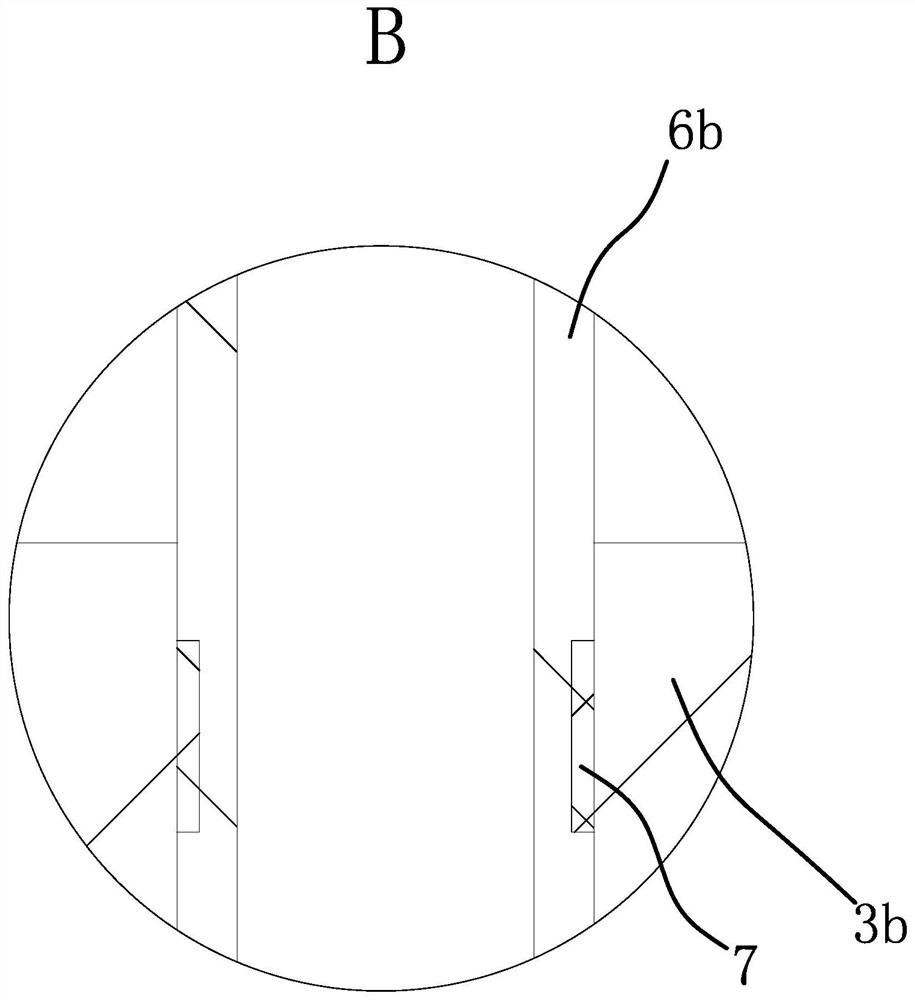

[0028] Specifically, the dust collector body 1 includes a smoke inlet and a smoke outlet 1a, and the smoke inlet and the smoke outlet 1a are respectively arranged on the lower side and the upper side of the dust collector body 1 . like figure 1 As shown, a gas collecting hood 2 is fixed on the right side of the dust collector body 1, and the inner cavity of the gas collecting hood 2 communicates with the exhaust port 1a. In this embodiment, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com