Connecting plate and solid oxide fuel cell/electrolytic cell stack

A solid oxide and fuel cell technology, used in fuel cells, circuits, electrical components, etc., can solve problems such as affecting the service life of the stack and destroying the structure of the single cell, and achieve the effect of reducing the difficulty of packaging and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

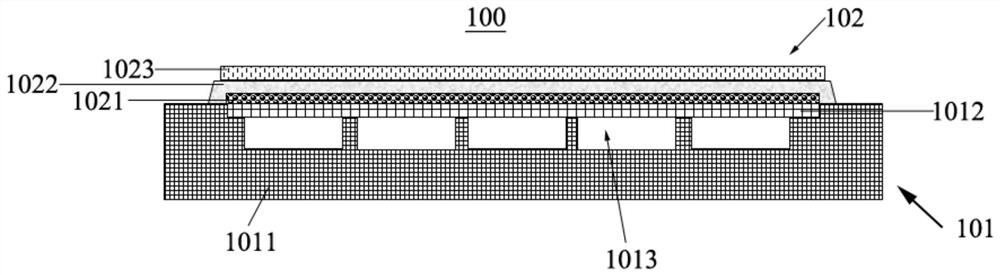

[0030] Since the solid oxide electrolytic cell and the fuel cell are a pair of energy conversion devices with the same structure and opposite working process, the specific implementation mode of this application is described by taking the solid oxide fuel cell as an example.

[0031] Generally, the operating voltage of a single solid oxide fuel cell can reach about 0.7V ~ 1.1V. Therefore, in order to improve electrical parameters such as output voltage and output power, it is usually necessary to integrate several, even dozens, or hundreds of The solid oxide fuel cells are connected together. Therefore, battery stack technology came into being.

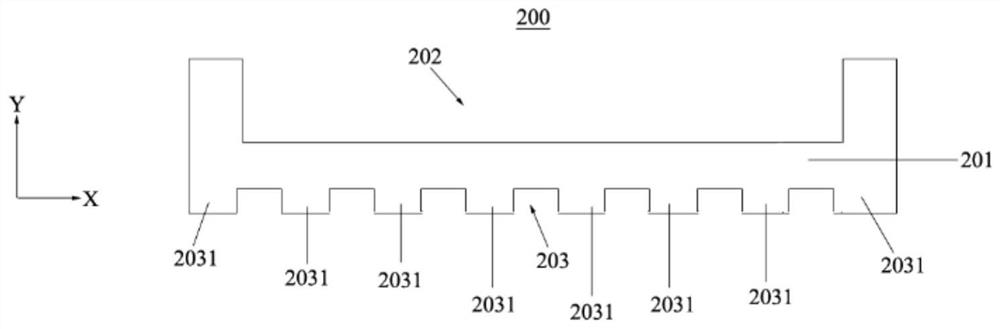

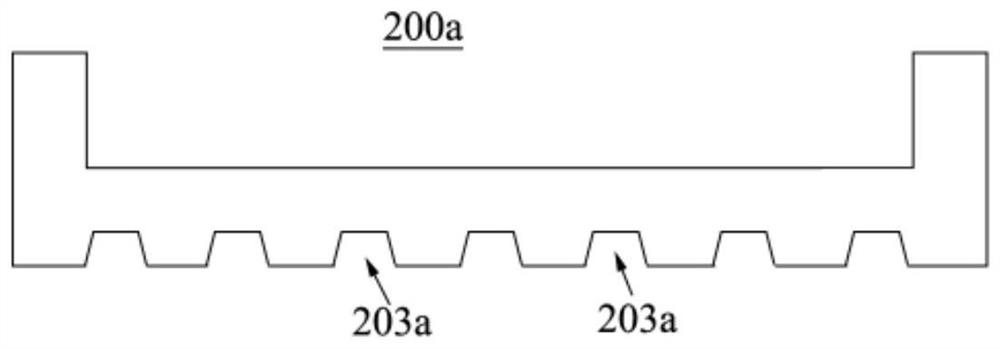

[0032] In view of some defects and difficulties in the existing battery stack technology—for example, its sealing process is complicated, the production cost is high, etc.—the inventor proposes a novel connecting plate 200 used in the battery stack after research; the connecting plate 200 structured as figure 2 shown.

[0033] Uti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com