Power distribution cabinet with heat dissipation function for automobile manufacturing factory

A technology for automobile manufacturing and power distribution cabinets, applied in substation/distribution device casings, electrical components, substation/switch layout details, etc. , difficult to extract moisture and other problems, to achieve the effect of ensuring service life, increasing residence time, and ensuring heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

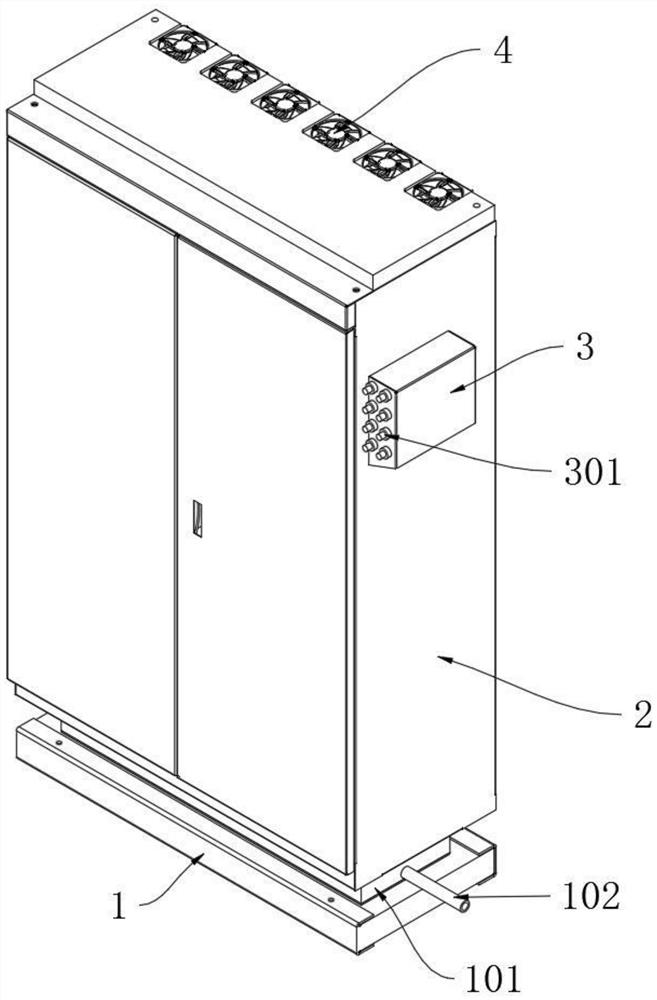

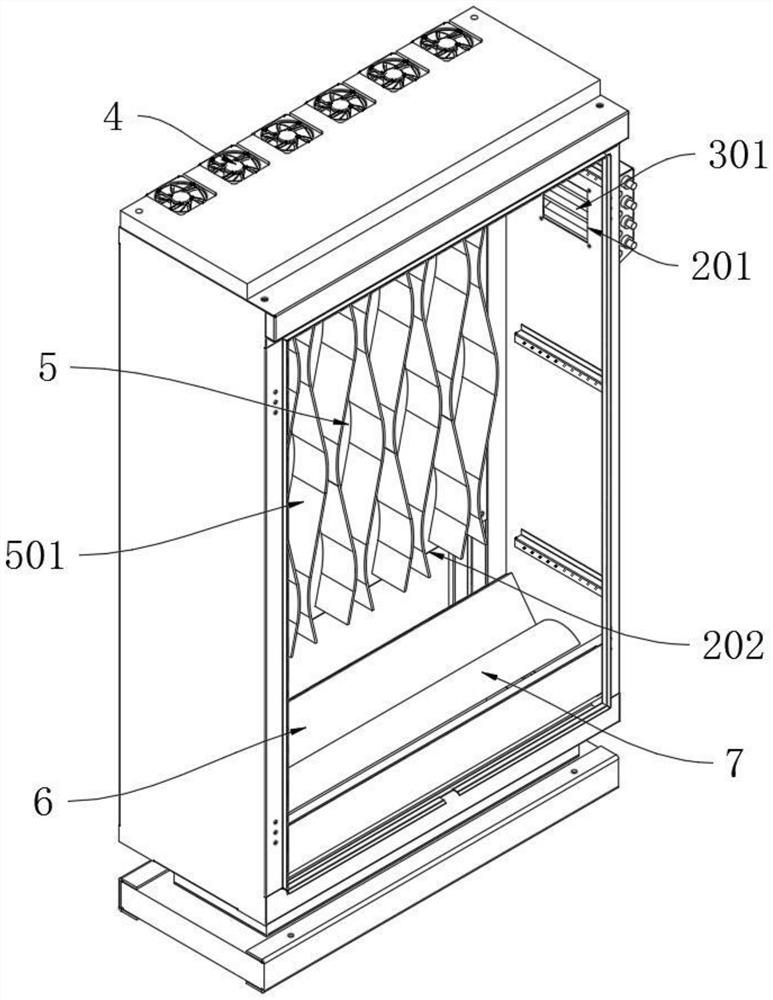

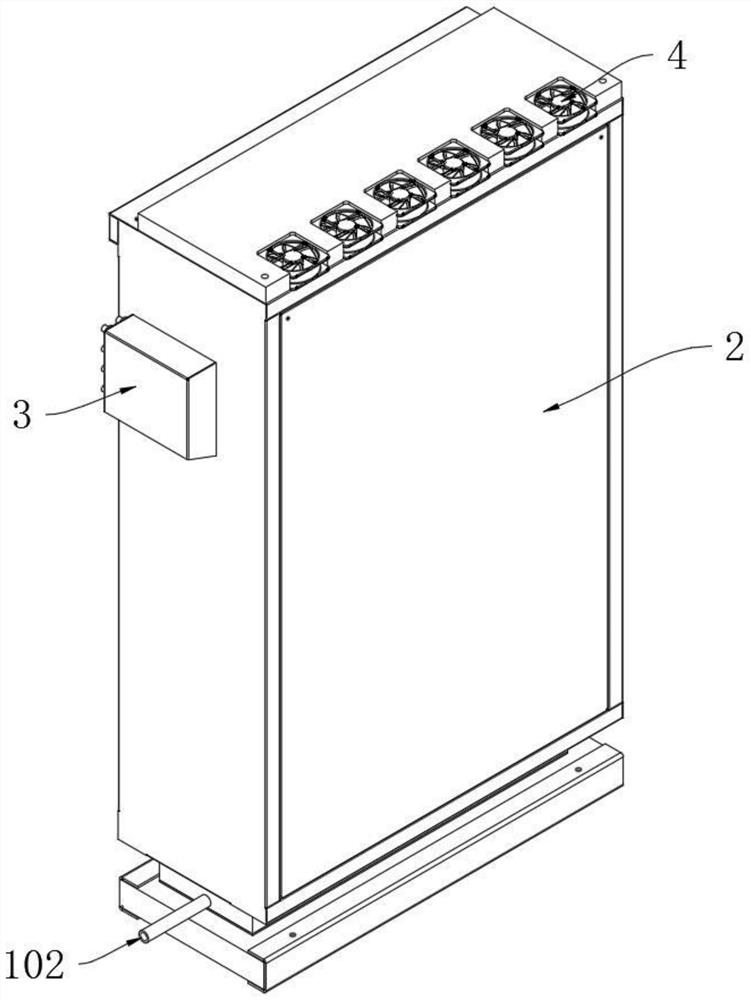

[0032] as attached figure 1 to attach Figure 6 Shown:

[0033] The invention provides a power distribution cabinet for automobile manufacturing plants with heat dissipation function, which includes a base 1, a cuboid power distribution cabinet main body 2 is fixedly installed on the upper end of the base 1, and the middle part of the right end side wall of the power distribution cabinet main body 2 is near the upper part The air intake filter box 3 is fixedly installed, and the inner end of the air intake filter box 3 is connected with the inner cavity of the main body 2 of the power distribution cabinet. There are 2-6 fixed and fixed installations at the rear edge of the top plane of the main body 2 of the power distribution cabinet. There are 6 cooling fans 4 arranged side by side in this embodiment. In the inner cavity of the main body 2 of the power distribution cabinet below the heat dissipation fan 4, a heat dissipation conversion backplane 5 is vertically fixedly ins...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap