Novel hexagonal handle gang drill

A new type of group drilling technology, which is applied in the direction of drill repair, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of difficult flow of cutting fluid, large speed difference, and affecting work efficiency, etc., to achieve good chip removal, The effect of increasing the feed rate and reducing the drilling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and examples, and the present invention is intended to be construed as limiting the scope of the invention.

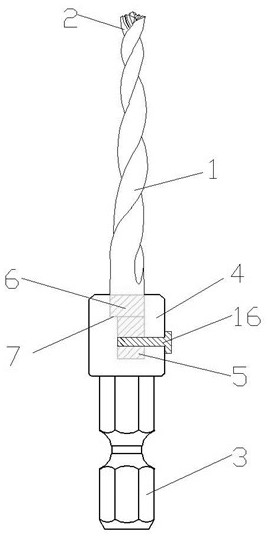

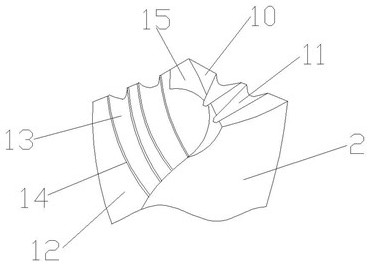

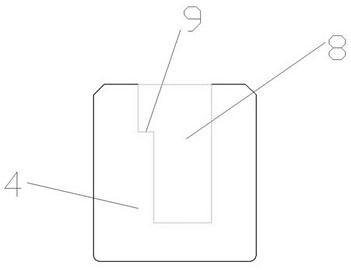

[0020] As shown, this embodiment provides a novel hexagonal group diamond, including hexagonal drill shank, twist-shaped drill pipe 1 and drill tip 2, and the diamond rod 1 has gradually thickened toward the drill tail. Thus strengthen the strength of the drill, it is not easy to break. The drill handle includes a hexagonal handle 3 and a kit 4 having a diameter greater than the diameter of the handle portion 3, and the end portion of the drill rod 1 is provided with a connection portion including a step. The insert 5 and the engaging portion 6, wherein the insert portion 5 is smaller than the diameter of the engaging portion 6, and is flush, so that the insert 5 and the engaging portion 6 form a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com