Machining system and machining method for spot facing

A processing system and surface facing technology, applied in metal processing equipment, manufacturing tools, components of boring machines/drilling machines, etc., can solve the problems of shape and position tolerance and surface roughness out of tolerance, large machining dimensional tolerance, etc., to achieve accurate depth of cut The effect of dimensional limit, high dimensional accuracy, and smooth and correct cutting state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

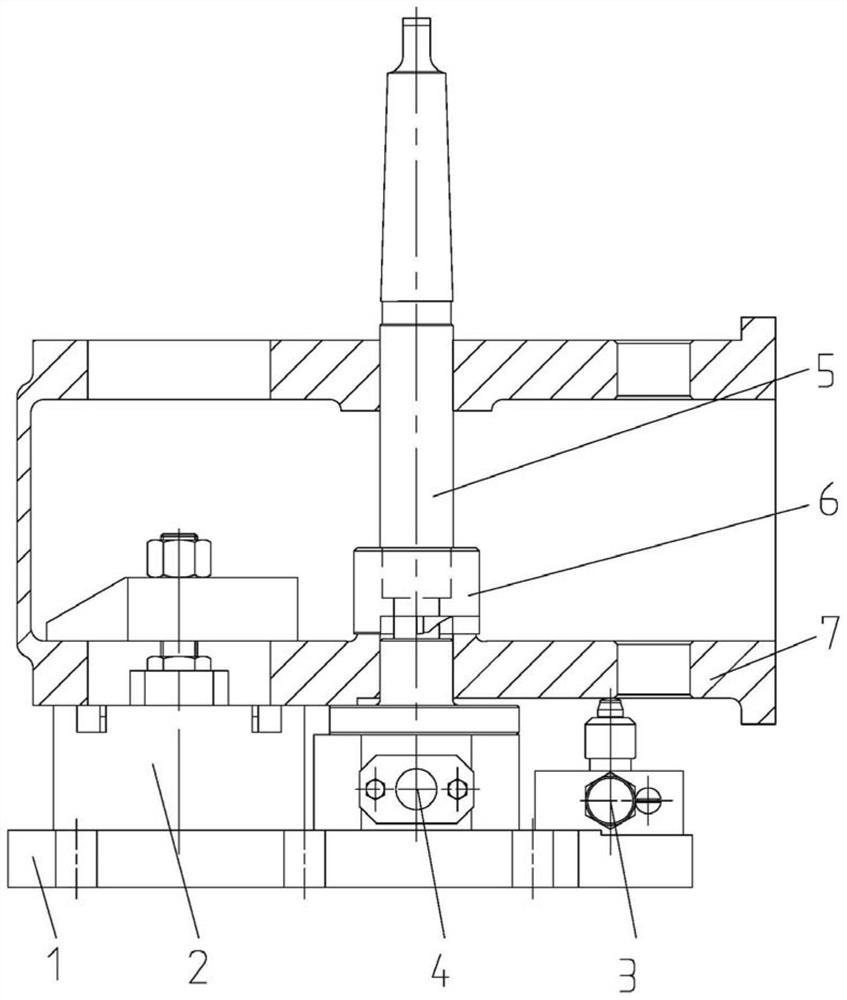

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

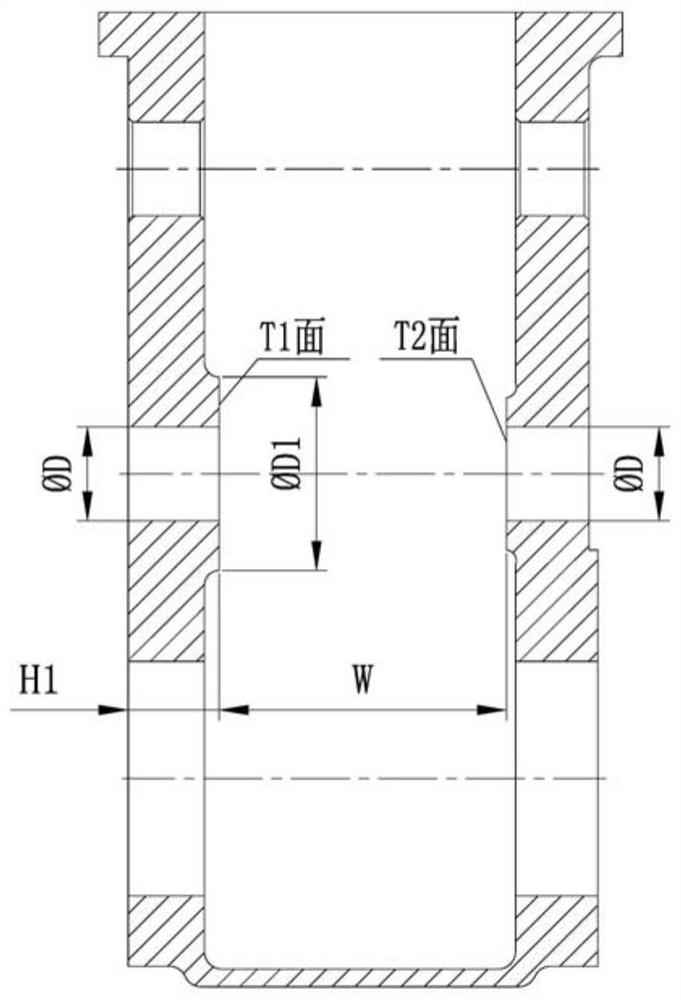

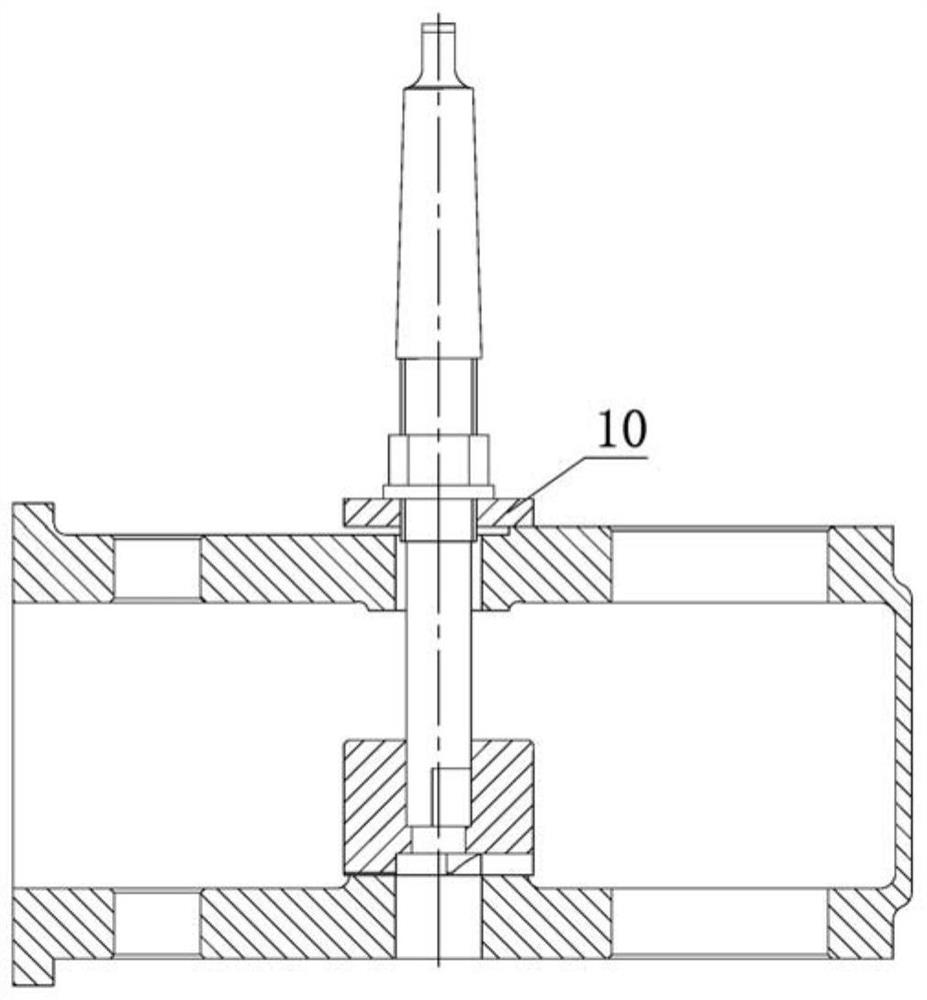

[0036] The invention provides a processing system and processing method for countersinking. The system also associates tools, fixtures and workpieces in the cutting process, so that the tools can respectively establish a cooperative relationship with the fixtures and workpieces, and realize a stable and correct cutting state and accurate cutting. The cutting depth size limit makes the dimensional accuracy after processing higher, so that the product quality of the spot facing inner cavity plane process is completely qualified and meets the design requirements.

[0037] Such as image 3As shown, the processing system for spot facing of the present invention includes a clamp unit and a tool unit; the clamp unit includes a clamp base plate 1, a positioning and pressing assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com