Seat cover based on heterogeneous material 3D printing technology and forming method thereof

A technology of 3D printing and heterogeneous materials, which is applied in the direction of seat covers, vehicle seats, 3D object support structures, etc., can solve the problems of complex process, time-consuming and labor-consuming product stability, etc., and achieve simple production process and save sewing Effect of reduction in time and number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

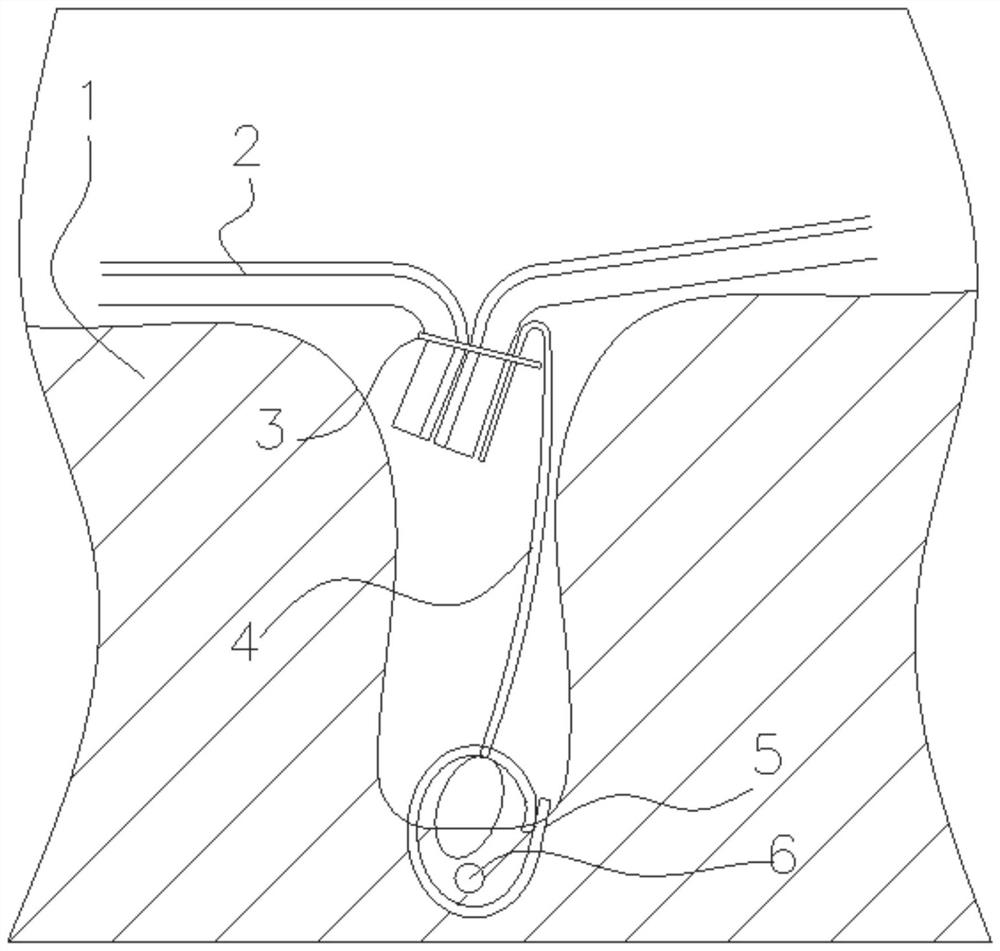

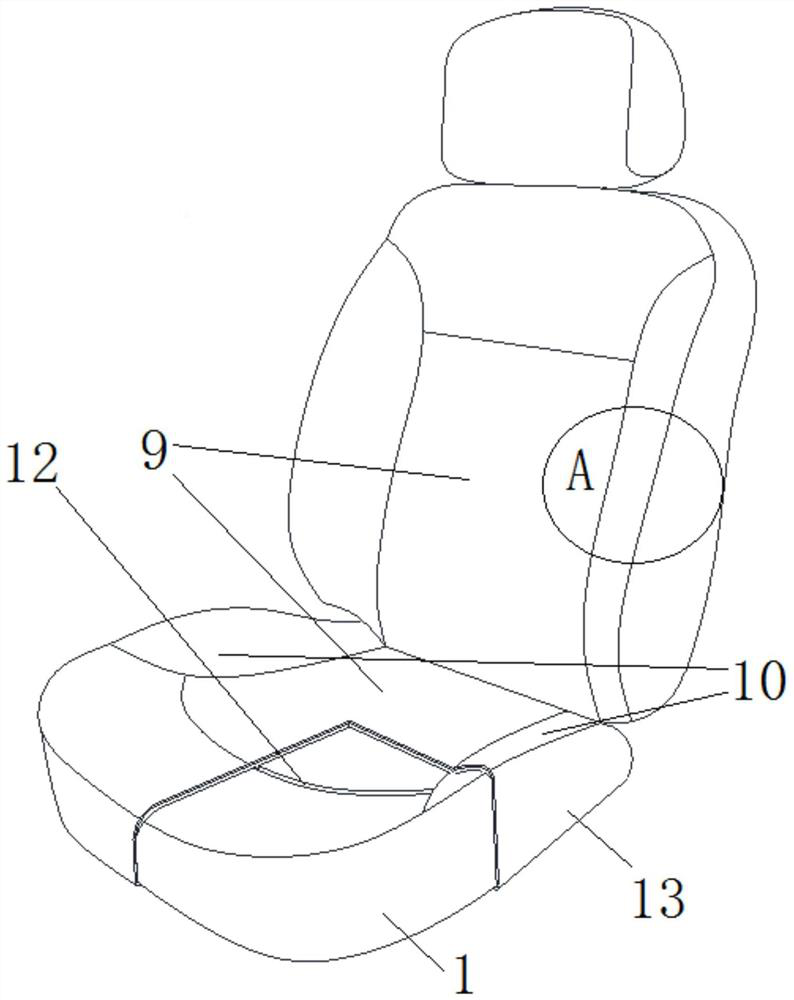

[0045] A seat cover based on heterogeneous material 3D printing technology, such as figure 2 As shown, it includes a middle piece 9, a side wing piece 10 and a skirt side piece 13, and the two side wings and the two skirt side pieces are arranged symmetrically on both sides of the middle piece;

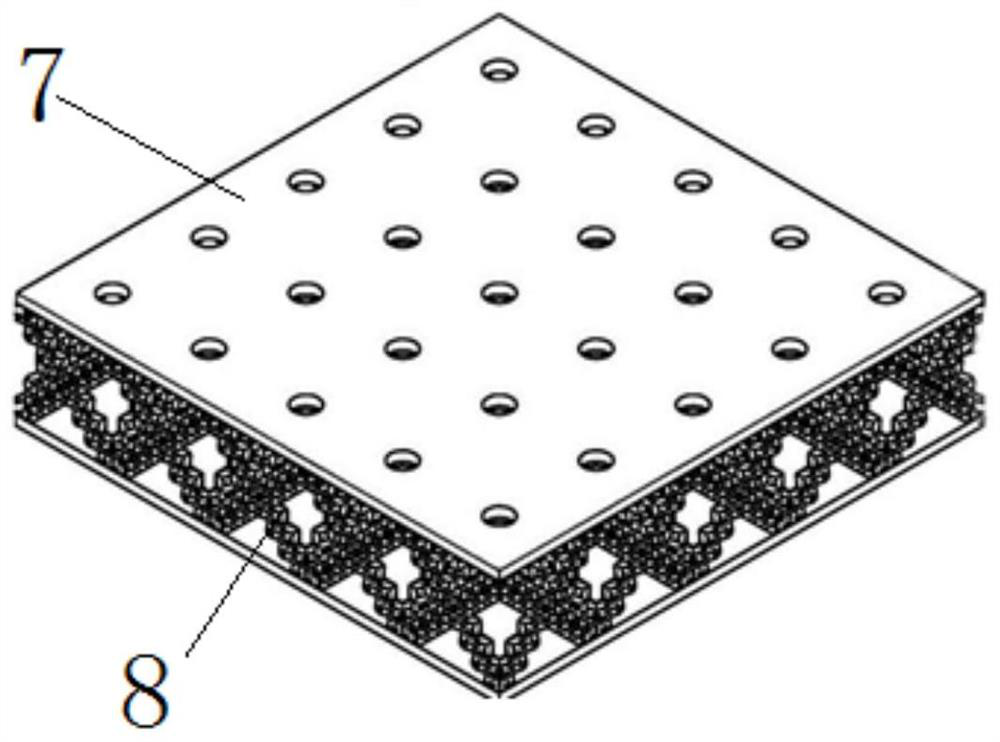

[0046] Intermediate film 9 as image 3 Shown is a mesh structure comprising a middle sheet surface layer 7 and a middle sheet support layer 8 which is in foamed contact with the seat;

[0047] The material of the support layer of the intermediate sheet is acrylated epoxy resin, unsaturated polyester, polyurethane or polythiol / polyene photocurable resin, the material of the surface layer of the intermediate sheet is rubber, the thickness of the intermediate sheet is 10mm, and the surface layer of the intermediate sheet is The thickness is 1-3mm, and the thickness of the support layer of the middle sheet is 7-9mm;

[0048] The side wing includes a side wing surface layer and a side w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com