A batch steel plate flip device system

A technology of flipping device and steel plate, which is applied in transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of cumbersome operation, long time, and large steel plate area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

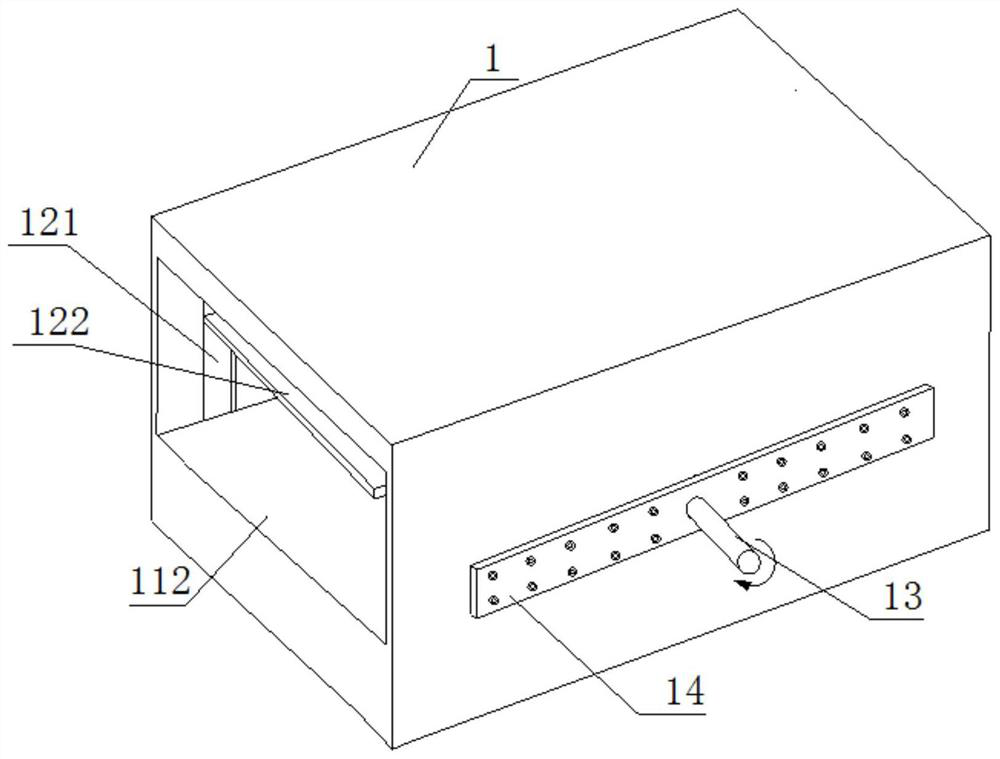

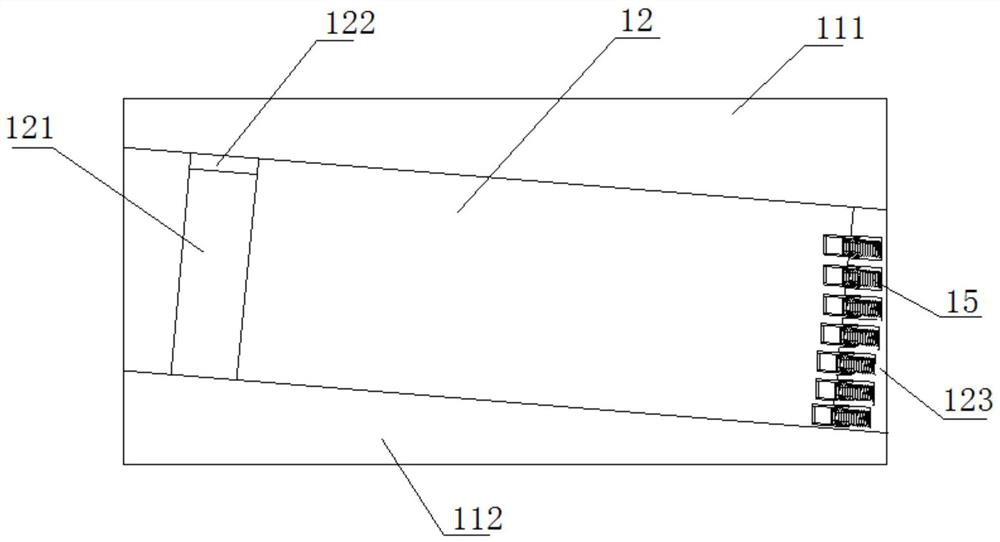

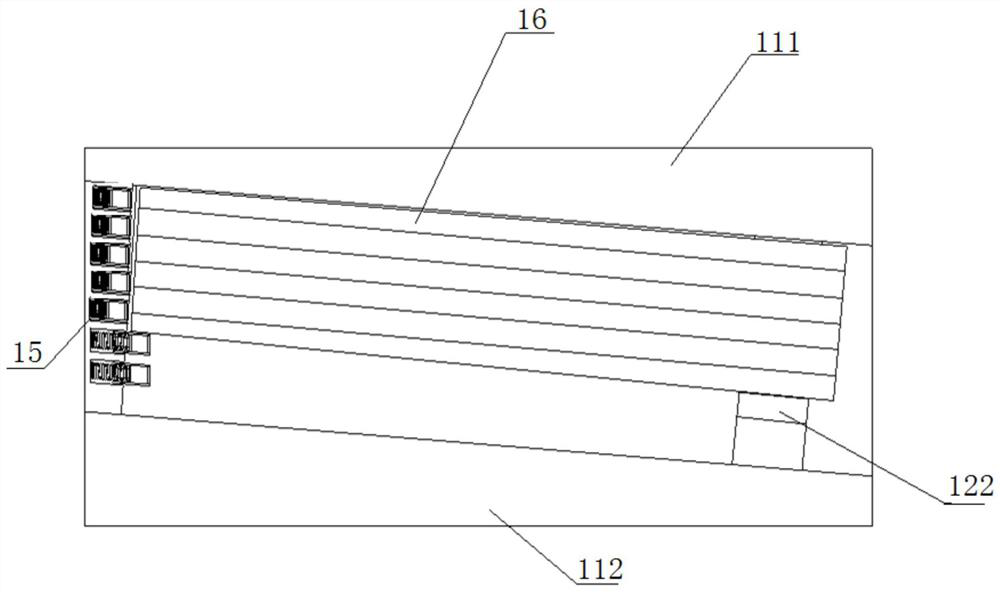

[0024] join Figure 1 to Figure 4 , the overall shape of the overturning device body 1 has a rectangular parallelepiped structure, and there is a accommodating cavity 12 extending through the overturning device body 1 , the accommodating cavity 12 is a parallelogram cavity, and the accommodating cavity 12 is a parallelogram cavity. The height is a multiple of the thickness of the steel plate 16, the width of the accommodating cavity 12 is slightly larger than the width of the steel plate 16, the inlet end of the accommodating cavity 12 is higher than the outlet end thereof, and the outlet end of the accommodating cavity 12 is provided with a limit plate 123, the inner surface of the limiting plate 123 is perpendicular to the top, bottom and side walls of the accommodating cavity 12, the limiting plate 123 may not completely cover the outlet end of the accommodating cavity 12, so as to facilitate stacking After the steel plate 16 is turned over, the pushing device extends into ...

Embodiment 2

[0026] like Figure 1 to Figure 4As shown, Embodiment 2 is based on Embodiment 1. The center of both sides of the turning device body 1 is provided with a rotating shaft 13, the rotating shafts 13 rotate synchronously and in the same direction, and the performance of the rotating shaft 13 is sufficient to support the turning device body. 1 rotation; a booster plate 14 is provided between the rotating shaft 13 and the outer surface of the turning device body 1, and the booster plate 14 and the rotating shaft 13 are integrally formed in a structure to increase its strength, and the booster plate 14 passes through A plurality of fasteners are fixed to the body 1 of the overturning device; a chute 121 is opened inside the accommodating cavity 12 , the length direction of the chute 121 is perpendicular to the bottom surface of the accommodating cavity 12 , and the height of the chute 121 is greater than The height of the accommodating cavity 12, the lifting plate 122 can cooperate ...

Embodiment 3

[0030] like Figure 5 As shown, Embodiment 3 is based on Embodiment 1, and the structure of the inversion device body 1 can also adopt another implementation manner, the difference is that the inversion device body 1 is divided into two oppositely arranged parts, and the two parts It can be a single structure or can be connected by a connecting plate or a connecting plate, as long as the two parts can rotate in the same direction and synchronously; the body 1 of the overturning device is also provided with an accommodating cavity 12, and the accommodating cavity 12 is two parts. The relative areas between the parts are combined, and both the top surface and the bottom surface of the accommodating cavity 12 can play a role in receiving the pallets; another embodiment is: the accommodating cavity 12 on both sides of the The side is provided with a frame structure such as a stop bar, which can also achieve a lateral restraint effect on the stacking steel plates 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com