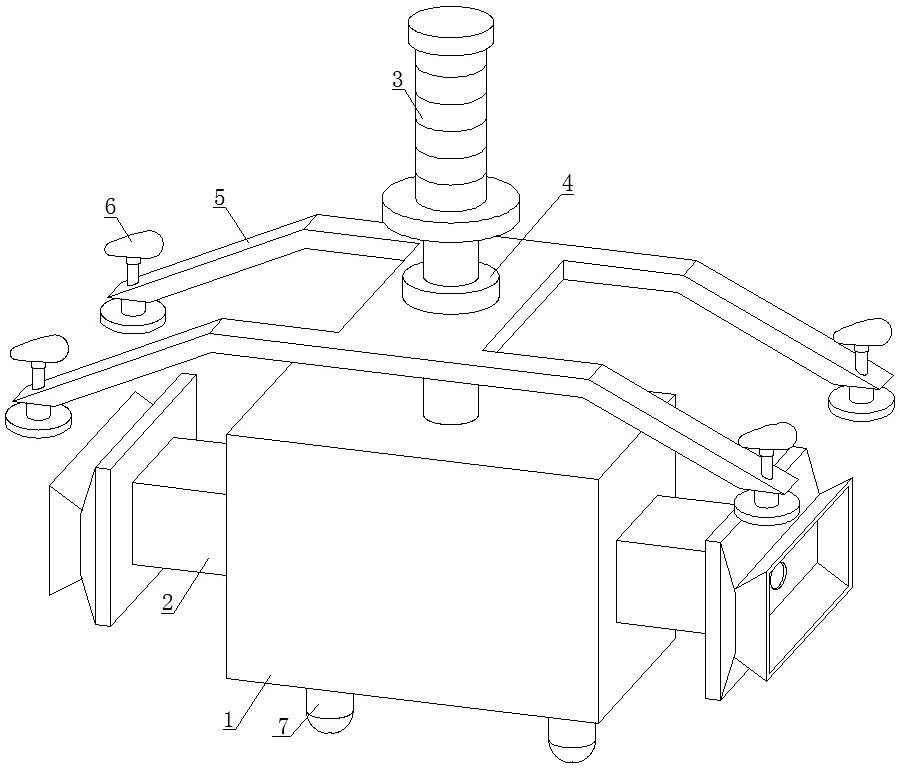

Reverse supporting device for bridge gap repairing and implementation method thereof

A reverse support and gap technology, applied in bridge repair, bridge, bridge reinforcement, etc., can solve the problems affecting the repair effect, automatic telescopic adjustment, dust and other sundries cannot be cleaned, etc., to achieve good wind resistance effect, The effect of improving the effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , 1 Embodiment approach

[0038] In order to further better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing a back support device for bridge gap repair, comprising the following steps:

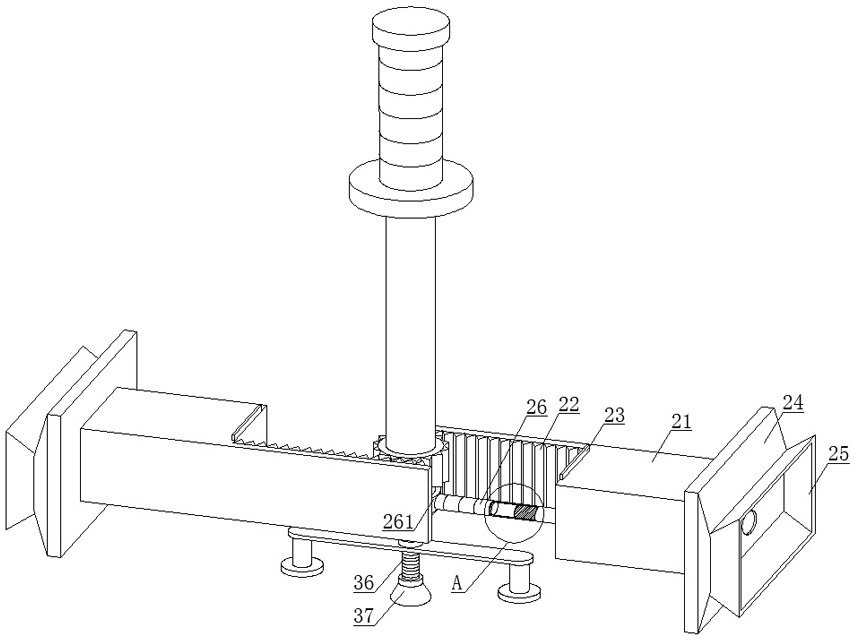

[0039] Step 1: The operator places the supporting shell 1 in the gap of the bridge, and adsorbs the suction cup B65 on both ends of the gap of the bridge;

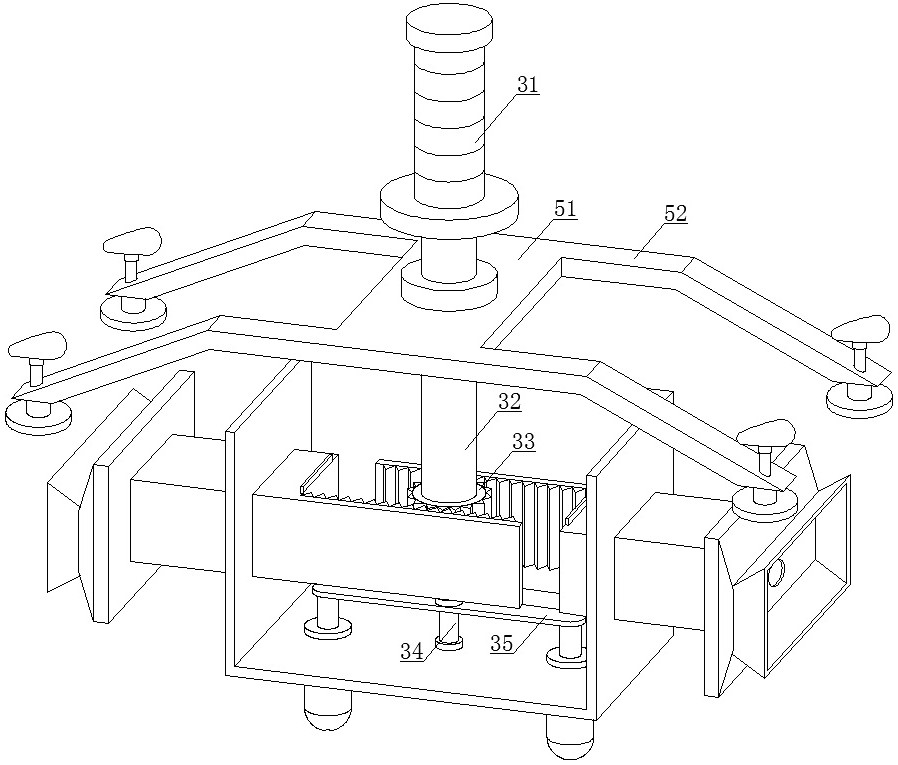

[0040] Step 2: Rotate the handle part 31 to rotate the gear 33, and the suction cups A25 at both ends of the two sets of supporting mechanisms 2 move to the inner wall of the gap and adsorb to the inner wall;

[0041] Step 3: Continue to rotate the handle part 31, and the threaded sleeve 351 drives the cross bar 352 to move downward until the hemisphere 72 touches the bottom of the gap;

[0042] Step 4: Press the handle portion 31 downward, the spring 311 contracts, the piston A314 moves downward, the internal gas drives the fan blade 38 to rotate, and then stops working.

[0043] In summary: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com