Engine minimum ignition density calculation method, engine control method and engine

A calculation method and engine technology, which is applied in engine control, machine/engine, electrical control, etc., can solve problems such as difficulty in judging platform surge, increase in pressure ratio, and decrease in flow rate, so as to reduce development costs and calibration costs, The effect of saving bench resources and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only the parts related to the present invention are shown in the drawings but not all of them.

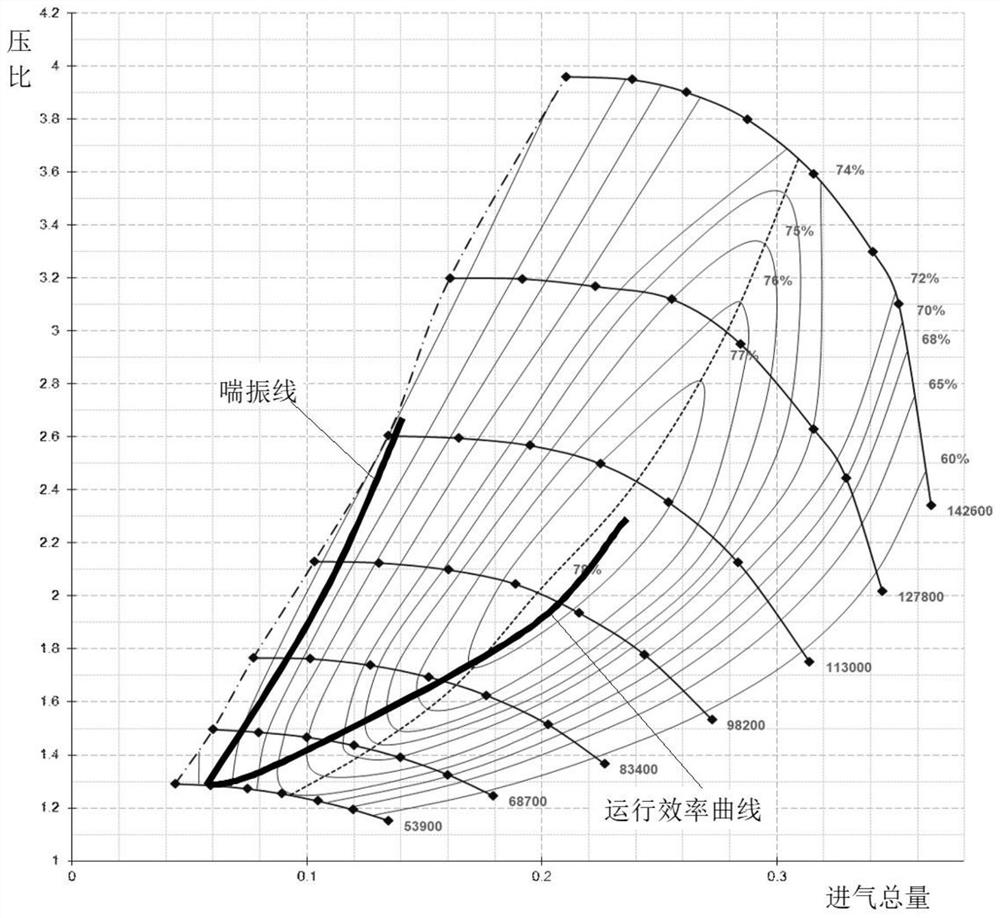

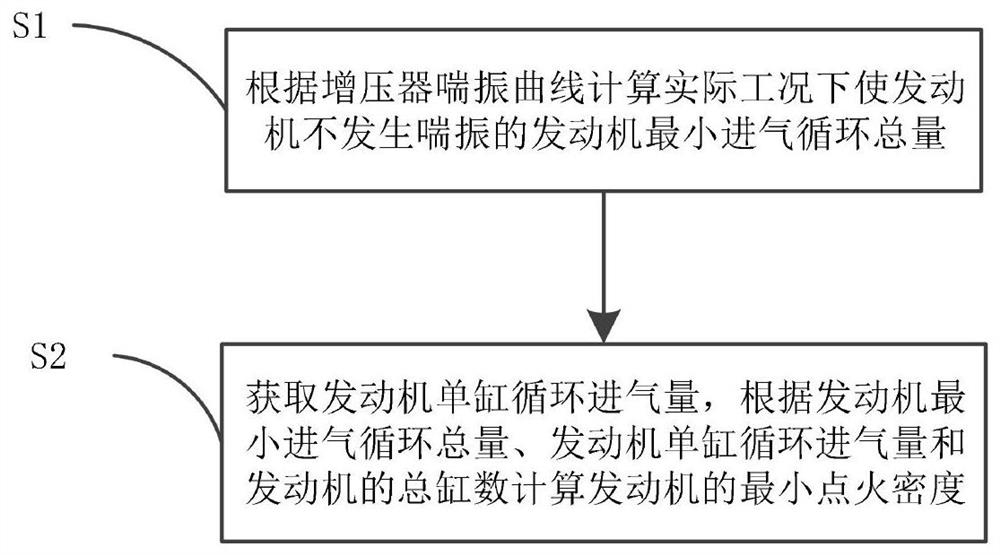

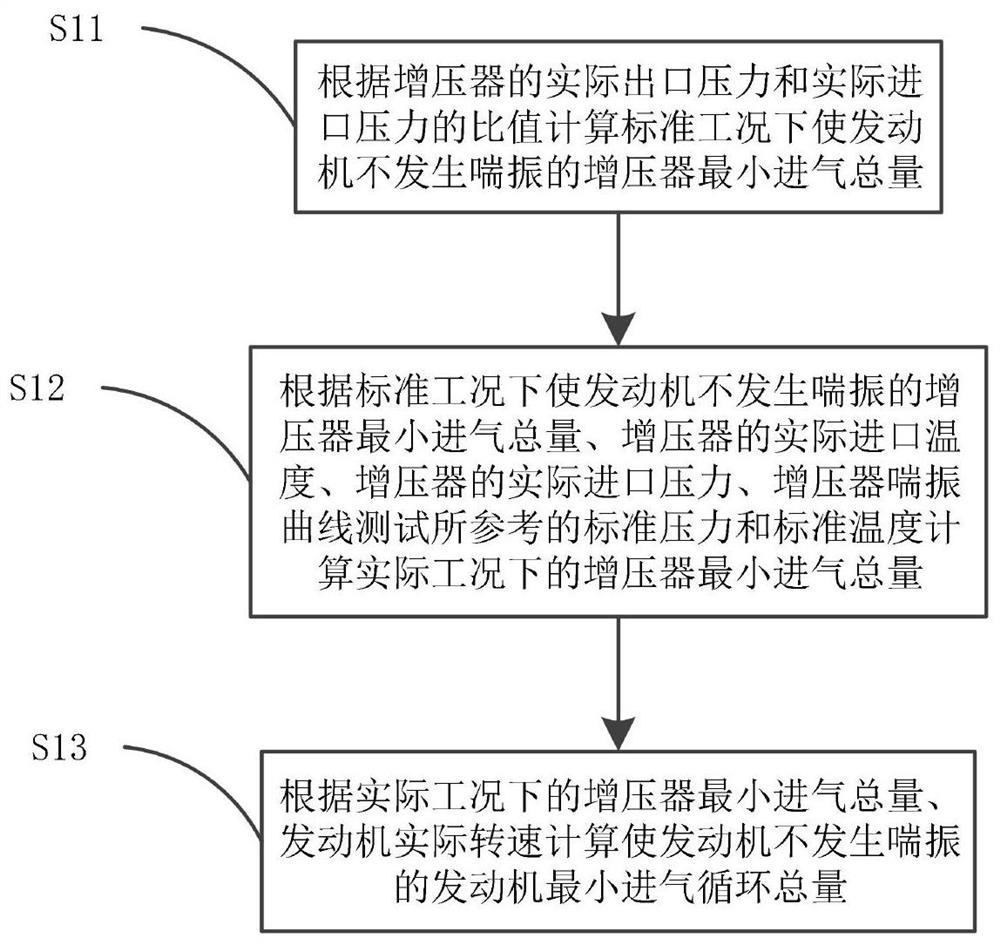

[0062] figure 1 is the characteristic curve of the pressure ratio of the supercharger - the total amount of intake air, where the pressure ratio represents the ratio of the inlet pressure to the outlet pressure of the supercharger, and the function expression of the supercharger operating efficiency curve is Among them, N 增压器转速 In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com