Pneumatic safety type pneumatic screw pump and using method thereof

A kind of screw pump, safe technology, applied in the direction of rotary piston type/oscillating piston type pump components, rotary piston type/oscillating piston type pump combination, pump, etc. Tight, inconvenient to adjust the flow rate of the liquid inlet pipe, etc., to reduce noise, reduce vibration, and prevent falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

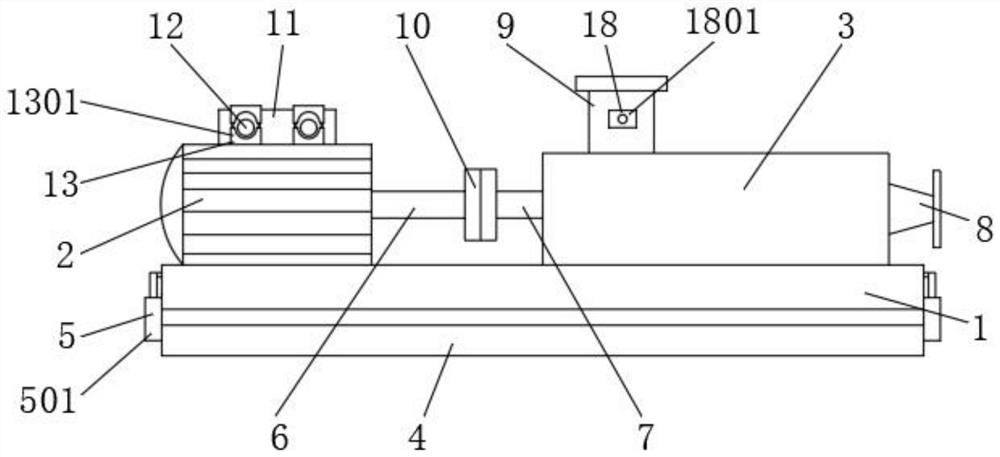

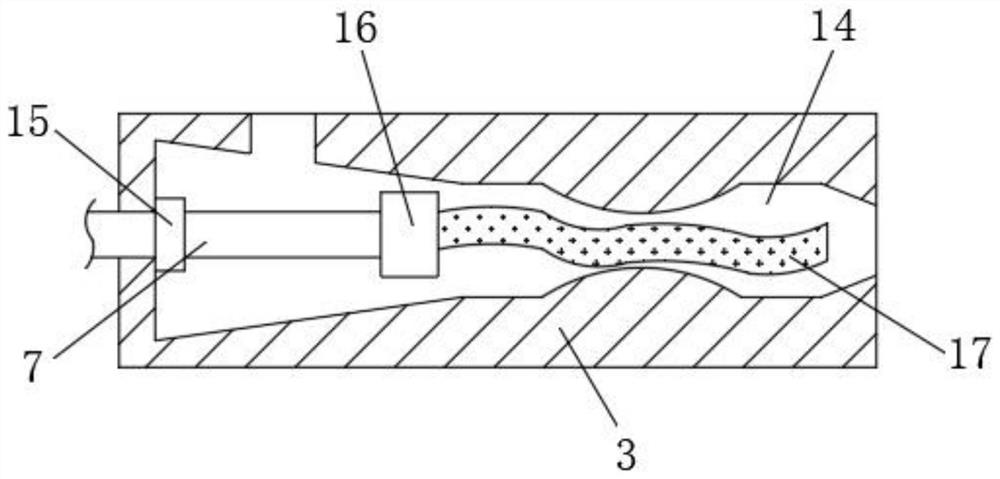

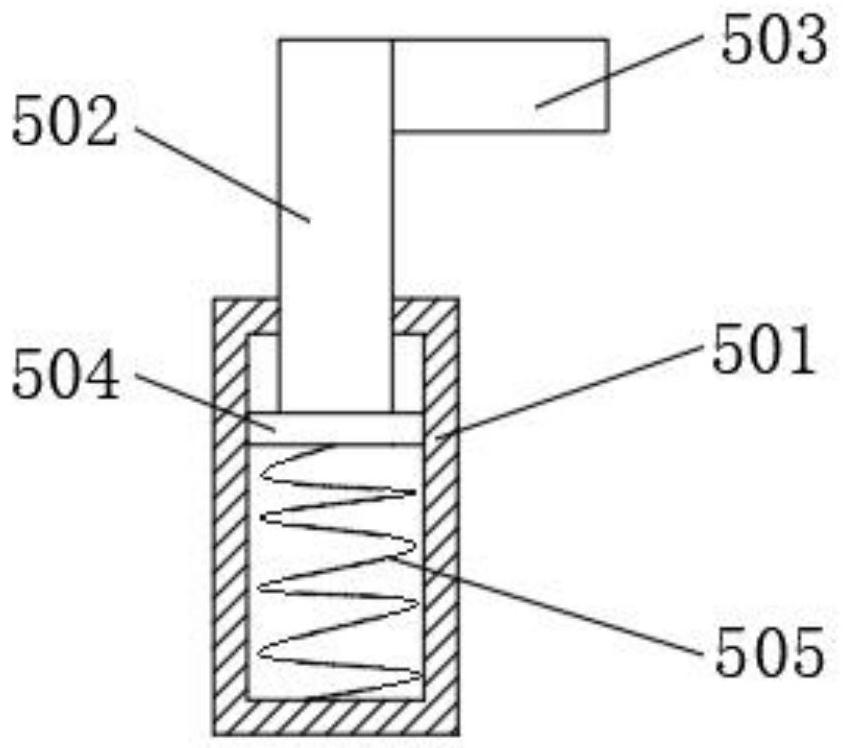

[0030] Such as Figure 1-5 As shown, the present invention relates to a pneumatically safe pneumatic screw pump, including a support base 1, an air motor 2 is fixedly installed on the upper surface of the support base 1 close to one side, and the upper surface of the support base 1 is fixed close to the other side The pump body casing 3 is installed, the base 4 is arranged under the support base 1, the shock absorbing mechanism 5 is connected between the base 4 and the support base 1, the output end of the air motor 2 is connected to a transmission shaft 6, and the pump body casing 3 One end is connected with the second transmission shaft 7, and the other end of the pump casing 3 is connected with a liquid outlet pipe 8, and the top of the pump casing 3 is connected with a liquid inlet pipe 9, between the first transmission shaft 6 and the second transmission shaft 7 A coupling 10 is connected, and the top of the air motor 2 is fixedly installed with an air connection seat 11,...

Embodiment 2

[0039] On the basis of Embodiment 1, a method for using a pneumatically safe pneumatic screw pump comprises the following steps:

[0040] S1: Connect the air pipe joint 12 to the air pipe, and connect the liquid inlet pipe 9 and the liquid outlet pipe 8 to the infusion pipe respectively;

[0041] S2: Pass the air pipe through the No. 1 tightening block 1301 and the No. 2 tightening block 1302 to connect with the air seat 11. The No. 2 tightening block 1302 is relatively movable through the connecting column 1303, the anti-drop joint 1304 and the return spring 1305. The air pipe is clamped;

[0042] S3: The air motor 2 starts to work, the air motor 2 drives the No. 1 transmission shaft 6 to rotate, the No. 1 transmission shaft 6 rotates through the coupling 10 to drive the No. 2 transmission shaft 7 to rotate, and the No. 2 transmission shaft 7 rotates through the universal joint 16 The feeding screw 17 is driven to rotate, and the feed liquid is delivered to the feeding chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com