Load-sensitive vane pump variable mechanism and displacement detection method thereof

A variable mechanism and load-sensitive technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of power, matching, and displacement detection without displacement sensor, etc., to achieve displacement detection and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

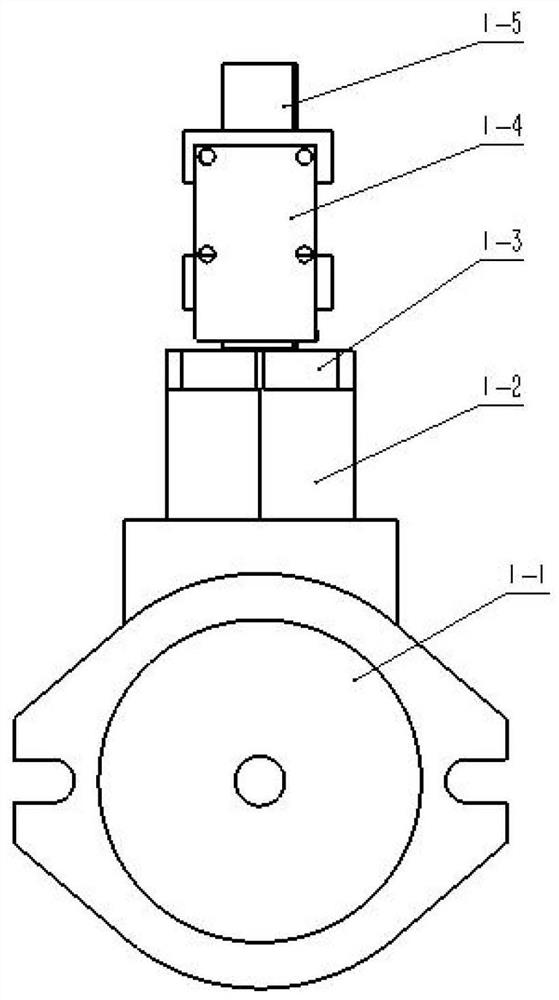

[0028] like figure 1 Shown is a load-sensitive vane pump variable mechanism and its displacement detection method, including: 1-1 vane pump, 1-2 variable mechanism, 1-3, variable mechanism end cover, 1-4, displacement sensor bracket, 1-5. Displacement sensor.

[0029] like figure 1 As shown, the variable ejector rod 5-2 presses against the stator of the vane pump to make the vane pump work at the maximum position. A spring is installed on the variable ejector rod 5-1, and the preload of the spring realizes the maximum displacement when the vane pump is started.

[0030] The variable ejector rod 5-1 is connected with the displacement sensor 1-4, because the variable ejector rod 5-2 is in contact with the stator all the time, so measuring the position of the variable ejector rod 5-1 is equal to measuring the displacement of the vane pump.

[0031]4-2 is the installation bracket of displacement sensor, and the hole of 4-2 and the hole of variable mechanism end cover 1-4 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com