Inclined Roots Screw Compound Vacuum Pump

A Roots screw and vacuum pump technology, applied in the direction of rotary piston pumps, pumps, rotary piston/swing piston pump components, etc., can solve problems such as high work efficiency, inability to meet precise positioning, and low reliability of vacuum pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the examples.

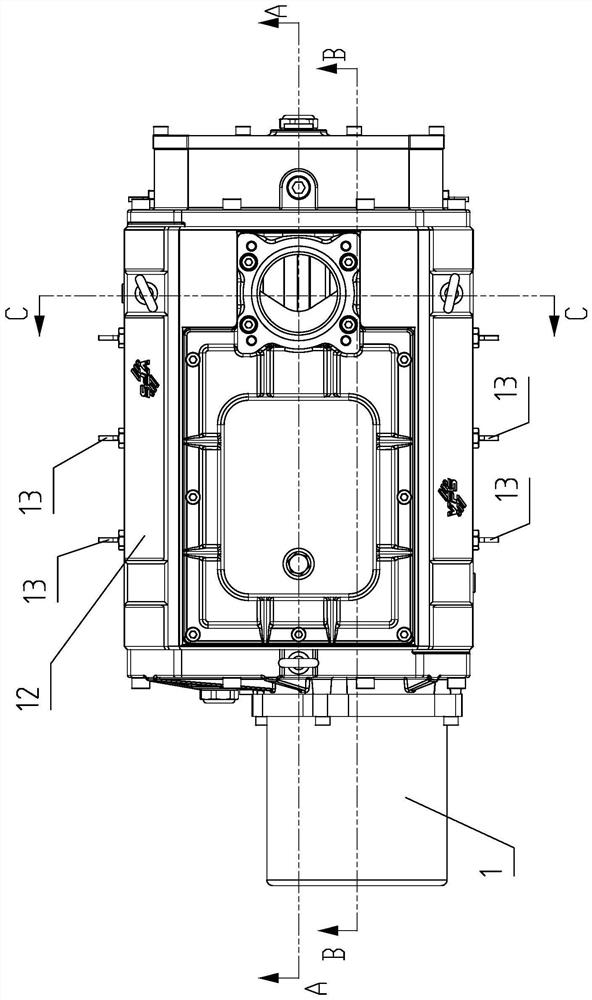

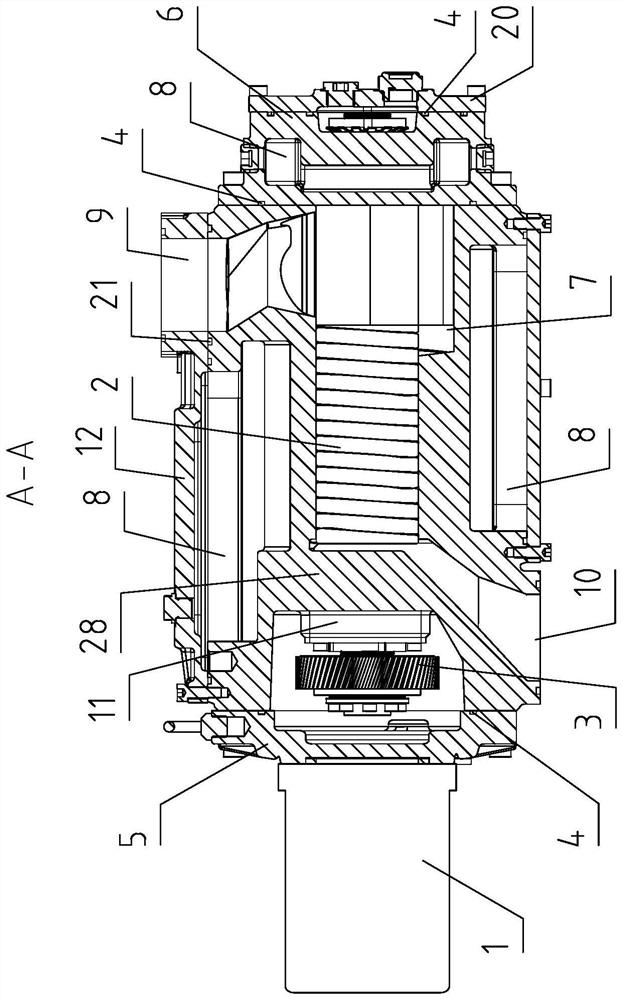

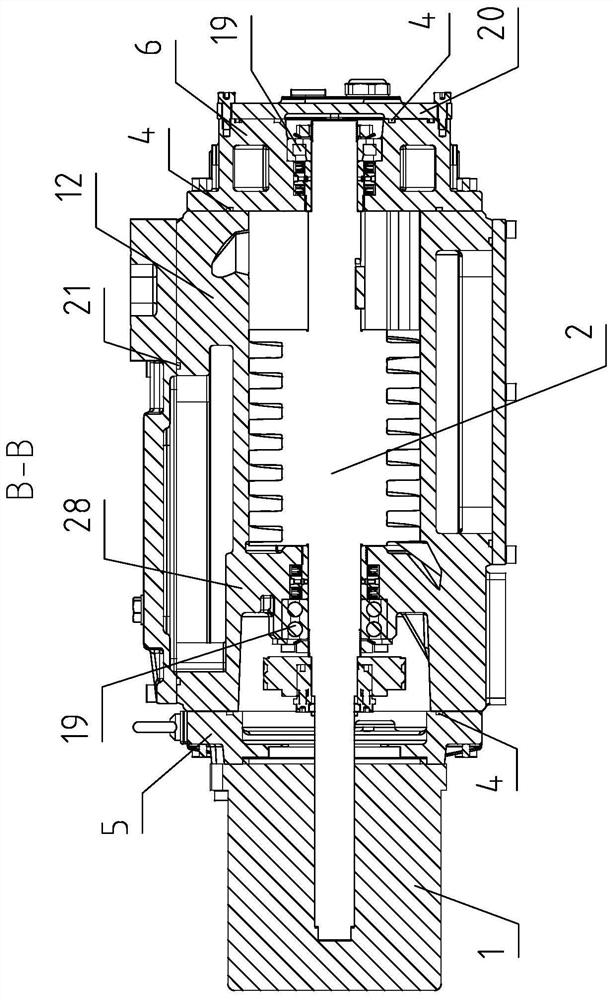

[0045] Figure 1-Figure 14 It is an embodiment of an oblique Roots-screw composite vacuum pump of the present invention. It can be seen in the figure that it is provided with a pump body 12, a front end cover 5 is provided on one side of the pump body 12, and a motor 1 is fixed on the outside of the front end cover 5. The other side of the pump body 12 is provided with a rear end cover 6, an end face sealing ring 4 is provided between the rear end cover 6 and the pump body 12, and a rear cover plate 20 is fixedly provided on the outside of the rear end cover 6.

[0046] figure 2 and image 3 It can be seen in the figure that one side of the pump body 12 is provided with a front inner cavity 26, and the other side of the pump body 12 is provided with a composite rotor inner cavity 27, and the front inner cavity 26 and the composite rotor inner cavity are 27 is provided with a pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com