A kind of bearing processing technology and bearing grease injection equipment

A bearing and equipment technology, applied in the field of bearing processing, can solve the problems of low bearing processing efficiency, waste of grease, and excessive difference in grease injection quality, etc., to improve grease injection efficiency, accurate grease injection, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

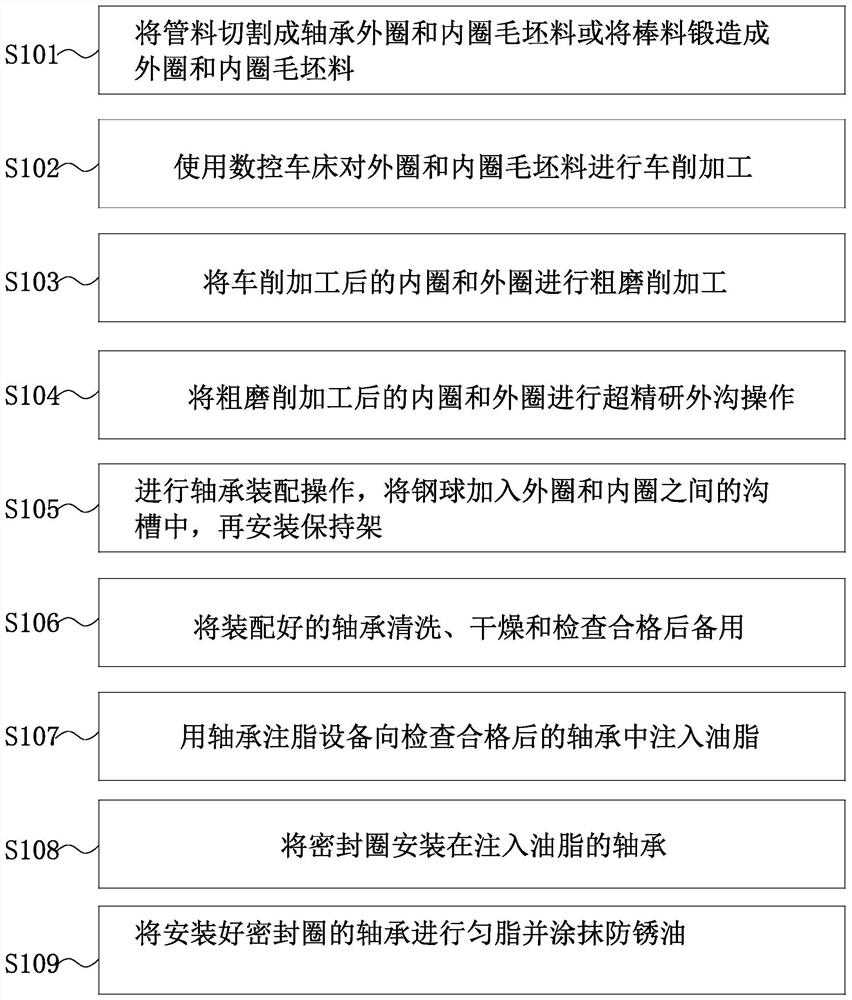

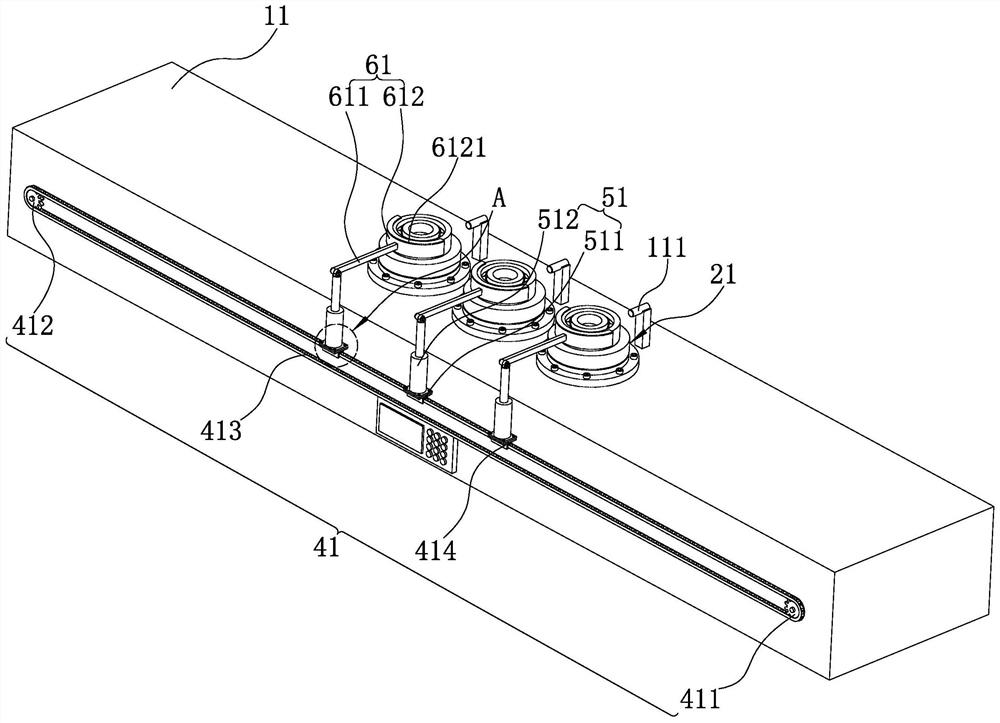

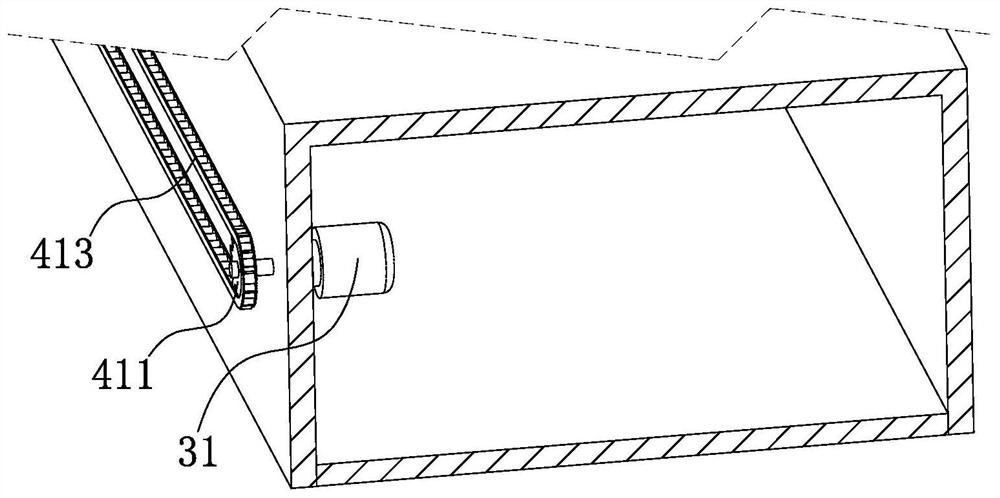

[0046] Attached to the following Figure 1-6 This application will be described in further detail.

[0047] It should be understood that with the rapid development of the industry, during the use of the bearing, the requirements for the speed, stability and vibration value of the bearing are getting higher and higher. Due to the large load and small clearance of the bearing during operation, friction and wear will occur. Therefore, the requirements for the lubrication performance of bearings are becoming more and more strict. Therefore, the requirements for the lubricating performance of bearings are becoming more and more strict. In the related art, for some small batch types of bearings or in small and micro enterprises, out of consideration of production costs, a bearing production line that can be automatically greased will not be introduced, and grease is generally injected into the bearings by manual grease injection. However, the specific location and amount of grease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com