Model construction method and device and concrete compressive strength prediction method and device

A construction method and technology of compressive strength, applied in measuring devices, using stable tension/pressure to test material strength, strength characteristics, etc., can solve problems such as insufficient accuracy, long time required, and accuracy problems, to avoid calculation. Difficulty, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

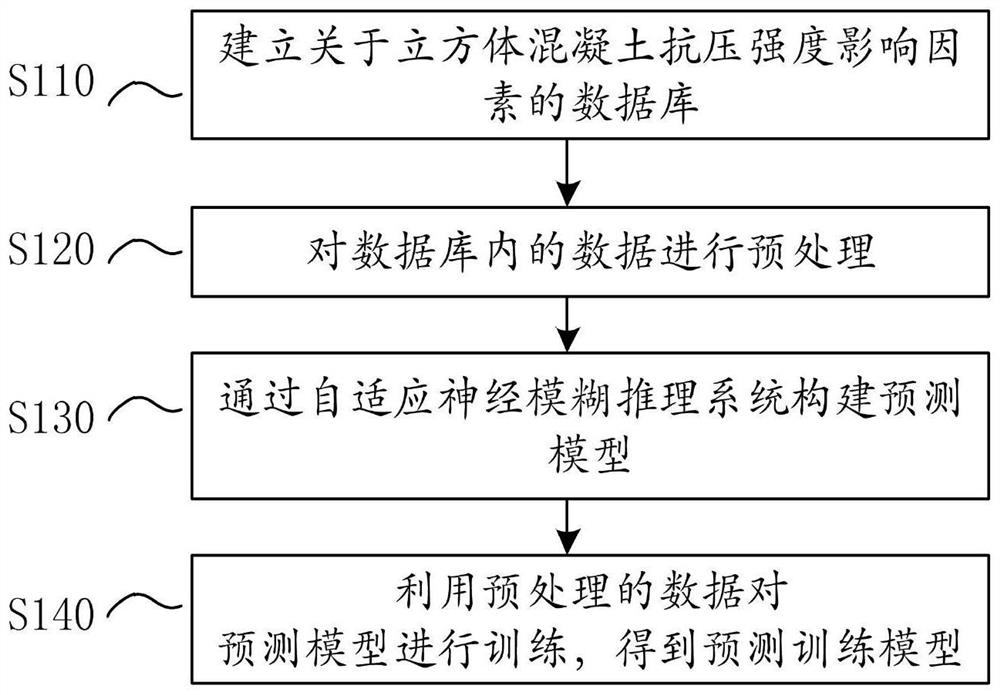

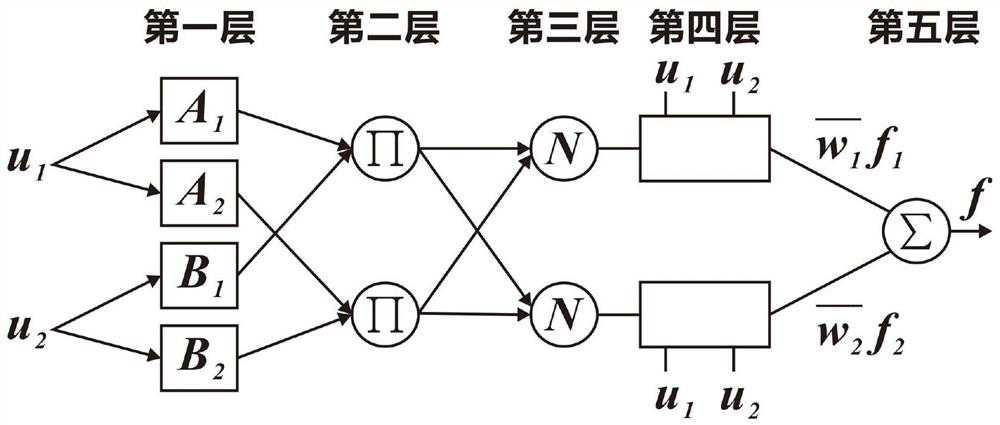

[0077] figure 1 is the flow chart of the model construction method of the embodiment of the present application, such as figure 1 As shown, the method includes the following steps:

[0078] S110, establishing a database of factors affecting the compressive strength of the cubic concrete. The database for this example was collected from existing literature, with a total of 286 samples.

[0079] Among them, the influencing factors include: cement compressive strength, cement tensile strength, concrete curing age, coarse aggregate maximum particle size, stone powder content, sand fineness modulus, water-binder ratio, water-cement ratio, water There are 11 items of quality, sand content and slump.

[0080] The above indicators are used as the quantitative input value of the model, and the cubic concrete compressive strength is used as the quantitative output value of the model.

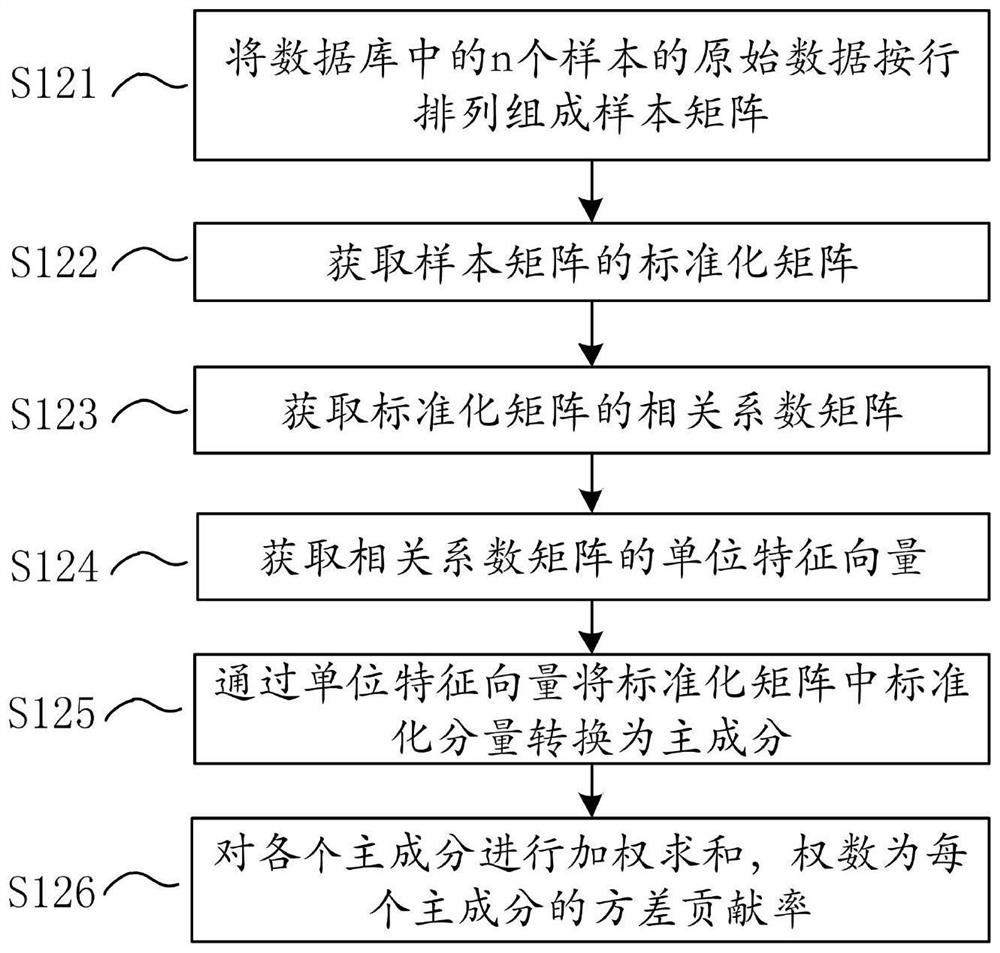

[0081] S120. Preprocessing the data in the database.

[0082] In order to evaluate the feasibilit...

Embodiment 2

[0142] The embodiment of the present application also provides a model construction device, which is used to execute the model construction method of Example 1 of the present application, such as Figure 4 As shown, the construction device includes: a database unit, a preprocessing unit, a construction unit, and a training unit.

[0143] The database unit is used to establish a database of factors affecting the compressive strength of cubic concrete.

[0144] Among them, the influencing factors include: cement compressive strength, cement tensile strength, concrete curing age, coarse aggregate maximum particle size, stone powder content, sand fineness modulus, water-binder ratio, water-cement ratio, water One or more of quality, sand content, and slump. The above indicators are used as the quantitative input value of the model to be constructed, and the cubic concrete compressive strength is used as the quantitative output value of the model to be constructed.

[0145] The p...

Embodiment 3

[0181] The embodiment of the present application also provides a method for predicting the compressive strength of concrete, which is used to predict the compressive strength of concrete using the prediction training model obtained by the model construction method in the first embodiment of the present application.

[0182] The database of this example is collected from existing literature, with a total of 286 samples, as in Example 1. The output is the compressive strength of artificial sand concrete.

[0183] Such as Figure 5 As shown, the concrete compressive strength prediction method of this example includes steps:

[0184] S210. Obtain the main influencing factors of the compressive strength of the concrete to be tested.

[0185] Among them, the main influencing factors of the compressive strength of the concrete to be tested are the cement compressive strength of the concrete to be tested, the tensile strength of the cement, the concrete curing age, the maximum parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com