A small fault detection method for a closed-loop control system of a sampling manipulator

A fault detection and closed-loop control technology, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve problems such as difficulty in detecting small faults, frequent changes in fault diagnosis speed, etc., and achieve the release of symbol constraints. , the effect of increasing the detectable fault information and improving the rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

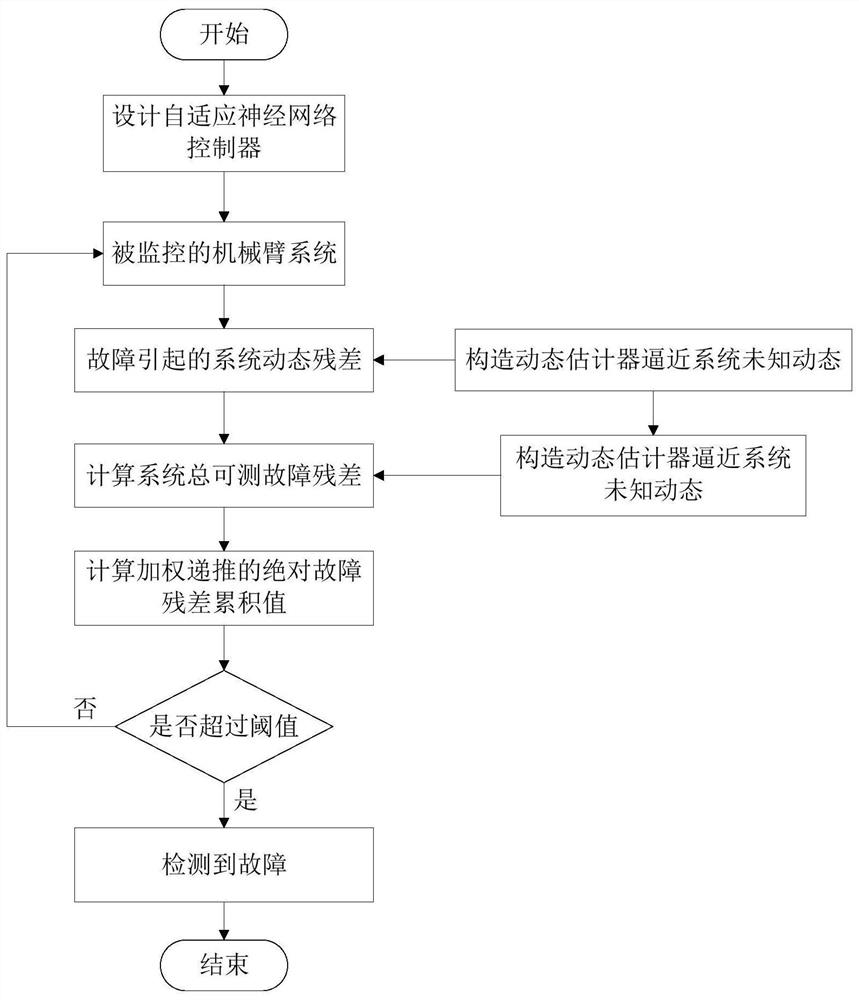

[0088] Such as figure 1 As shown, the present embodiment provides a small fault detection method of the closed-loop control system of the sampling manipulator, comprising the following steps:

[0089] S1: Establish a discrete-time single-link rigid manipulator dynamics model based on sampling data, specifically expressed as:

[0090]

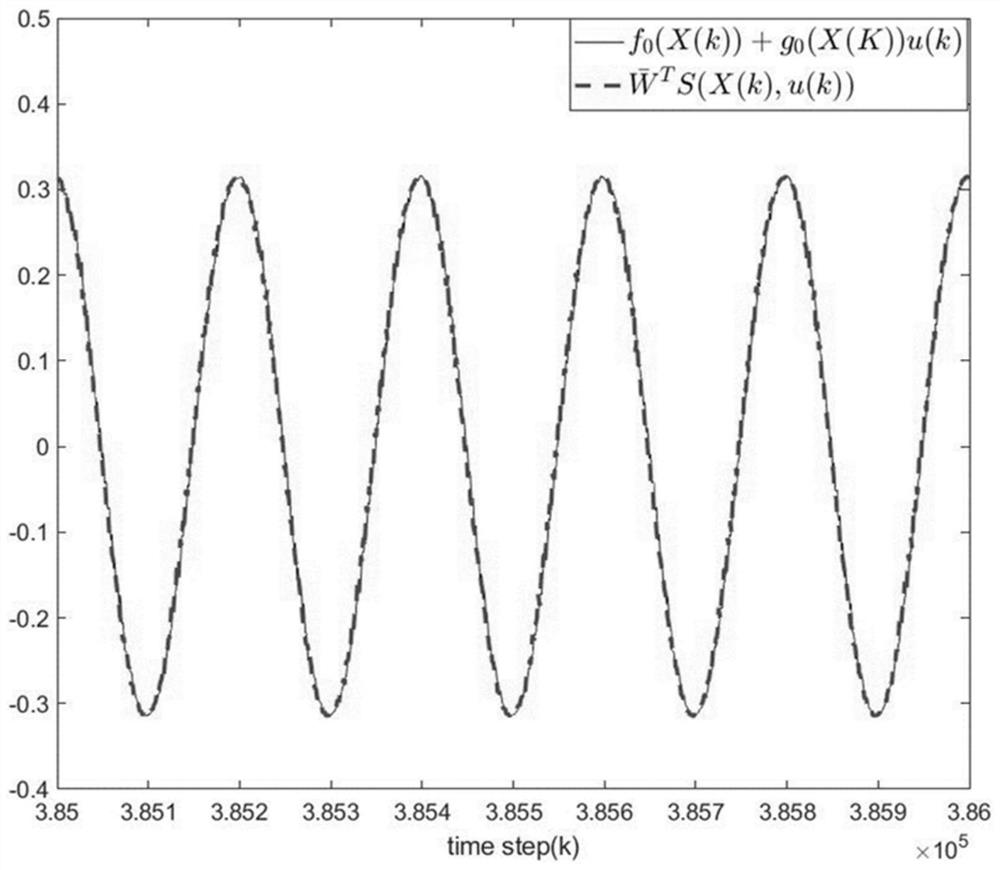

[0091] Among them, k represents the running time of the sampling discrete manipulator system, T s Indicates the sampling time interval, and the sampling time point is kT s , X(k)=[x 1 (k),x 2 (k)] T ; x 1 (k) and x 2 (k) are the joint angular displacement and joint angular velocity of the manipulator respectively. u(k) is the control torque, f 0 (X(k)) and g 0 (X(k)) is the unknown nonlinear function of the system, g 0 (X(k))=T s M(x 1 (k)) -1 , f 0 (X(k))=x 2 (k)+T s M(x 1 (k)) -1 [-V m (x 1 (k),x 2 (k))x 2 (k)-G(x 1 (k))], M(x 1 (k)) is the inertia matrix of the manipulator, V m (x 1 (k),x 2 (k)) is the centripetal...

Embodiment 2

[0134] A small fault detection system for a closed-loop control system of a sampling manipulator, including: a model building block, an adaptive neural network controller building block, a dynamic estimator building block, a total measurable fault residual calculation module, and an absolute fault residual cumulative value Calculation module, fault detection decision building block;

[0135] In this embodiment, the model building module is used to establish a data sampling-based mechanical arm dynamics model and an expected regression trajectory model;

[0136] In this embodiment, the adaptive neural network controller building block is used to construct an adaptive neural network controller;

[0137] In this embodiment, the dynamic estimator building block is used to construct a dynamic estimator to approximate the unknown dynamics of the system;

[0138] In this embodiment, the total measurable fault residual calculation module is used to calculate the total measurable faul...

Embodiment 3

[0152] This embodiment provides a storage medium, the storage medium may be a storage medium such as ROM, RAM, magnetic disk, optical disk, etc., and the storage medium stores one or more programs. A glitch detection method for a closed-loop control system of a robotic arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com