Embedded system simulation method and system for multi-robot manufacturing system

An embedded system and manufacturing system technology, applied in design optimization/simulation, constraint-based CAD, comprehensive factory control, etc., can solve problems affecting PRES+net application, PRES+net state space explosion, etc., to alleviate the state space explosion problem , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The purpose of this embodiment is to provide an embedded system simulation method for a multi-robot manufacturing system.

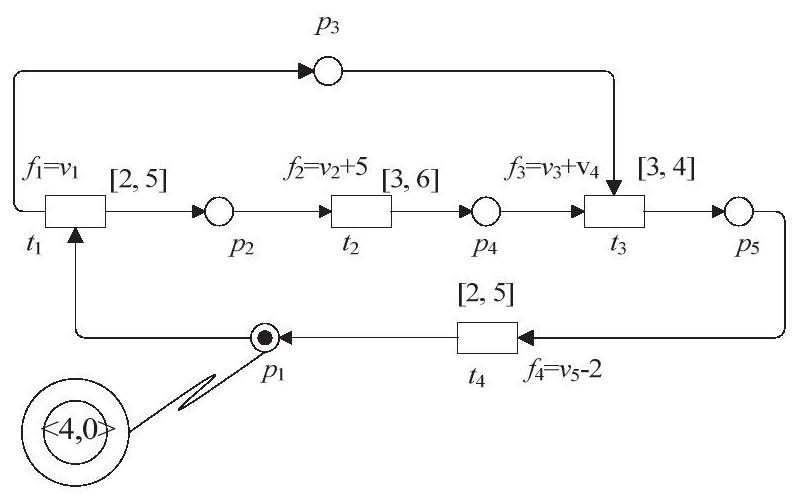

[0040] An embedded system simulation method for a multi-robot manufacturing system, wherein the manufacturing system includes a processing control system and an assembly control system sharing several robot control subsystems, including:

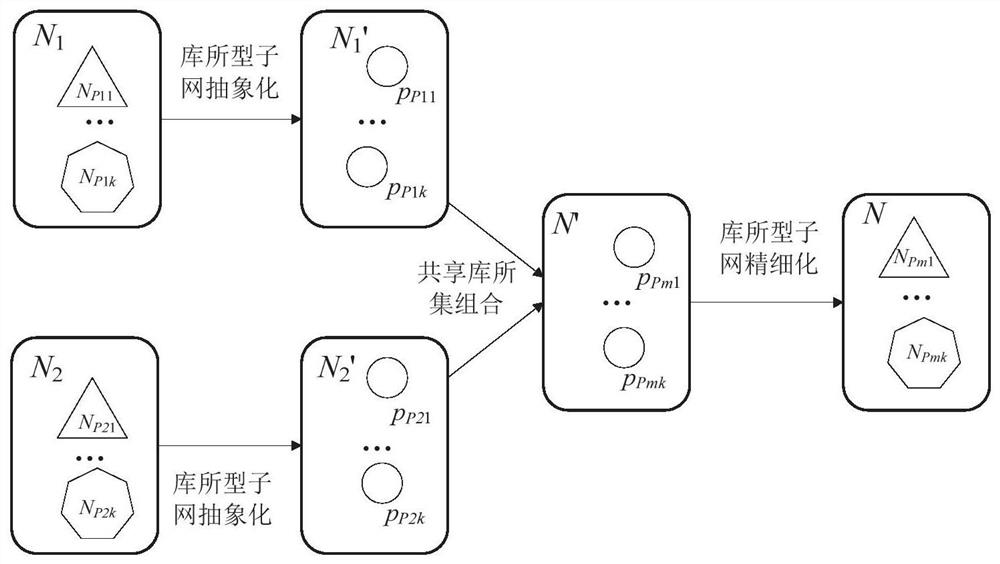

[0041] Based on the function and module division of the processing and assembly system in the manufacturing system, the PRES+net model of the processing control system and the PRES+net model of the assembly control system are respectively constructed;

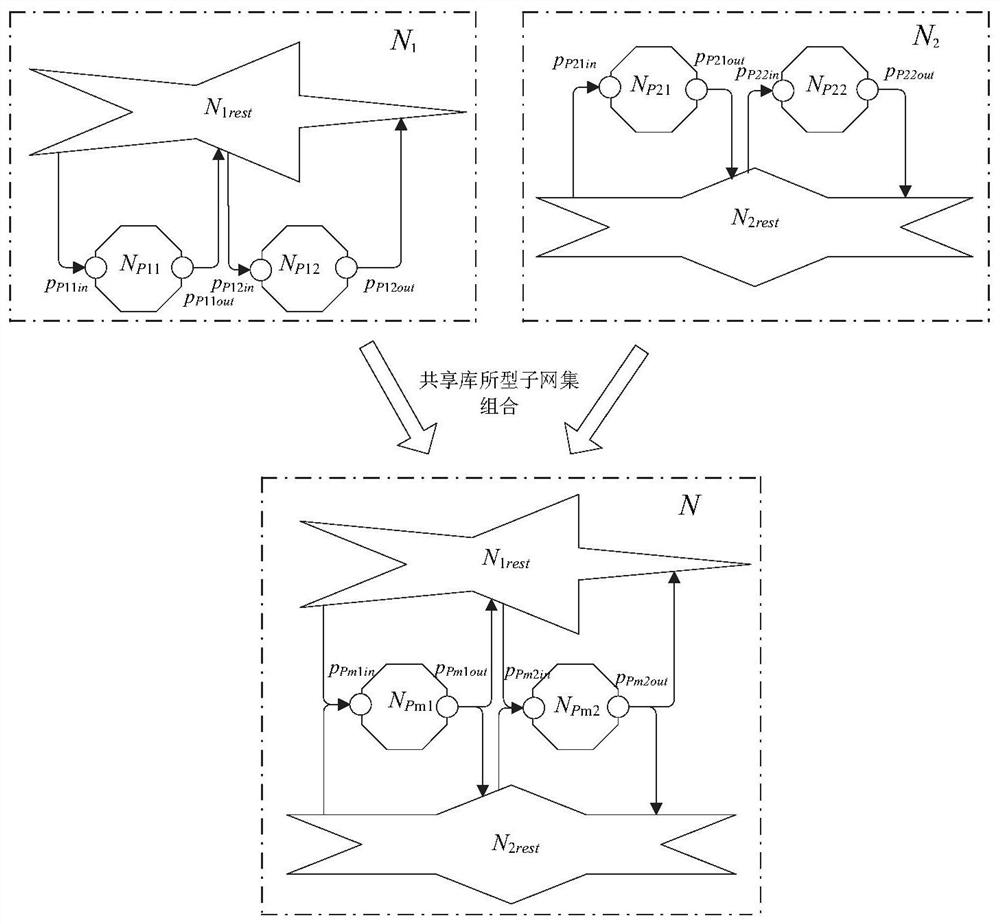

[0042] Based on the combination method of the shared place-type subnetwork set, the shared operation of the place-type subnetwork set is performed on the PRES+net model of the processing control system and the PRES+network model of the assembly control system, and the combined PRES+network model of the shared place-set set is obtained;

[0043] The embedded system...

Embodiment 2

[0246] The purpose of this embodiment is to provide an embedded system simulation system for a multi-robot manufacturing system.

[0247] An embedded system simulation system for a multi-robot manufacturing system, wherein the manufacturing system includes a processing control system and an assembly control system sharing several robot control subsystems, including:

[0248] A basic model construction unit, which is used to respectively construct a processing control system PRES+network model and an assembly control system PRES+network model based on the functions and module divisions of the processing and assembly systems in the manufacturing system;

[0249] A place-type subnet sharing unit, which is used to share the place-type subnetwork set based on the combination method of the shared place-type subnetwork set for the processing control system PRES+net model and the assembly control system PRES+net model, to obtain a shared place Set combined PRES+net model;

[0250] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com