Embedded system simulation method and system for multi-robot manufacturing system

A technology of embedded systems and manufacturing systems, applied in design optimization/simulation, constraint-based CAD, comprehensive factory control, etc., can solve the problems of PRES+ network state space explosion, affecting PRES+ network applications, etc., to alleviate the state space explosion problem , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The purpose of this embodiment is to provide an embedded system simulation method for a multi-robot manufacturing system.

[0040] An embedded system simulation method for a multi-robot manufacturing system, wherein the manufacturing system includes a processing control system and an assembly control system sharing several robot control subsystems, including:

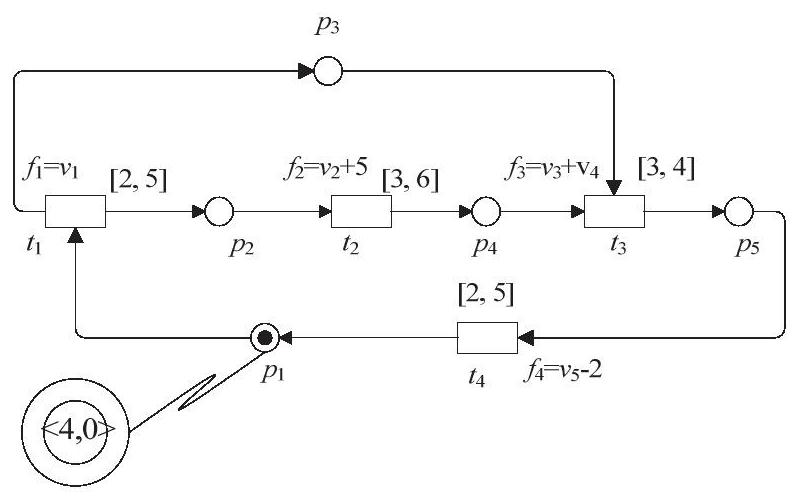

[0041] Based on the function and module division of the machining and assembly systems in the manufacturing system, the PRES+ net model of the machining control system and the PRES+ net model of the assembly control system are constructed respectively;

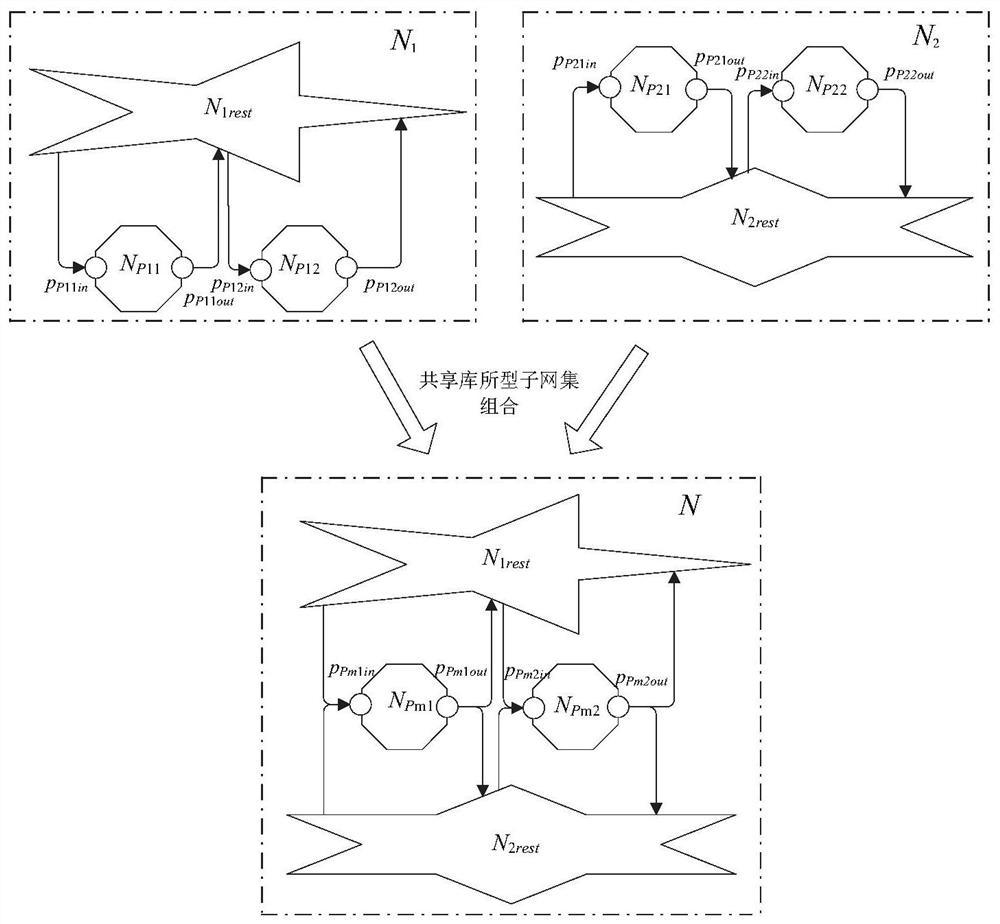

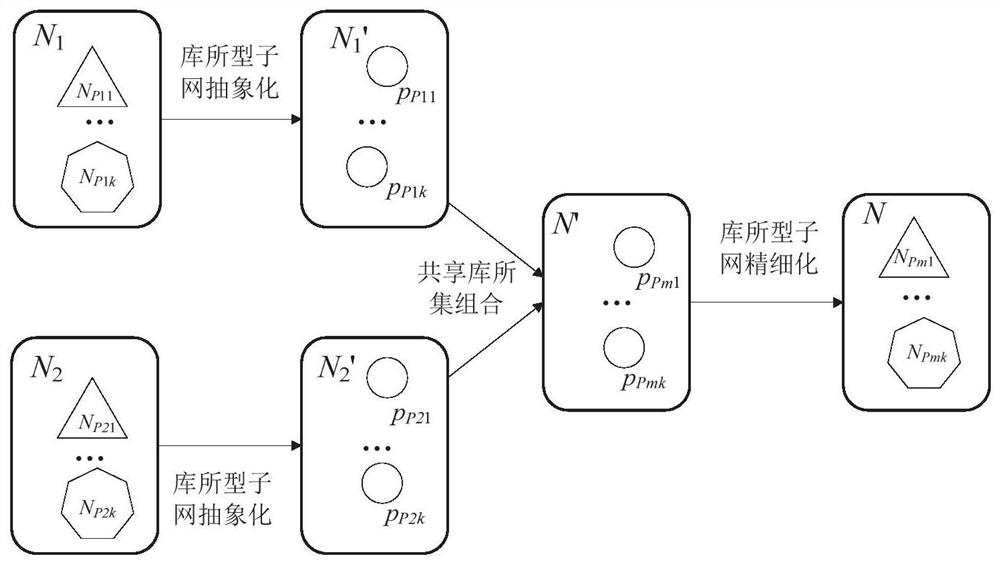

[0042] Based on the combination method of the shared place type subnet set, the shared operation of the place type subnet set is performed on the PRES+net model of the machining control system and the PRES+net model of the assembly control system, and the PRES+net model of the shared place set combination is obtained;

[0043] Based on the combined PRES+net model...

Embodiment 2

[0246] The purpose of this embodiment is to provide an embedded system simulation system for a multi-robot manufacturing system.

[0247] An embedded system simulation system for a multi-robot manufacturing system, wherein the manufacturing system includes a processing control system and an assembly control system sharing several robot control subsystems, including:

[0248] The basic model construction unit is used to construct the processing control system PRES+net model and the assembly control system PRES+net model respectively based on the function and module division of the processing and assembly systems in the manufacturing system;

[0249] The place type subnet sharing unit is used to share the place type subnet set based on the shared place type subnet set combination method on the machining control system PRES+net model and the assembly control system PRES+net model, and obtain the shared place type subnet set. Set combined PRES+net model;

[0250] The simulation u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com