A kind of impregnating solution, negative plate and battery for dry charge battery negative plate treatment

A battery negative electrode and impregnating liquid technology, which is applied to lead-acid battery electrodes, secondary battery charging/discharging, secondary batteries, etc., can solve problems such as long discharge time, increased internal resistance of the plate, and poor hydrophobicity of the negative plate. Achieve the effect of washing-free drying process, enhancing anti-oxidation and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The negative plate is formed by the externalization process, and the charge and discharge currents of each stage are calculated according to the effective area of the negative plate. The steps are as follows:

[0029] (1) Reverse charging: use 4~5mA / cm 2 The current reverse charge for 0.5h;

[0030] (2) Multi-stage charging: use 6mA / cm first 2 The current is charged for 1.0h; then use 12mA / cm 2 The current charged for 8.0h; then with 9mA / cm 2 The current is charged for 5.0h; the final charge is 6mA / cm 2 The current is charged for 4.5h;

[0031] (3) High current instantaneous discharge: at 50mA / cm 2 The current discharge 1.0min.

[0032] Pour butylated hydroxyanisole into the 25% ethanol solution by volume and stir for 6-8 minutes to prepare immersion solution 1. The mass ratio of butylated hydroxyanisole in immersion solution 1 to 25% ethanol by volume is 5:95.

[0033] The formed negative plates are placed at intervals of 1-2 mm, immersed in the above-mentione...

Embodiment 2

[0037] The negative plate is formed by the externalization process, and the charge and discharge currents of each stage are calculated according to the effective area of the negative plate. The steps are as follows:

[0038] (1) Reverse charging: use 4~5mA / cm 2 The current reverse charge for 0.5h;

[0039] (2) Multi-stage charging: use 6mA / cm first 2 The current is charged for 1.0h; then use 12mA / cm 2 The current charged for 8.0h; then with 9mA / cm 2 The current is charged for 5.0h; the final charge is 6mA / cm 2 The current is charged for 4.5h;

[0040] (3) High current instantaneous discharge: at 50mA / cm 2 The current discharge 1.0min.

[0041] First, pour butylated hydroxyanisole into a 25% volume concentration ethanol solution and pre-stir for 1 to 3 minutes, then add citric acid, and continue stirring for 6 to 8 minutes to prepare dipping solution 2. In dipping solution 2, butylated hydroxyanisole, The mass ratio of 25% ethanol and citric acid was 5:0.5:94.5.

[00...

Embodiment 3

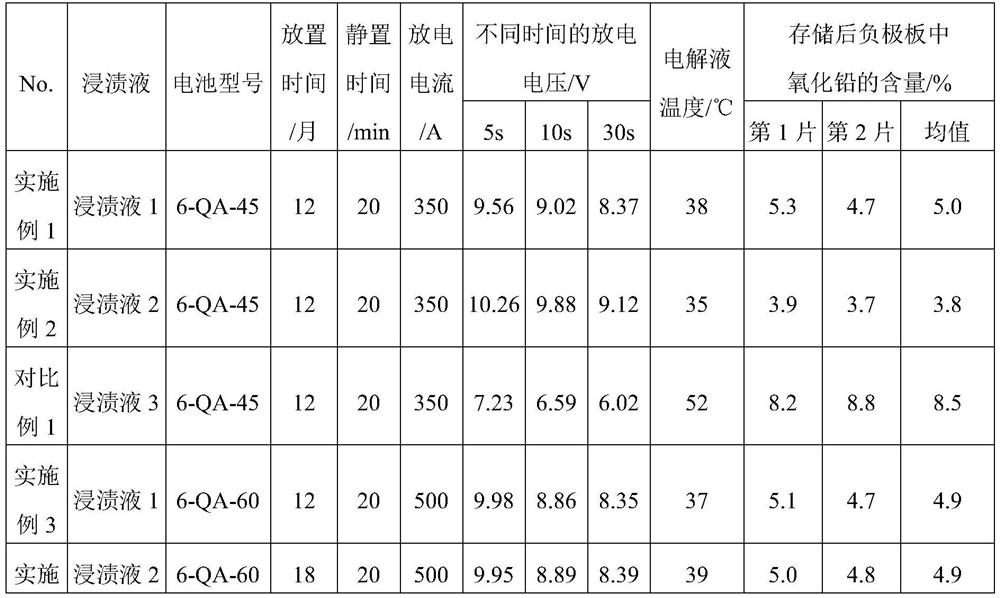

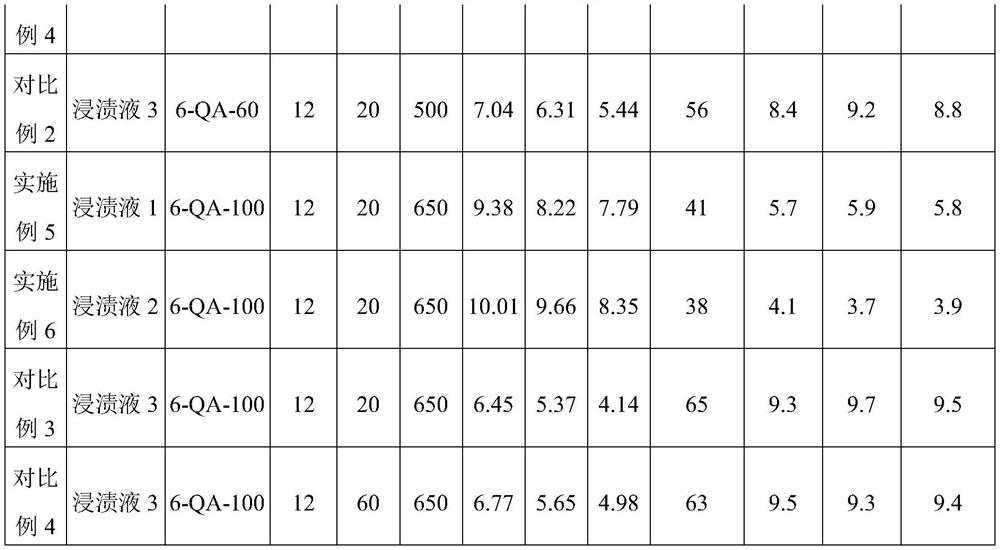

[0055] The negative plates that meet the requirements of dry load performance in Example 1 are assembled into lead-acid batteries, and the model of the lead-acid battery is 6-QA-60. After being placed in an environment with a humidity of not more than 80% for 12 months, the injection density into the lead-acid battery is 1.280±0.005g / cm 3 of sulfuric acid electrolyte, adjust the liquid level to the specified value, and discharge it with a current of 500A for 30s after standing for 20min. The standard requires that the discharge voltage within 30s is not lower than 7.2V. The voltage value of the lead-acid battery at 5s, 10s and 30s was tested and recorded. At the same time, the lead oxide content of the two negative plates was detected. The results are shown in Table 1. The electrolyte temperature before discharge is 37°C, and there is no acid overflow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com