Tree saw

A saw chain and trigger technology applied to tree saws. It can solve problems such as unfavorable and safe position cutting, unfavorable cutting ground or narrow space operation, and inability to adjust the handle angle, so as to avoid scratches and operate flexibly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

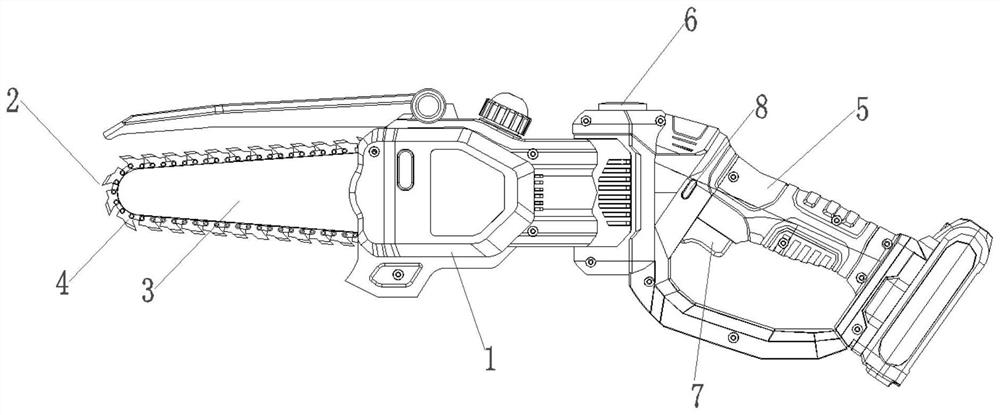

[0030] Such as Figure 1-5 As shown, a tree saw, including:

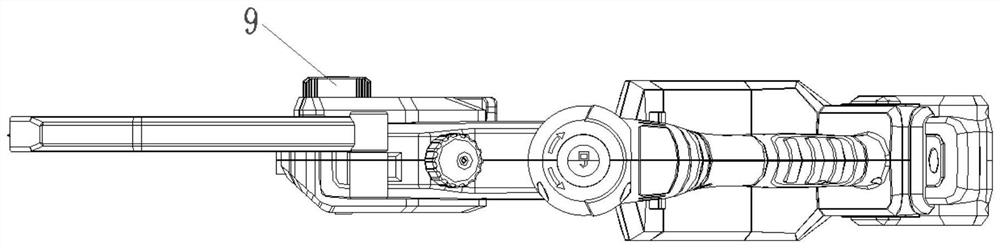

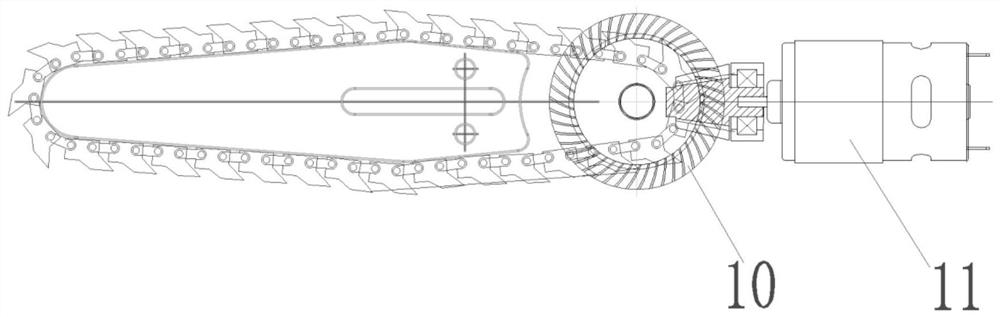

[0031] The body 1, the body 1 is disposed on the body 1, and the drive mechanism 11 is connected to the saw chain mechanism 2 and the circuit is driven when the circuit saw is in a pathway state, and the body 1 and the rotary button 6 Connection; as a specific embodiment, the drive mechanism 11 of the present embodiment includes a motor, which can be powered by a DC power source or AC power supply. The saw chain mechanism 2 includes a support plate 3 and a saw chain 4, a groove opened on the support plate 3. The saw chain 4 is provided, the saw chain 4 is engaged with the gear 10, and the motor is connected to the gear 10 by the existing transmission gear 10, and the saw chain 4 is pulled by the saw chain 4, and the saw chain mechanism 2 can also use other conventional structures. Ensure that the cutting function can be achieved;

[0032] The handle 5, the handle 5 is connected to the body 1, and the h...

Example Embodiment

[0039] Example 2

[0040] The difference from the first embodiment is that the tree saw of the present embodiment does not need to perform a mechanical structure, no need to provide the trigger locking portion 12, and simply set the open circuit switching switch on the body 1 or the handle 5. 15, the handle 5 is provided on the handle 5, which is a circuit of the trigger, and the trigger 7 is provided on the trigger 7, and the handle switch 14 and the open switch 15 are connected to the switch circuit, respectively, through the handle switch 14 and the open switch 15. The control switching circuit is turned on, and the shut-off switch 15 is turned off when the switch circuit is turned on, the body 1 or the handle 5 is turned off, and the switch circuit is turned off, so that the switch circuit is in a discontinuation, the drive mechanism 11 cannot start, the saw chain Institution 2 can not run, such as Figure 6 with Figure 7 A shows that the motor is powered by an AC power supply. W...

Example Embodiment

[0042] Example 3

[0043] The difference between the present embodiment and the second embodiment is that the motor of the present embodiment is powered by a DC power supply, and the open circuit switch 15 is provided on the body 1 or the handle 5, and the switch circuit is provided on the handle 5, the switch circuit is a tree. The saw circuit, the trigger 7 sets the interrupted handle switch 14, the handle switch 14 and the circuit switch 15 respectively connected to the switch circuit, and the switching circuit is controlled by the handle switch 14 and the switching circuit of the switch circuit. The start and stop of the saw chain mechanism, the control panel is also set up on the switch circuit, and the role of the control board is to achieve overcurrent, overprofake protection, such as Figure 7 B shows that the body 1 or handle 5 of the tree saw is rotated to adjust the circuit switch 15, so that the switch circuit is in a discontinuation, the drive mechanism 11 cannot be ac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap