Plastic fracture part free sewing device

A suture device and fracture technology, which is applied in the field of free suture devices for plastic fractures, can solve problems such as low repair efficiency, secondary fracture, and low strength, and achieve the effects of improving repair efficiency, preventing displacement, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

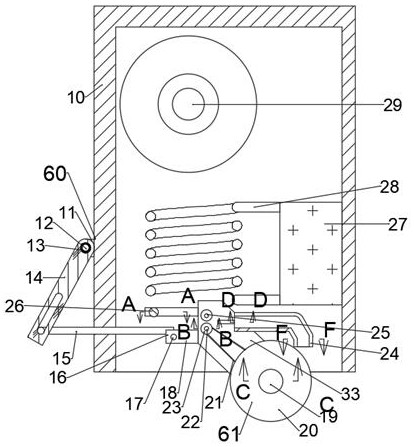

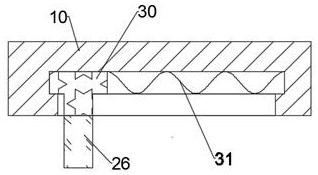

[0022] combined with Figure 1-6 The free suture device at a plastic fracture includes a working box 10, and the working box 10 is used for holding the equipment;

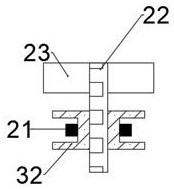

[0023] The working box 10 is fixed with a switch device 60, and the switch device 60 is used to drive the equipment. The inside of the working box 10 is provided with a gear shaft 17, and the gear shaft 17 is fixed with a repair device 61. , the repairing device 61 is used to repair the plastic fracture, the working box 10 is provided with a heating coil 28, and the heating coil 28 is used to heat the iron wire, and the working box 10 is provided with a coil 29 for rotation, so The wire reel 29 is used to place the wire coil, the switch device 60 includes a rotating rod 18 fixed on the gear shaft 17, the rotating rod 18 is fixed with a fixed plate 33, and the fixed plate 33 rotates A first roller 25 and a rotating shaft 22 are provided, a second roller 23 and a first pulley 32 are fixedly arranged on the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com