Front-end casting assembly and steering gear installation assembly connected through transition support

A transition bracket and steering gear technology, applied in the field of vehicle parts, to avoid time and economic costs and control development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

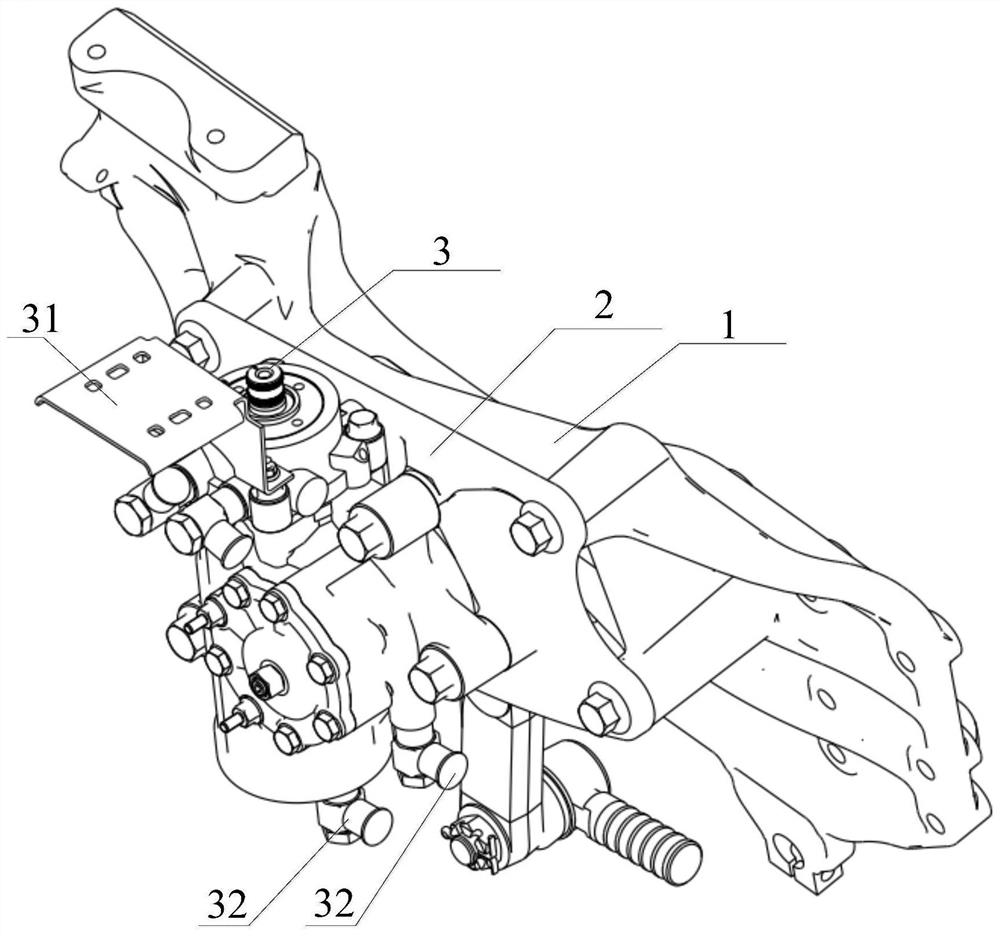

[0068] The main idea is that the front-end functional casting assembly 1 is used as the basis for modularization and generalization, the transition bracket 2 is fixed on the front-end functional casting assembly 1 through mounting bolts, and the steering gear assembly 3 is fixed on the transition bracket 2, thus forming a The front-end functional casting assembly and the steering gear installation assembly connected by the transition bracket 2. Usually, the front-end functional casting assembly 1 is used as the basic module part, and the interface of the transition bracket 2 is changed to match the steering gear assembly 3 of different interfaces, so as to meet the matching requirements of the steering gear assembly 3 with different specifications and different appearance interfaces. Front-end functional castings Assembly 1 is no longer being redeveloped.

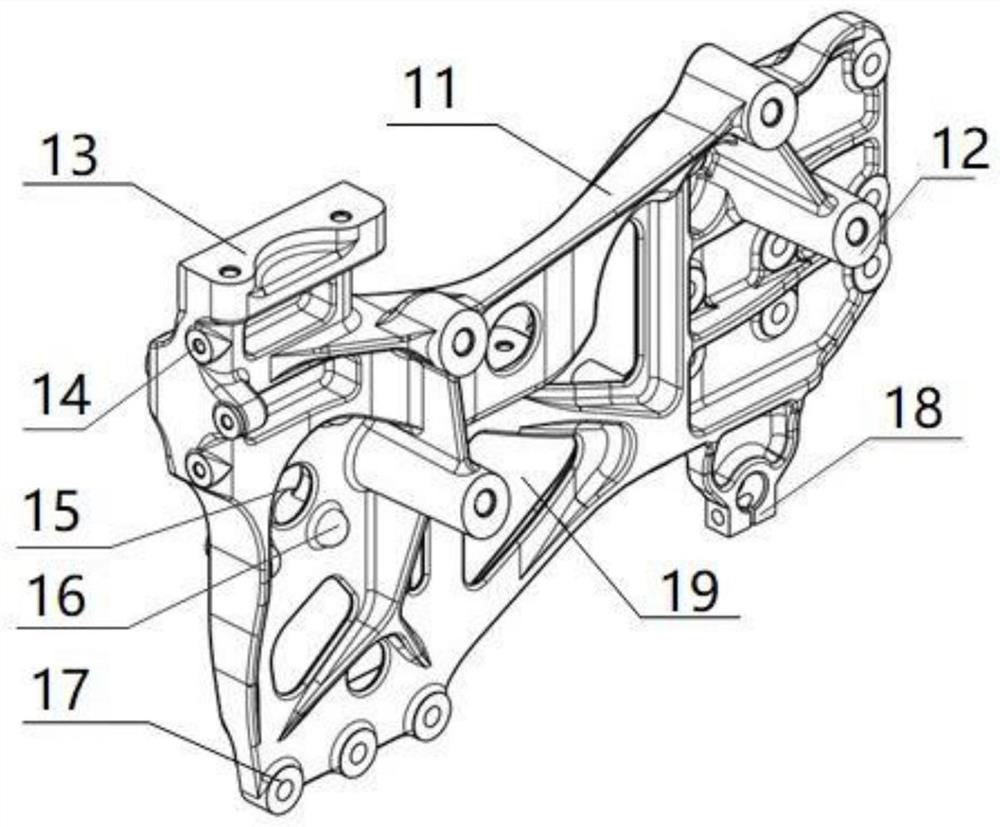

[0069] And the specific front-end function casting assembly 1 shape is as follows: figure 2 As shown, it includes cab f...

Embodiment 2

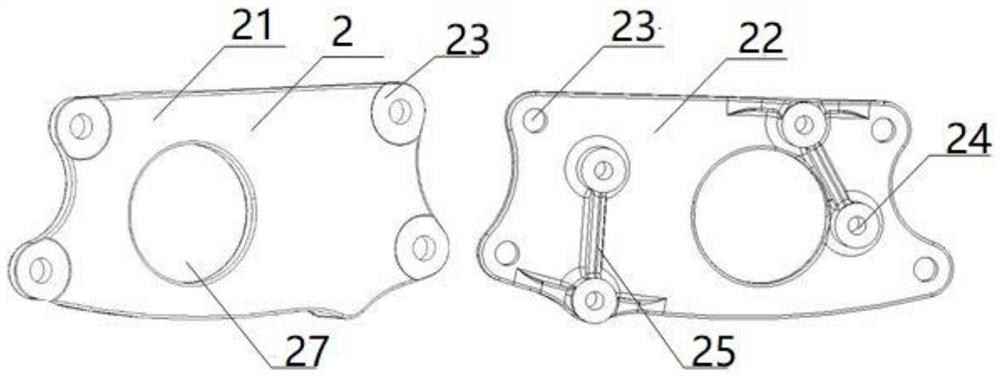

[0074] This embodiment is another structure of the transition bracket 2 .

[0075] The main idea is the same as that of Embodiment 1. The front-end functional casting assembly 1 is used as the basis for modularization and generalization. The transition bracket 2 is fixed on the front-end functional casting assembly 1 through mounting bolts, and the steering gear assembly 3 is fixed on the transition bracket 2. In this way, a front-end functional casting assembly and a steering gear installation assembly connected by the transition bracket 2 are formed. Usually, the front-end functional casting assembly 1 is used as the basic module part, and the interface of the transition bracket 2 is changed to match the steering gear assembly 3 of different interfaces, so as to meet the matching requirements of the steering gear assembly 3 with different specifications and different appearance interfaces. Front-end functional castings Assembly 1 is no longer being redeveloped.

[0076] And...

Embodiment 3

[0081]The main idea is that the front-end functional casting assembly 1 is used as the basis for modularization and generalization, the transition bracket 2 is fixed on the front-end functional casting assembly 1 through mounting bolts, and the steering gear assembly 3 is fixed on the transition bracket 2, thus forming a The front-end functional casting assembly and the steering gear installation assembly connected by the transition bracket 2. Usually, the front-end functional casting assembly 1 is used as the basic module part, and the interface of the transition bracket 2 is changed to match the steering gear assembly 3 of different interfaces, so as to meet the matching requirements of the steering gear assembly 3 with different specifications and different appearance interfaces. Front-end functional castings Assembly 1 is no longer being redeveloped.

[0082] And the specific front-end function casting assembly 1 shape is as follows: Figure 8 As shown, it includes a tow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com