Pneumatic puncture intelligent heating drinking water connector

An intelligent heating and pneumatic technology, applied in engine components, engine sealing, packaging, etc., can solve the problems of water splashing in the water storage tank, the drinking water connector cannot be connected to the water storage device, and the drinking water connector cannot be fixed with the water storage device. To achieve the effect of ensuring the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

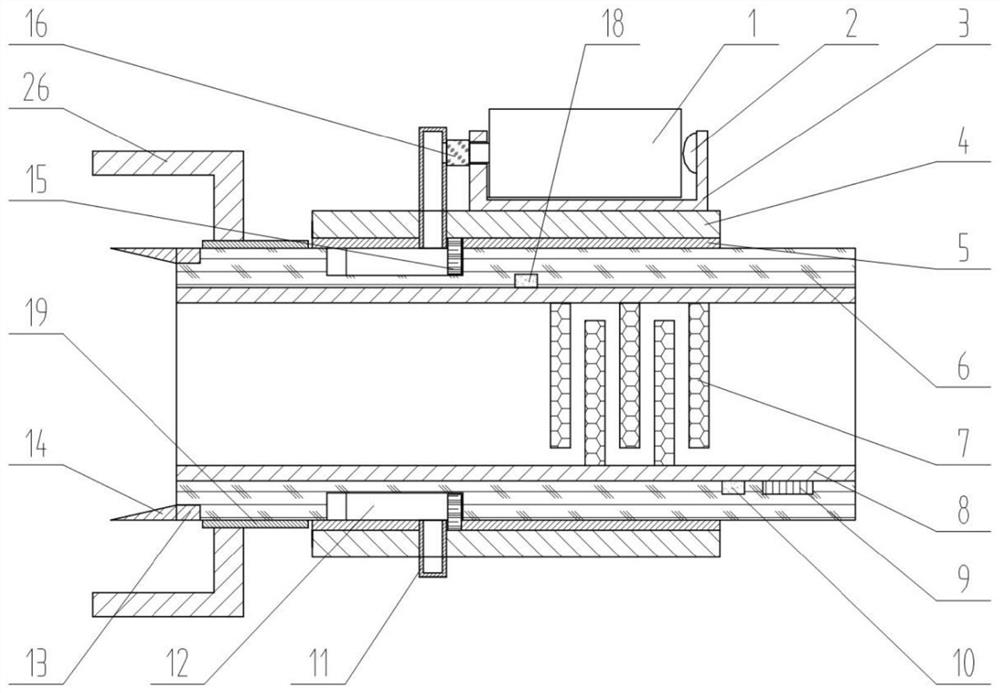

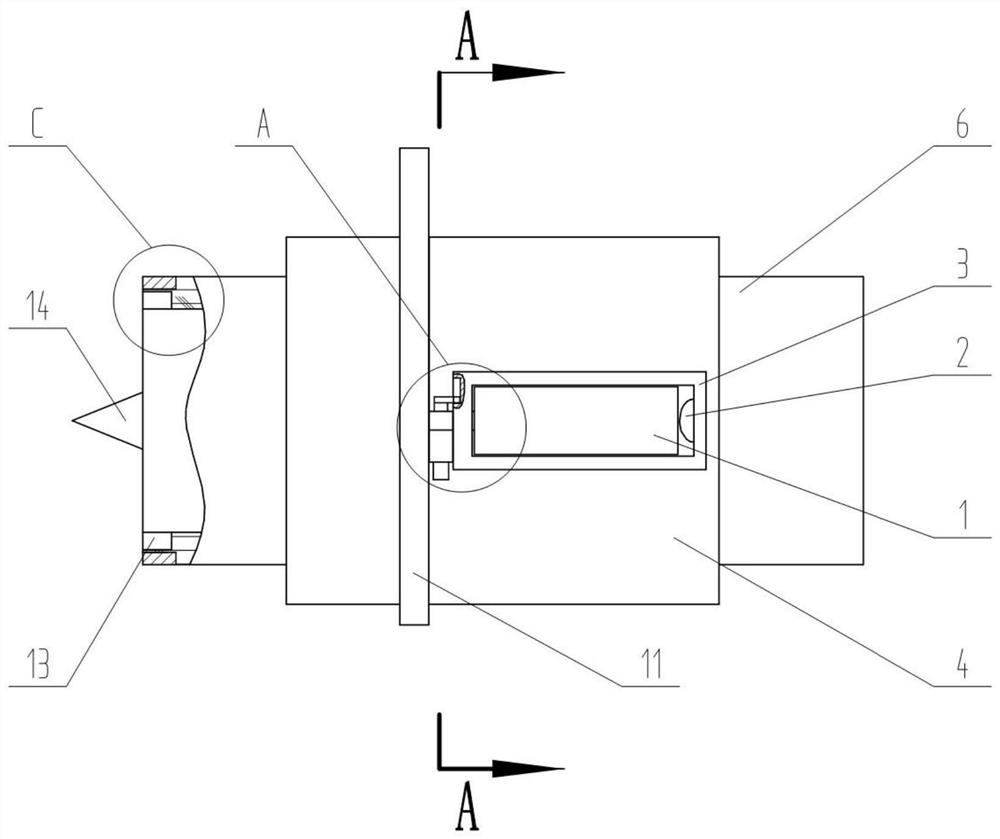

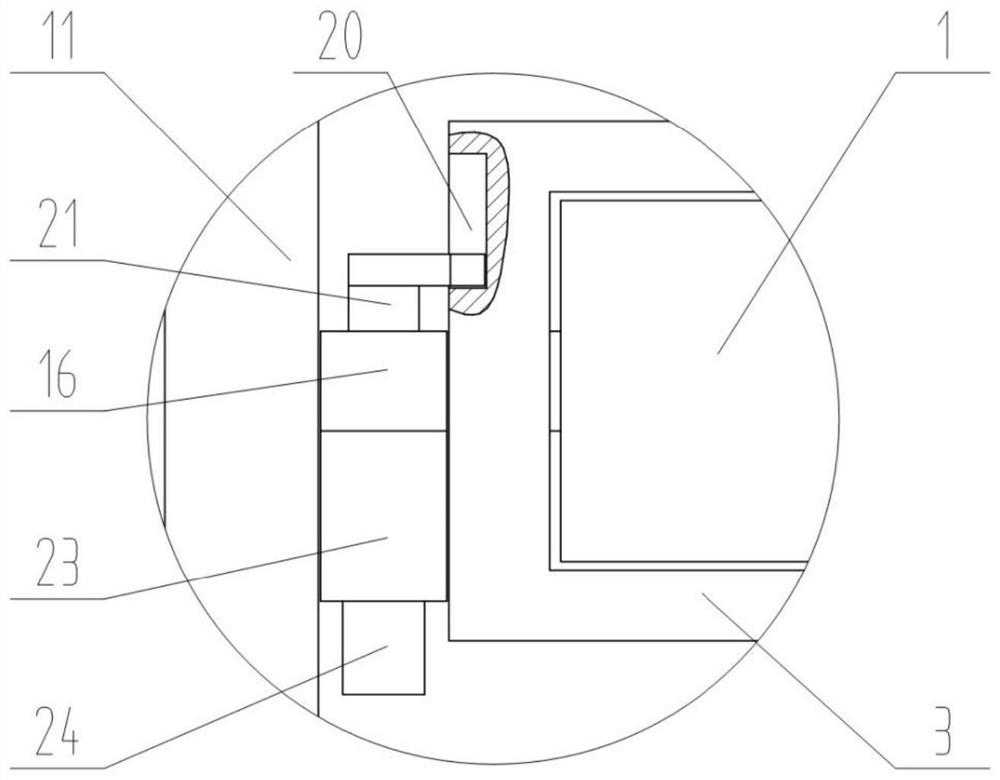

[0030] Such as Figure 1-8 As shown, the present invention provides a pneumatic puncture intelligent heating drinking water joint. The drinking water joint passes through the sealing cover 26 of the water storage device and communicates with the water storage device. The casing 6 and the outer casing 4 are slidingly connected in a limited position; the outer wall of the inner casing 6 is equidistantly provided with a plurality of pneumatic grooves 12, and the outer wall of the outer casing 4 is fixedly connected with a driving part, and the driving part communicates with the pneumatic groove 12; 6 and the outer sleeve 4 are provided with a sealing layer 5, and the sealing layer 5 is fixedly connected with the outer sleeve 4; the water inlet end of the inner sleeve 6 is fixedly set with a puncture piece; the water outlet of the inner sleeve 6 is fixedly connected with a heating part, and the heating part is located in the inner casing 6; the outer wall of the inner casing 6 ins...

specific Embodiment approach

[0050] Specific implementation method: first press the compressed gas cylinder 1 filled with gas into the cylinder base 3, pull the adjustment handle 24, make the gas sealing plate 16 block the gas nozzle 17, open the switch of the gas nozzle 17; withstand the penetration point 14 The sealing cover 26 of the water storage device, the inner tube is retracted to the rear end, the adjusting handle 24 is pushed to the bottom, the gas in the compressed gas cylinder 1 is discharged, the compressed gas is filled into the pneumatic tank 12 through the air guide tube 11, and the inner tube is driven to impact forward and inserted into the storage tank. Water container sealing cover 26, drinking water in the water container can be drawn out; After the inner tube is inserted into the water container sealing cover 26, it is limited by the limit block 15 that is arranged on the pneumatic groove 12 on the outer sleeve 4, and the inner tube stops at a reasonable depth, the first sealing film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com