Cloth multi-stage dust removal device for textile processing

A dust removal device and cloth technology, which is applied in textiles and papermaking, fabric surface trimming, mechanical cleaning, etc., can solve the problems that dust cannot be removed, and the dust removal effect of cloth is general, so as to achieve the effect of improving aesthetics and efficient dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

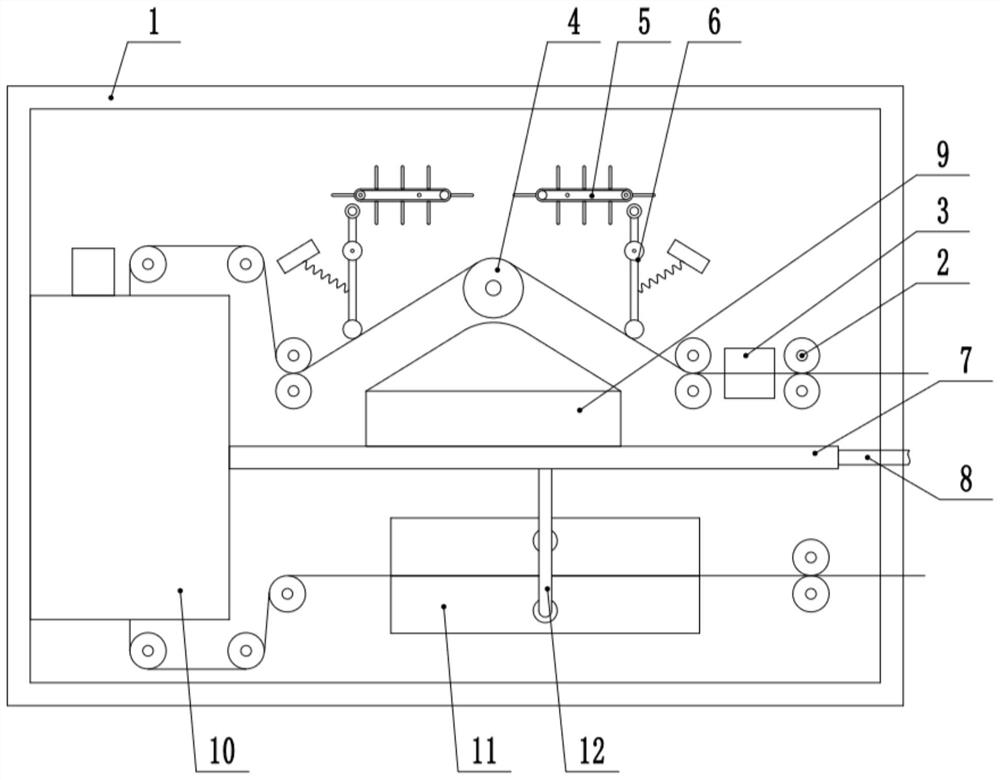

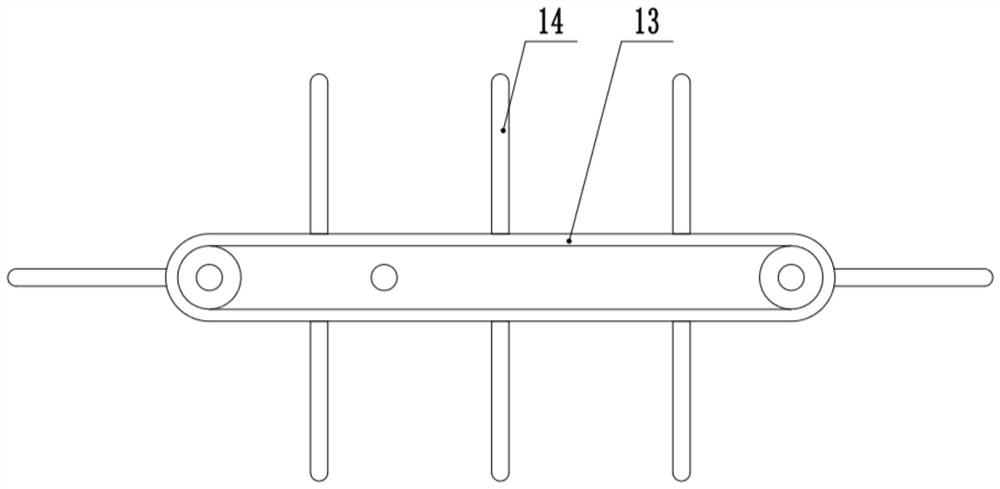

[0028] see Figure 1-5 , a multi-stage dust removal device for fabrics used in textile processing, comprising a dust removal box 1, a plurality of groups of conveying rollers 2 are arranged in the dust removal box 1, and the plurality of groups of conveying rollers 2 are used for conveying fabrics, and also includes: a vibration set in the dust removal box 1 The dust removal assembly, the high pressure difference mobile dust removal device 10 and the negative pressure dust collection mechanism, the dust removal box 1 is provided with a fixed frame 7 and a negative pressure pipe 8, and the negative pressure pipe 8 passes through the dust removal frame and is connected with the vibration dust removal assembly and the high pressure difference mobile dust removal device. 10 is connected with the negative pressure dust collecting mechanism, and the negative pressure pipe 8 is connected with the external negative pressure source, wherein,

[0029] The vibration dust removal assembly...

Embodiment 2

[0038] see Figure 1-5, On the basis of Embodiment 1, a tensioning roller 4 is also set in the dust removal box 11, and the tensioning roller 4 is rotatably connected with the dust removal box 1. There are two sets of vibration dust removal components, and the tension roller 4 is located in the two sets of vibration dust removal components. Between the components, the upper negative pressure cover 9 is also located between the two groups of vibration dust removal components. The arrangement of the tension roller 4 can increase the tightening of the cloth, which is convenient to increase the vibration effect of the vibrating dust removal component on the cloth, and can improve the dust removal ability.

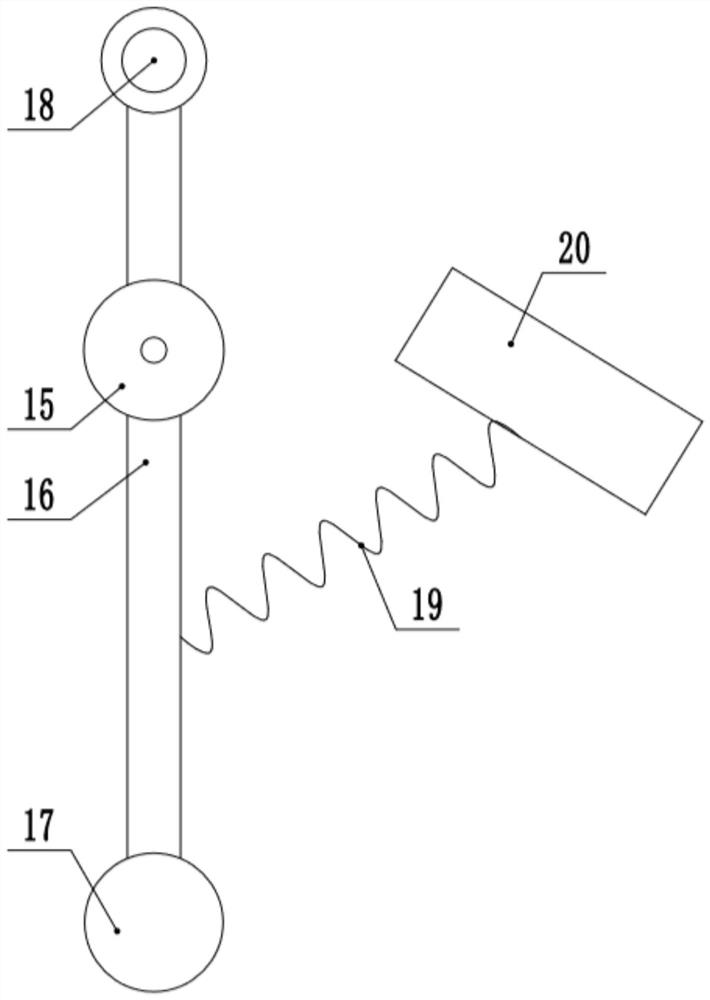

[0039] In addition, in an implementation of this embodiment, the first air transmission pipe 30 and the second air transmission pipe 31 both adopt the coil spring 19 pipe, and when the mobile dust removal is realized, the first air transmission pipe 30 and the second air transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com