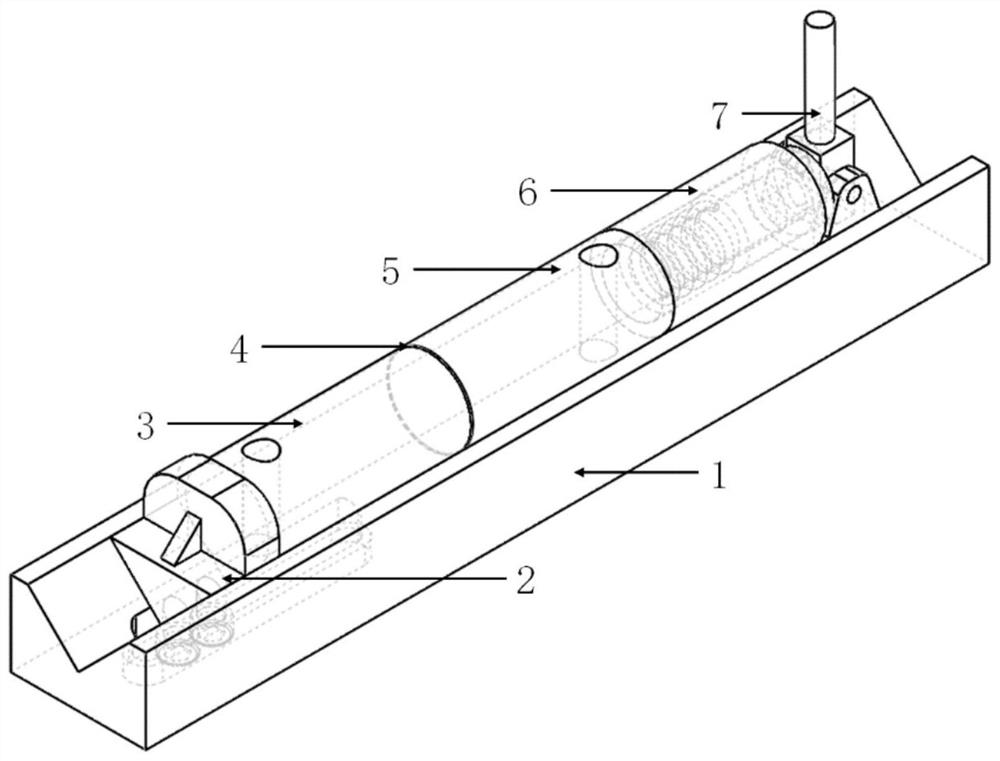

Rapid sample preparation device and method for coating bonding strength test sample

A combination of strength and sample testing technology, applied in the field of coating materials and spraying technology, can solve the problems of incomplete sample length, difficulty in increasing speed, and inability to achieve rapid sample preparation and consistency of finished products. Speed and consistency issues, the effect of increasing sample preparation speed and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

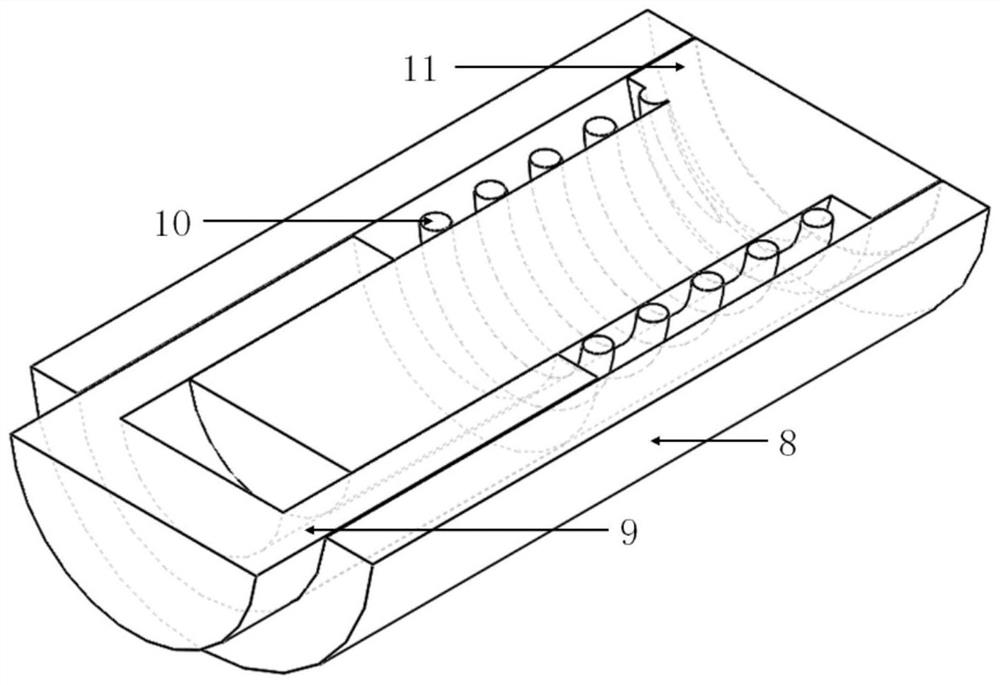

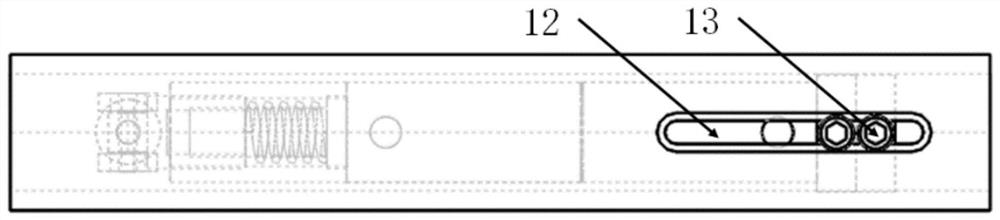

Method used

Image

Examples

Embodiment

[0071] Two groups of coating bonding strength test samples were prepared by using the method of the present invention and the traditional method respectively, with 5 samples in each group, and the coating parameters of all samples were consistent. Use a universal mechanical testing machine to generate two tension-displacement curves according to the thermal spraying-tensile bond strength measurement standard (GBT8642-2002) ( Figure 5 , Figure 6 ). Through data processing, draw the sample binding strength mean value that uses the inventive method sample preparation to be 35.5Mpa, and variance is 10.6Mpa 2 ; The average value of the bond strength of the sample prepared by the traditional method is 34.6Mpa, and the variance is 85.8Mpa 2 .

[0072] By comparing the mean values and variances of the bonding strengths of the two groups of samples, it can be seen that although the method of the present invention is used to prepare samples, although the bonding strength of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com