Telescopic sleeve-free edge sealing device for composite board processing

An edge banding device and telescopic technology, which is applied to presses, manufacturing tools, presses, etc. that use rotating pressure components, can solve the problems of affecting the edge banding effect of composite panels, rapid adjustment of the spacing between pressure rollers, and single internal adjustment methods. , to achieve a wide range of adjustment and application, simple and convenient operation, and a wide range of adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

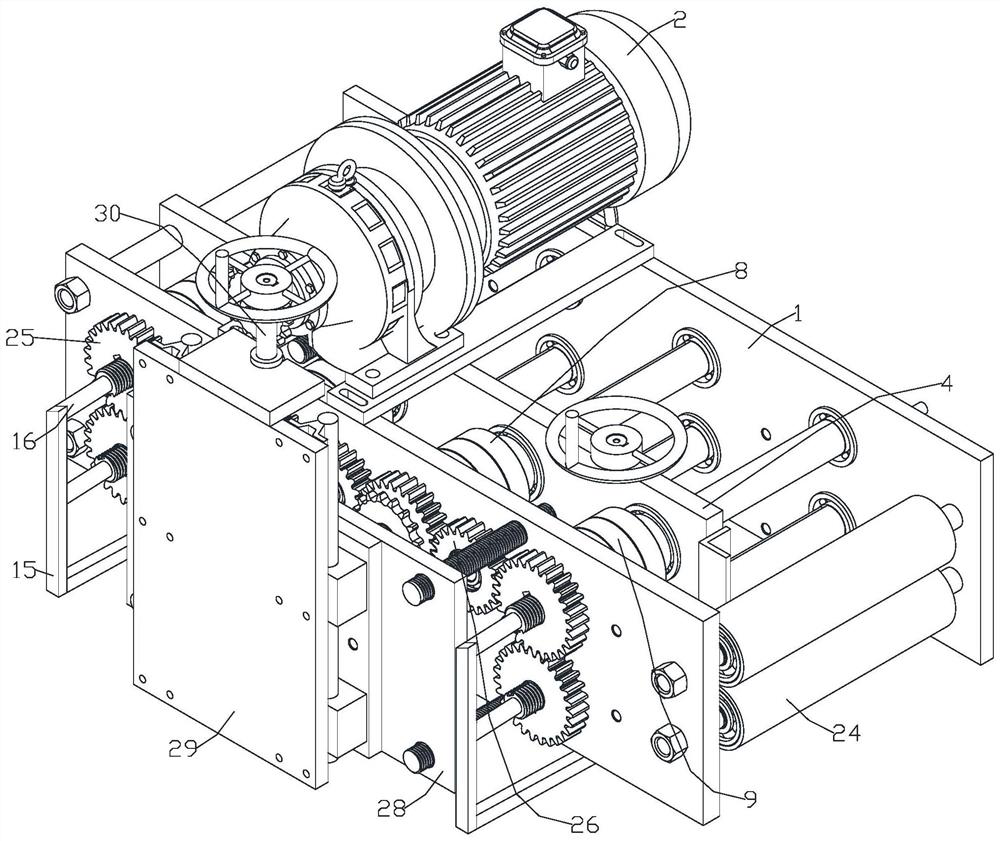

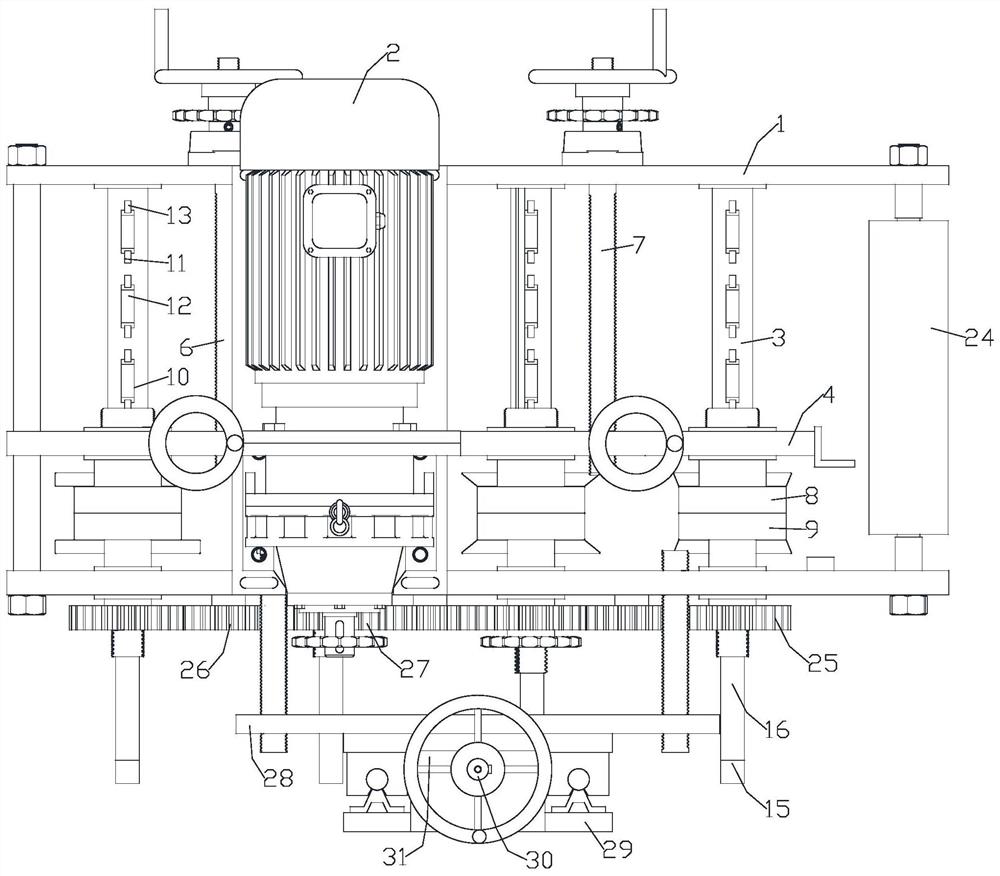

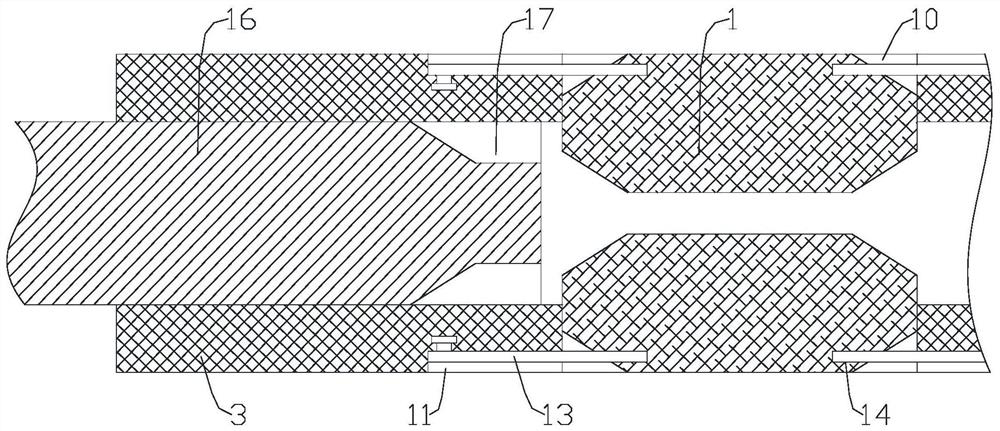

[0027] Embodiment: By rotating the first adjusting screw rod 6 and the second adjusting screw rod 7, people control the translation adjustment of the first internal adjustment partition plate 4 and the second internal adjustment partition plate 5 inside the outer casing 1, and drive the side during translation. Translate to the linkage extrusion mechanism, thereby driving the elastic support module to extrude and expand. The distance between the lateral mounting plate 28 and the lateral fixing plate 29 and the outer casing 1 is adjusted and selected according to the length of the lateral linkage extrusion mechanism, so as to ensure that the entire device is adjusted without affecting the expansion and contraction of the lateral linkage extrusion mechanism. Install.

[0028] A telescopic sleeveless edge banding device for composite panel processing of the present invention is composed of a transverse transmission shaft tube 3 installed inside the outer shell 1, an internal adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com