Burnt chili oil and preparation method thereof as well as essence containing burnt chili oil and preparation method of essence

A technology for paste pepper and pepper oil, which is applied to paste pepper oil and its preparation, the essence of paste pepper oil and its preparation field, can solve the problems of reduced nutritional value of paste pepper, loss of nutrients of dried pepper and the like, and achieves the effect of enriching taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

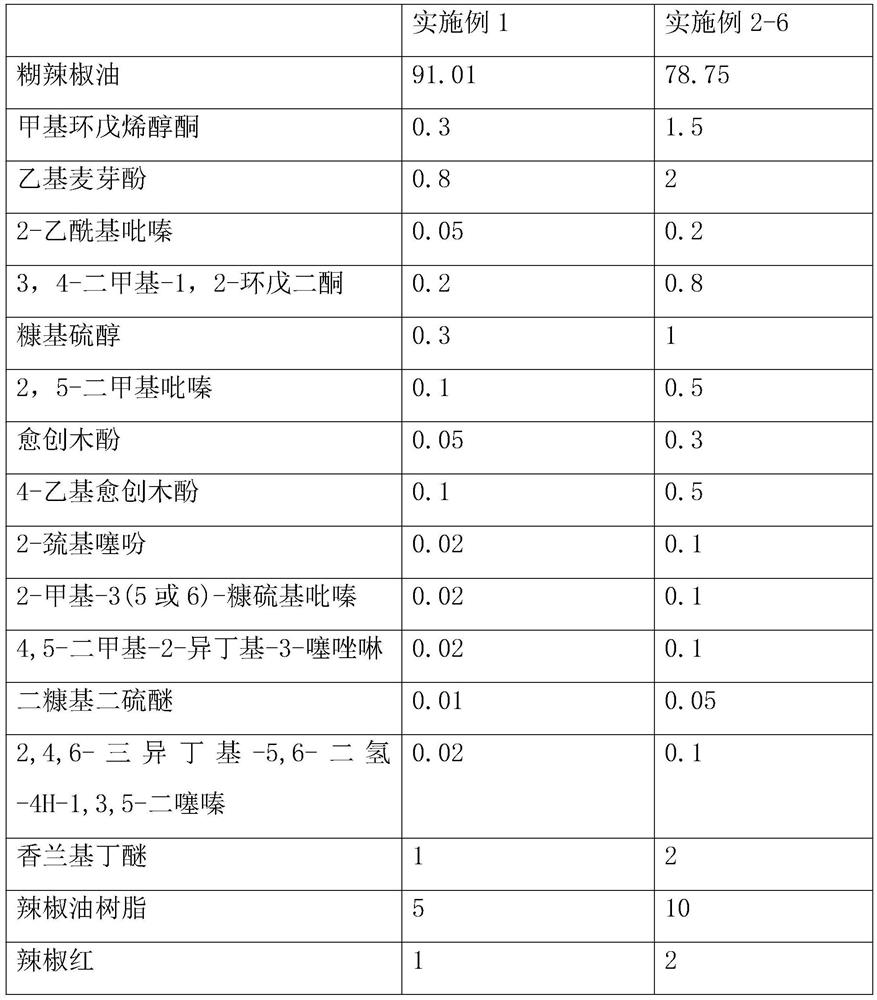

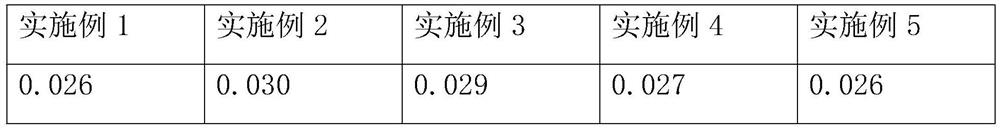

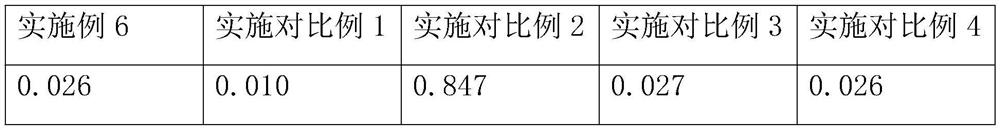

Examples

preparation example 1

[0064] A preparation method of paste chili oil, comprising the following steps:

[0065] Step 1, heating up and frying: put 15kg of devil’s chili powder and 95kg of soybean salad oil into a stirring tank, stir and heat up to 158°C at a rotation speed of 40r / min, keep it warm for 25min, and obtain a preliminary extract.

[0066] Step 2, Soaking and Extracting: Turn on the cooling water, lower the temperature of the preliminary extract to 40°C, transfer the preliminary extract to the leaching tank, keep it soaked for 60 hours, and then transfer the soaked preliminary extract to the centrifuge , centrifuge and filter at a speed of 4000r / min, and take the oil phase to obtain paste chili oil.

preparation example 2

[0068] A preparation method of paste chili oil, comprising the following steps:

[0069] Step 1, heating up and frying: Put 20kg of devil’s chili powder and 105kg of soybean salad oil into a stirring tank, stir and heat up to 167°C at a rotation speed of 50r / min, keep it warm for 20min, and obtain a preliminary extract.

[0070] Step 2, soaking and extraction: turn on the cooling water, lower the temperature of the preliminary extract to 50°C, transfer the preliminary extract to the leaching tank, keep it soaked for 40 hours, and then transfer the soaked preliminary extract to the centrifuge , centrifuge and filter at a speed of 5000r / min, and take the oil phase to obtain paste chili oil.

preparation example 3

[0072] A preparation method of paste chili oil, the only difference from Example 1 is that in step 1, an equal amount of dried chili powder is used to replace devil chili powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com