Ceramic chip surface wiper

A wiper and tile technology, which is applied in the direction of cleaning carpets, floors, household appliances, etc., can solve problems such as back pain, reduce tile wiping efficiency, etc., and achieve the effect of improving wiping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

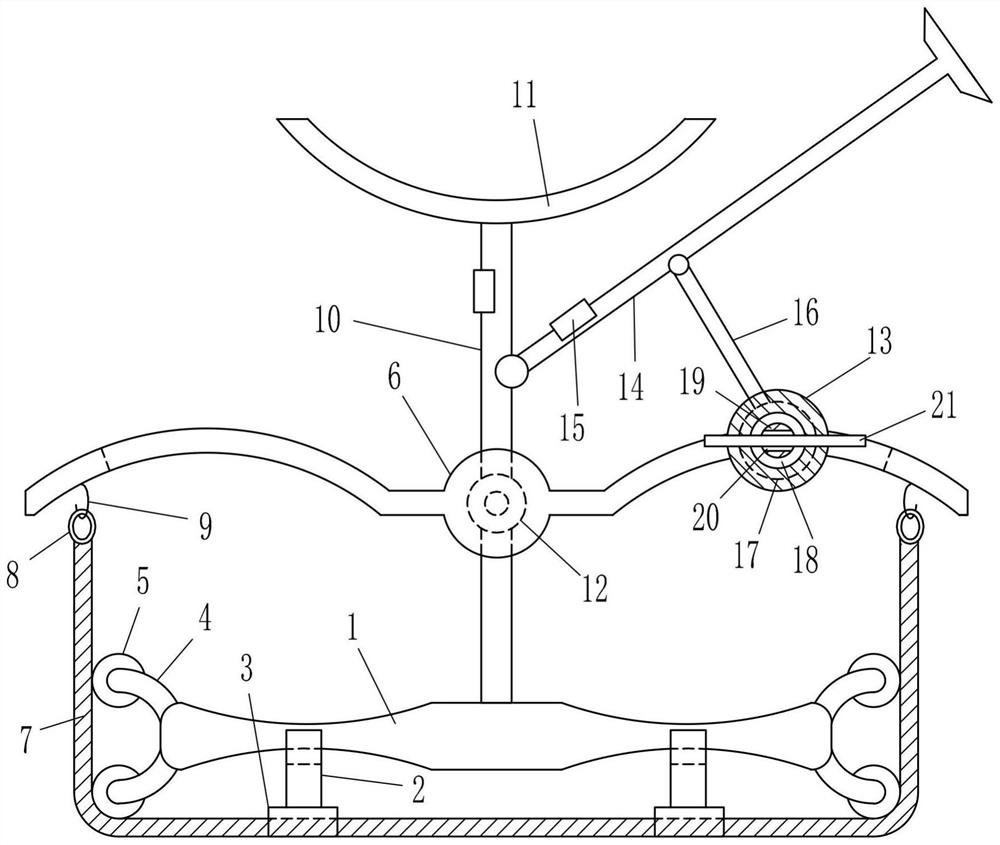

[0016] A tile surface wiper, such as Figure 1-2 As shown, it includes a support plate 1, a support rod 2, a support block 3, an arc rod 4, a contact wheel 5, a swing frame 6, a cleaning cloth 7, a ring buckle 8, a hook 9, a pole 10, and an arc handle 11 With mounting column 12, the front, rear, left, and right sides of support plate 1 are all connected with support bar 2, the bottom end of support bar 2 is connected with support block 3, and the front, rear, left, right, four sides of support plate 1 are all connected with arc bar 4, arc-shaped The upper and lower ends of the rod 4 are rotatably connected with contact wheels 5, the middle of the top of the support plate 1 is connected with a pole 10, the top of the pole 10 is connected with an arc-shaped lifting rod 11, and the lower parts of the front and rear sides of the pole 10 are connected There are mounting columns 12, and a swinging frame 6 is rotatably connected between the two mounting columns 12. The two mounting c...

Embodiment 2

[0018] A tile surface wiper, such as Figure 1-2 As shown, it includes a support plate 1, a support rod 2, a support block 3, an arc rod 4, a contact wheel 5, a swing frame 6, a cleaning cloth 7, a ring buckle 8, a hook 9, a pole 10, and an arc handle 11 With mounting column 12, the front, rear, left, and right sides of support plate 1 are all connected with support bar 2, the bottom end of support bar 2 is connected with support block 3, and the front, rear, left, right, four sides of support plate 1 are all connected with arc bar 4, arc-shaped The upper and lower ends of the rod 4 are rotatably connected with contact wheels 5, the middle of the top of the support plate 1 is connected with a pole 10, the top of the pole 10 is connected with an arc-shaped lifting rod 11, and the lower parts of the front and rear sides of the pole 10 are connected There are mounting columns 12, and a swinging frame 6 is rotatably connected between the two mounting columns 12. The two mounting c...

Embodiment 3

[0021] A tile surface wiper, such as Figure 1-2 As shown, it includes a support plate 1, a support rod 2, a support block 3, an arc rod 4, a contact wheel 5, a swing frame 6, a cleaning cloth 7, a ring buckle 8, a hook 9, a pole 10, and an arc handle 11 With mounting column 12, the front, rear, left, and right sides of support plate 1 are all connected with support bar 2, the bottom end of support bar 2 is connected with support block 3, and the front, rear, left, right, four sides of support plate 1 are all connected with arc bar 4, arc-shaped The upper and lower ends of the rod 4 are rotatably connected with contact wheels 5, the middle of the top of the support plate 1 is connected with a pole 10, the top of the pole 10 is connected with an arc-shaped lifting rod 11, and the lower parts of the front and rear sides of the pole 10 are connected There are mounting columns 12, and a swinging frame 6 is rotatably connected between the two mounting columns 12. The two mounting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com