A kind of clindamycin phosphate injection preparation and preparation method thereof

A technology for clindamycin phosphate and injection, which is applied in the field of pharmaceutical inventions, can solve the problems of inability to use intramuscular injection for children, low production efficiency, insufficient nitrogen filling in production, etc., so as to improve the dispensing efficiency and the stability of the medicinal solution. , good pH value, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

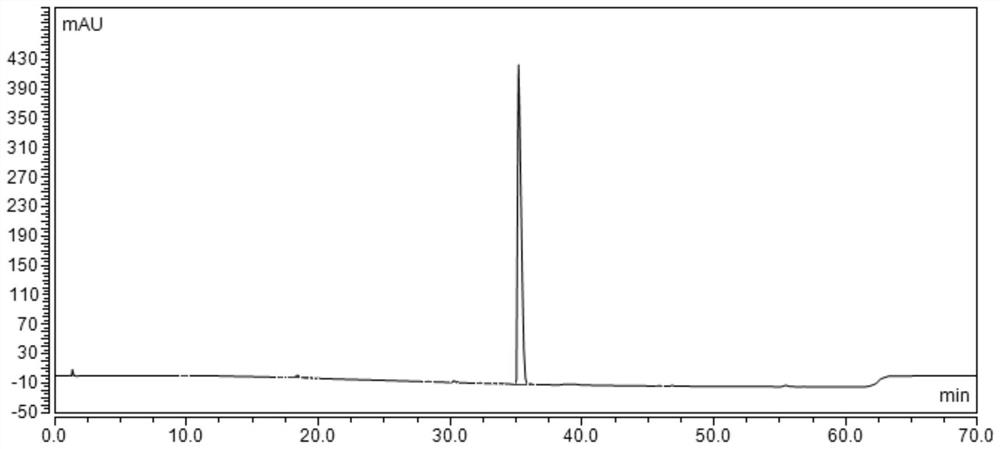

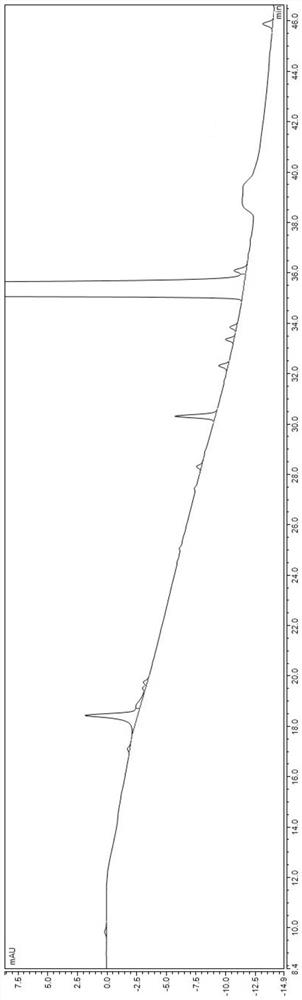

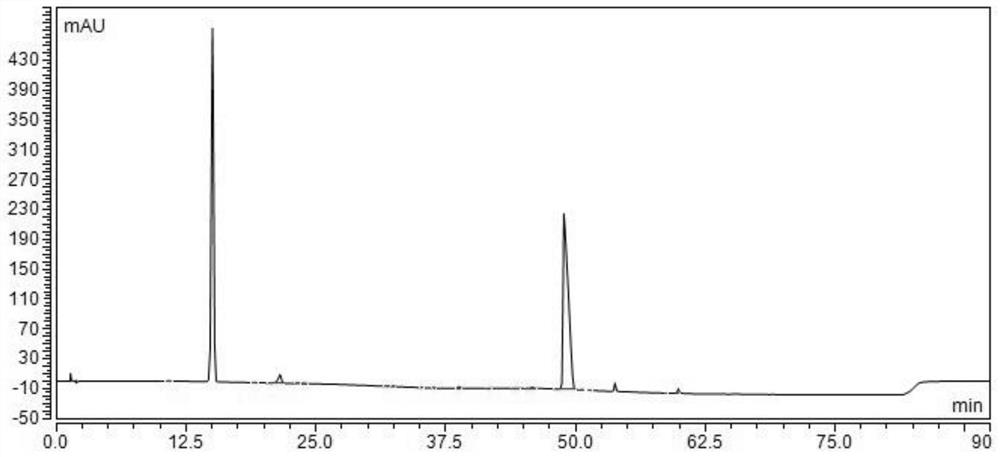

Image

Examples

Embodiment 1

[0048] A clindamycin phosphate injection preparation, in every 1000ml injection, comprising:

[0049] Clindamycin Phosphate 130g, Thioglycerol 0.3g, Sodium Hydroxide 8g.

[0050] The preparation method of described clindamycin phosphate injection preparation, comprises the following steps:

[0051] (1) Get sodium hydroxide and dissolve it with 30°C water for injection to prepare a 10% sodium hydroxide solution;

[0052] (2) Add water for injection at 10°C in the liquid mixing tank, add thioglycerol, stir at 100 rpm for 40 minutes until completely dissolved, and make a thioglycerol solution;

[0053] (3) Get clindamycin phosphate and 10% sodium hydroxide solution and add them to the thioglycerol solution in 8 times;

[0054] (4) Dilute to 1000ml with water for injection, stir until the solution is evenly mixed, check the pH value, first filter once through a filter membrane with a pore size of 0.45 μm, and then filter twice through a filter membrane with a pore size of 0.22 μ...

Embodiment 2

[0059] A clindamycin phosphate injection preparation, in every 1000ml injection, comprising:

[0060] Clindamycin Phosphate 170g, Thioglycerol 0.8g, Sodium Hydroxide 16g.

[0061] The preparation method of described clindamycin phosphate injection preparation, comprises the following steps:

[0062] (1) Get sodium hydroxide and dissolve it with water for injection at 10°C to prepare a 10% sodium hydroxide solution;

[0063] (2) Add water for injection at 30°C into the liquid mixing tank, add thioglycerol, stir at 150 rpm for 30 minutes until completely dissolved, and make a thioglycerol solution;

[0064] (3) Get clindamycin phosphate and 10% sodium hydroxide solution and add them to the thioglycerol solution in 8 times;

[0065] (4) Dilute to 1000ml with water for injection, stir until the solution is evenly mixed, check the pH value, first filter once through a filter membrane with a pore size of 0.45 μm, and then filter twice through a filter membrane with a pore size of ...

Embodiment 3

[0070] A clindamycin phosphate injection preparation, in every 1000ml injection, comprising:

[0071] Clindamycin Phosphate 150g, Thioglycerol 0.5g, Sodium Hydroxide 12g.

[0072] The preparation method of described clindamycin phosphate injection preparation, comprises the following steps:

[0073] (1) Get sodium hydroxide, dissolve and be mixed with the sodium hydroxide solution that concentration is 10% with the water for injection of 20 ℃;

[0074] (2) Add water for injection at 20°C into the liquid mixing tank, add thioglycerol, stir at 150 rpm for 60 minutes until completely dissolved, and make a thioglycerol solution;

[0075] (3) Get clindamycin phosphate and 10% sodium hydroxide solution and add them to the thioglycerol solution in 8 times;

[0076] (4) Dilute to 1000ml with water for injection, stir until the solution is evenly mixed, check the pH value, first filter once through a filter membrane with a pore size of 0.45 μm, and then filter twice through a filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com