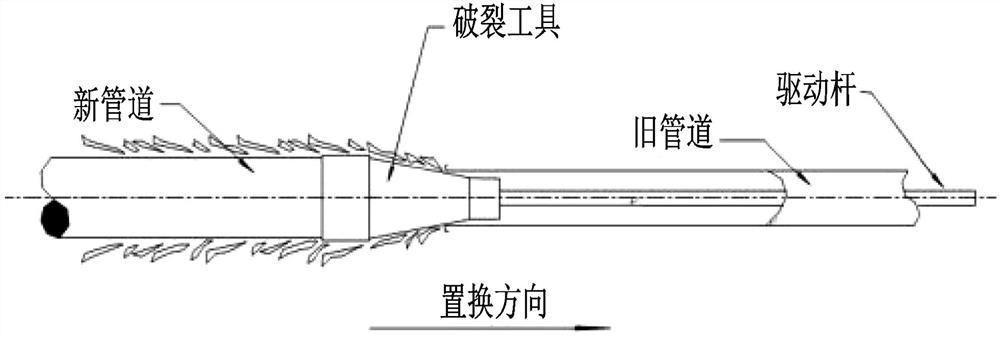

Flexible and rigid pipe universal crushing head and method for pipe explosion method construction

A crushing head, rigid technology, applied in the field of crushing head of split pipe construction, can solve the problems of increasing excavation, increasing repair costs, direct connection, etc., to achieve the effect of improving work efficiency and reducing the amount of repair construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0052] A method for split pipe construction by the broken head of the general split pipe construction method for flexible and rigid pipes, comprising the following steps:

[0053] When the rigid pipe and the flexible pipe are directly connected between two inspection wells and split pipe construction is required, the construction method is as follows:

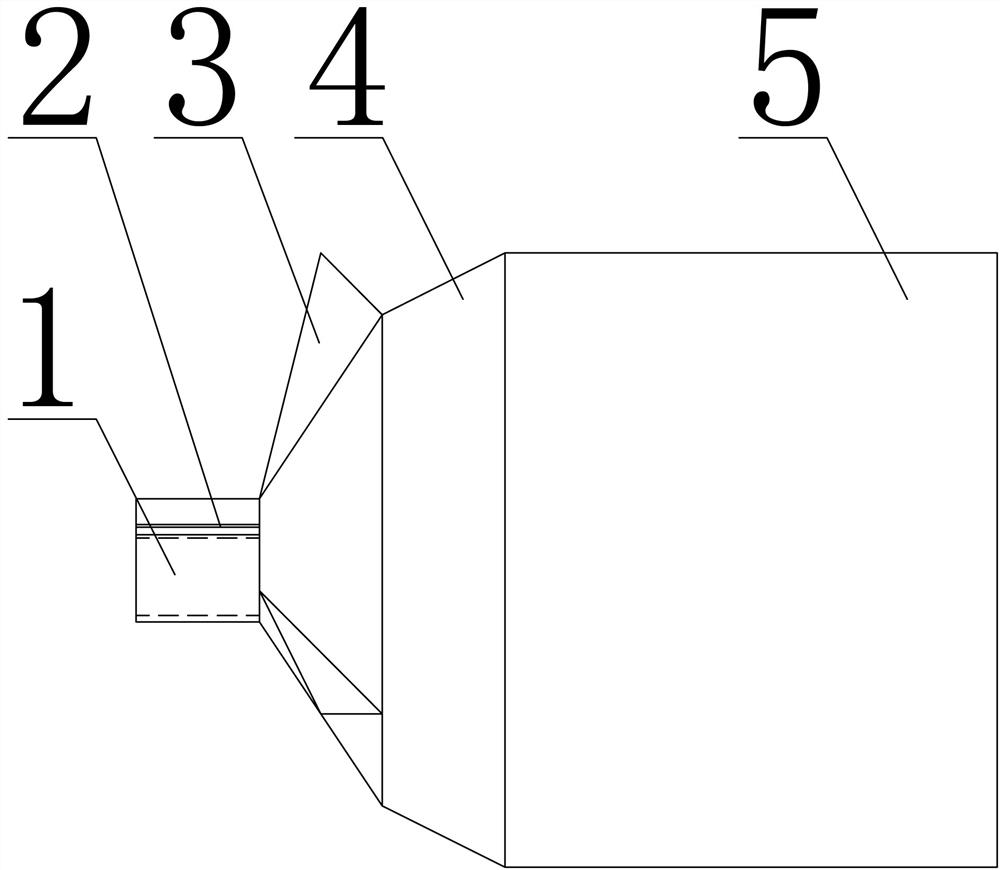

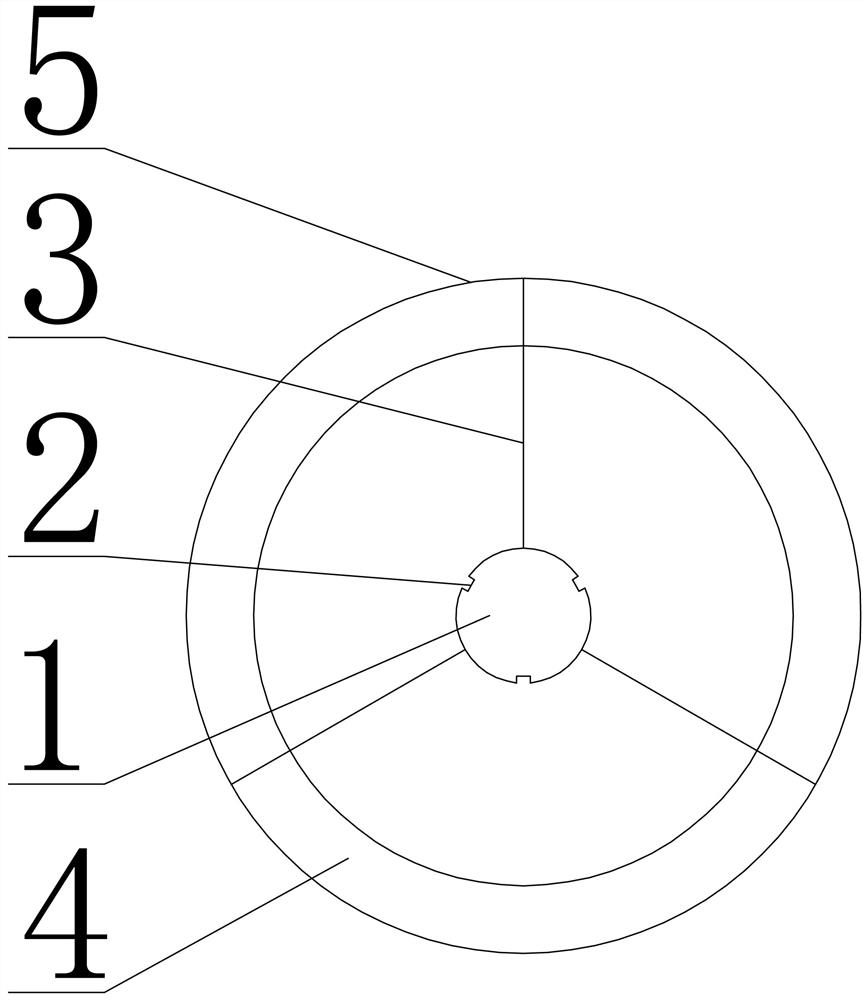

[0054] Step 1: Thread the drive rod 24 between the two inspection wells to be repaired for the cracked pipe, and thread the main rope 23 into the drive rod 24 synchronously. One end of the main rope 23 is located in the receiving well of the cracked pipe, and the other end is connected to the elastic unlocking member The open ends of 20 are connected;

[0055] Step 2: Install the assembled casing 14 and elastic unlocking part 20 step by step in the working well, put the protective cover structure 6 on the outside of the casing 14, and pass the crossbar at the reserved hole 10 of the protective cover structure 6 11, connect the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap