Marble scrap screening sieve plate

A crushed material sieve and marble technology, applied in the field of marble crushed material screening sieve plate, can solve problems such as defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

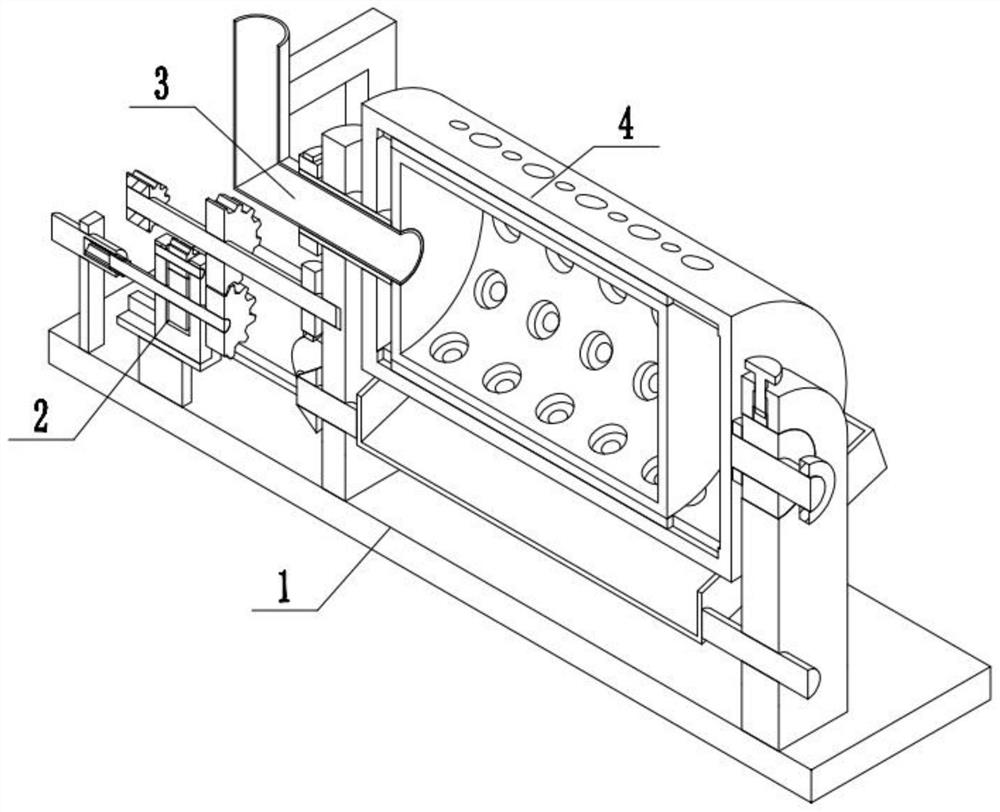

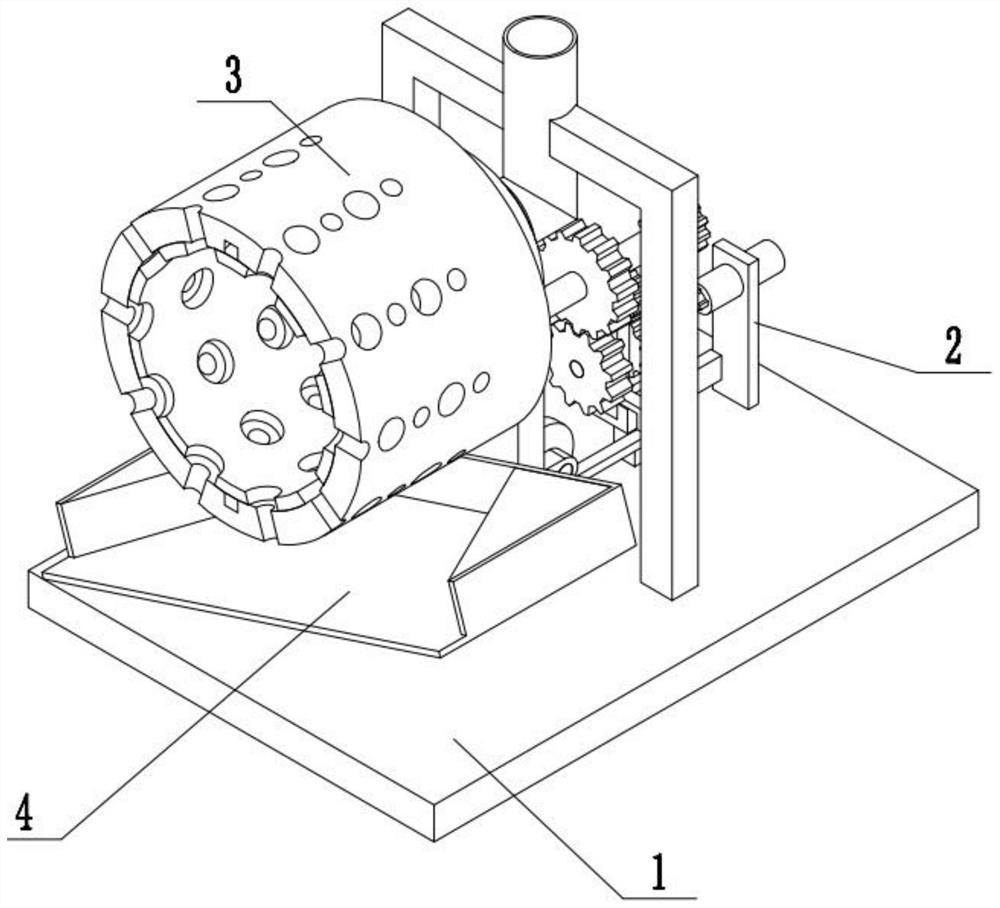

[0027] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 illustrate this embodiment, and this embodiment will further explain Embodiment 1. In order to solve the above technical problems, a marble crushing screening sieve plate , including installing a fixed plate 1, a power transmission control device 2, a screening device 3, and a material discharge device 4, and installing other devices through the installation of a fixed plate, the power transmission control device provides power for screening and changes the mode of screening and crushing The material discharge mode, the screening device screens the crushed material and there are two types of screening, the material distribution discharge device controls the discharge of the crushed material according to the screening form, and other functions. It is characterized in that: power transmission control device 2 Installed and fixed on the installation fixed plate 1, the screening device 3 is installed and fixed on...

specific Embodiment approach 2

[0029] Combine below figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 describe this embodiment, and this embodiment will further describe Embodiment 1. The described power transmission control device 2 includes a fixed mounting plate 2-1 , active input cross hole shaft 2-2, fixed sliding seat 2-3, sliding groove 2-4, pulling groove 2-5, screening mode 1 control groove 2-6, screening mode 2 control groove 2-7, sliding Mounting seat 2-8, control limit bolt 2-9, transmission shaft 2-10, cross connection bar 2-11, gear one 2-12, gear two 2-13, fixed shaft 2-14, transmission gear 2-15 , limit sliding groove 2-16, the crushed material processed by the crushing device enters the internal rotating cylinder 3-11 through the feeding cylinder 3-2, and then drives the control limit bolt 2-9 of the power transmission control device 2 The sliding installation seat 2-8 slides inside the sliding groove 2-4 of the fixed sliding seat 2-3 to the upper end of the screening mode one control gro...

specific Embodiment approach 3

[0031] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The described screening device 3 includes a mounting bracket 3-1, Feed cylinder 3-2, support mounting plate 3-3, transmission cylinder 3-4, transmission pulley 3-5, transmission belt 3-6, transmission shaft two 3-7, receiving gear one 3-8, receiving gear two 3 -9, output pulley 3-10, internal rotating cylinder 3-11, discharge hole 3-12, sliding column 3-13, rotating internal threaded ring 3-14, moving threaded column 3-15, limit stop ring 3- 16. Friction block 3-17, control thread bolt 3-18, screening cylinder 2 3-19, discharge hole 1 3-20, discharge hole 2 3-21, matching sliding groove 3-22, drive shaft 2-10 Drive the receiving gear 2 3-9 to rotate through the gear 2 2-13, the receiving gear 2 3-9 drives the output pulley 3-10 to rotate through the transmission shaft 2 3-7, and the output pulley 3-10 is driven by the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com