Numerical control turning method for multi-line trapezoidal threads

A trapezoidal thread and turning technology, which is applied in the field of trapezoidal thread processing, can solve the problems of sharpening, increased cutting force and cutting heat, and difficulty in chip removal during processing, and achieve the effect of avoiding random threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

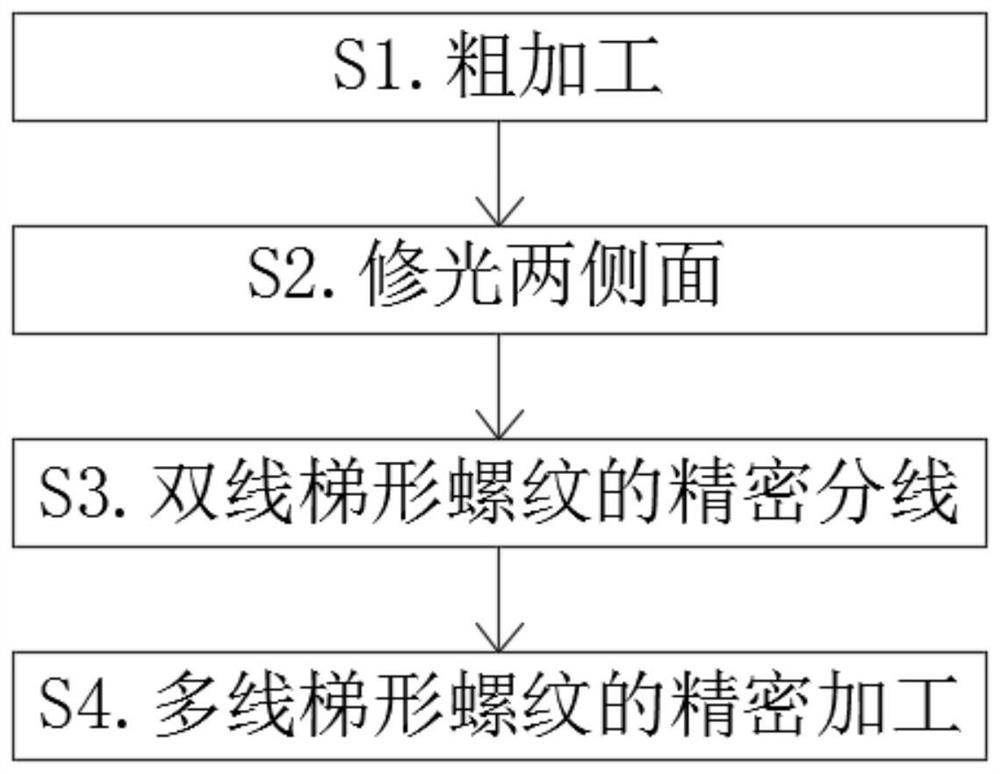

[0043] Such as Figure 1 ~ Figure 3 As shown, the embodiment of the present invention provides a kind of numerical control turning method of multi-line trapezoidal screw thread, comprises the following steps:

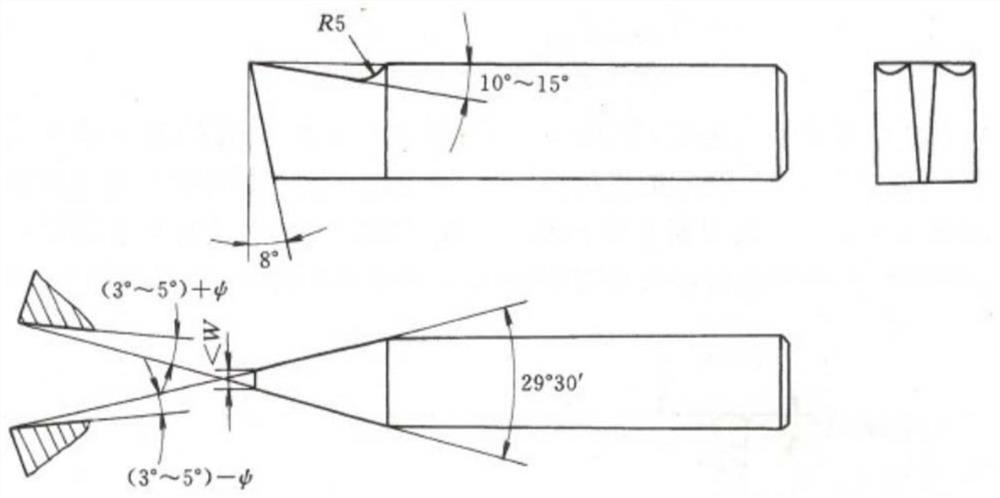

[0044] S1. Rough machining: programming with G76 command, rough machining with thread rough turning tool;

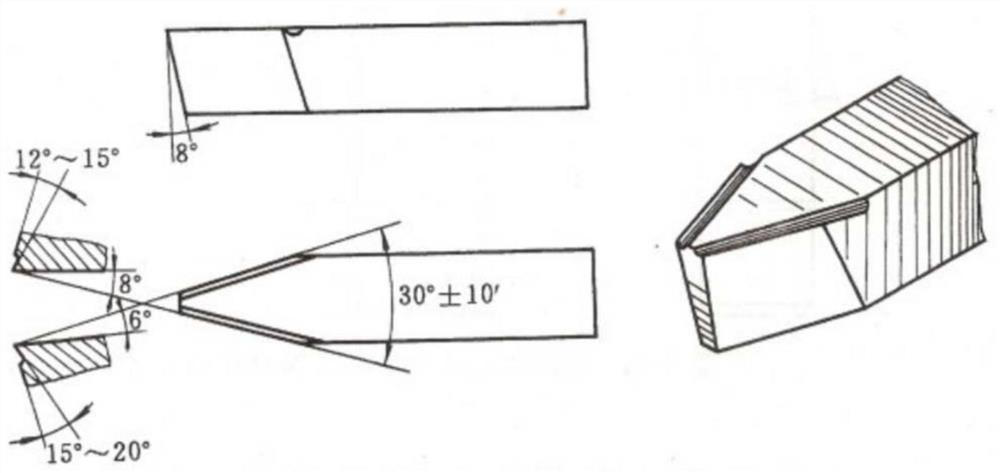

[0045] S2. Smoothing both sides: Change the thread finishing tool to smooth both sides of the trapezoidal thread, and the processing process of smoothing the two sides is: respectively compile two subroutines, and make the z-direction offset of the turning tool by 0.1 each time it is called mm, measure the trapezoidal thread after rough machining by the three-needle measurement method, read the actual measured value M actual measurement of the distance M between the vertices of the two measuring needles of the common normal micrometer, calculate the theoretical value M of the distance, and further calculate the actual measurement and M Theoretical difference, to ...

Embodiment 2

[0061] Such as Figure 1 ~ Figure 3 As shown, the embodiment of the present invention provides a kind of numerical control turning method of multi-line trapezoidal screw thread, comprises the following steps:

[0062] S1. Rough machining: programming with G76 command, rough machining with thread rough turning tool;

[0063] S2. Smoothing both sides: Change the thread finishing tool to smooth both sides of the trapezoidal thread, and the processing process of smoothing the two sides is: respectively compile two subroutines, and make the z-direction offset of the turning tool by 0.1 each time it is called mm, measure the trapezoidal thread after rough machining by the three-needle measurement method, read the actual measured value M actual measurement of the distance M between the vertices of the two measuring needles of the common normal micrometer, calculate the theoretical value M of the distance, and further calculate the actual measurement and M Theoretical difference, to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com