Five-axis linkage milling and turning combined machining system and working method

A compound processing and five-axis linkage technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as single processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

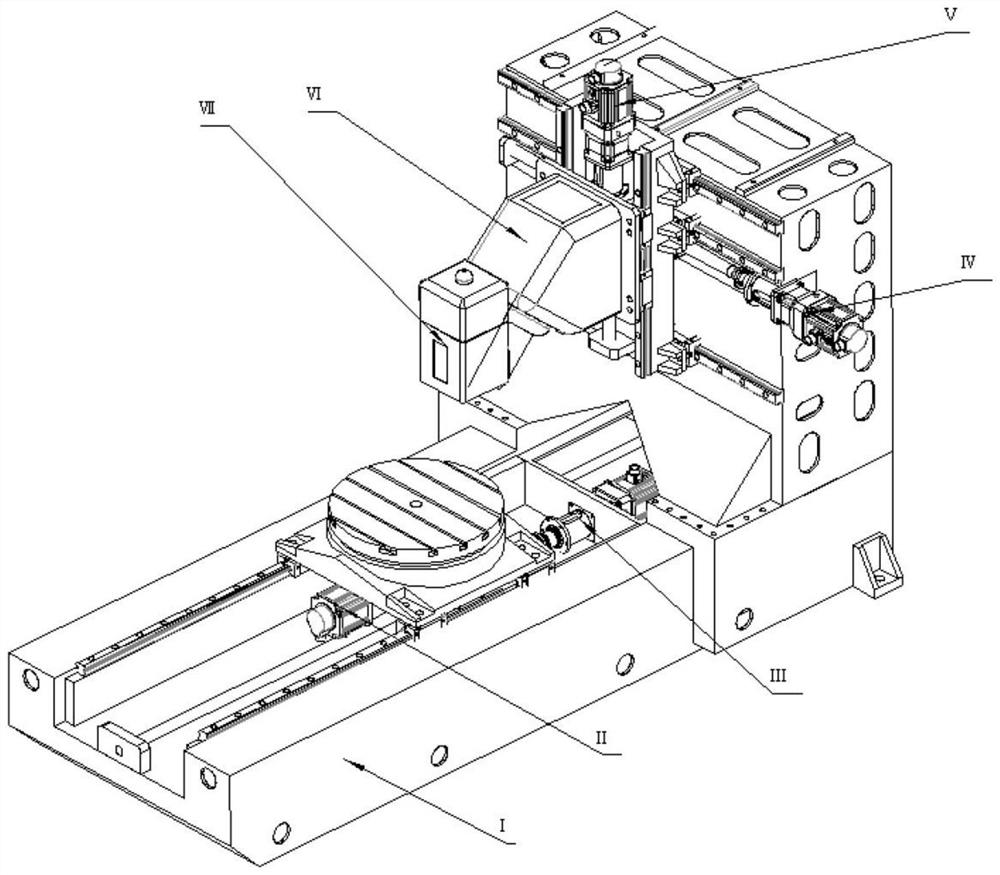

[0025] Such as Figure 1-7 As shown, this five-axis milling-turning compound processing system includes the main engine base I, the CNC rotary table II, the X-axis drive system III, the Y-axis drive system IV, the Z-axis drive system V, and the fifth-axis drive system VI , Tool mounting seat VII;

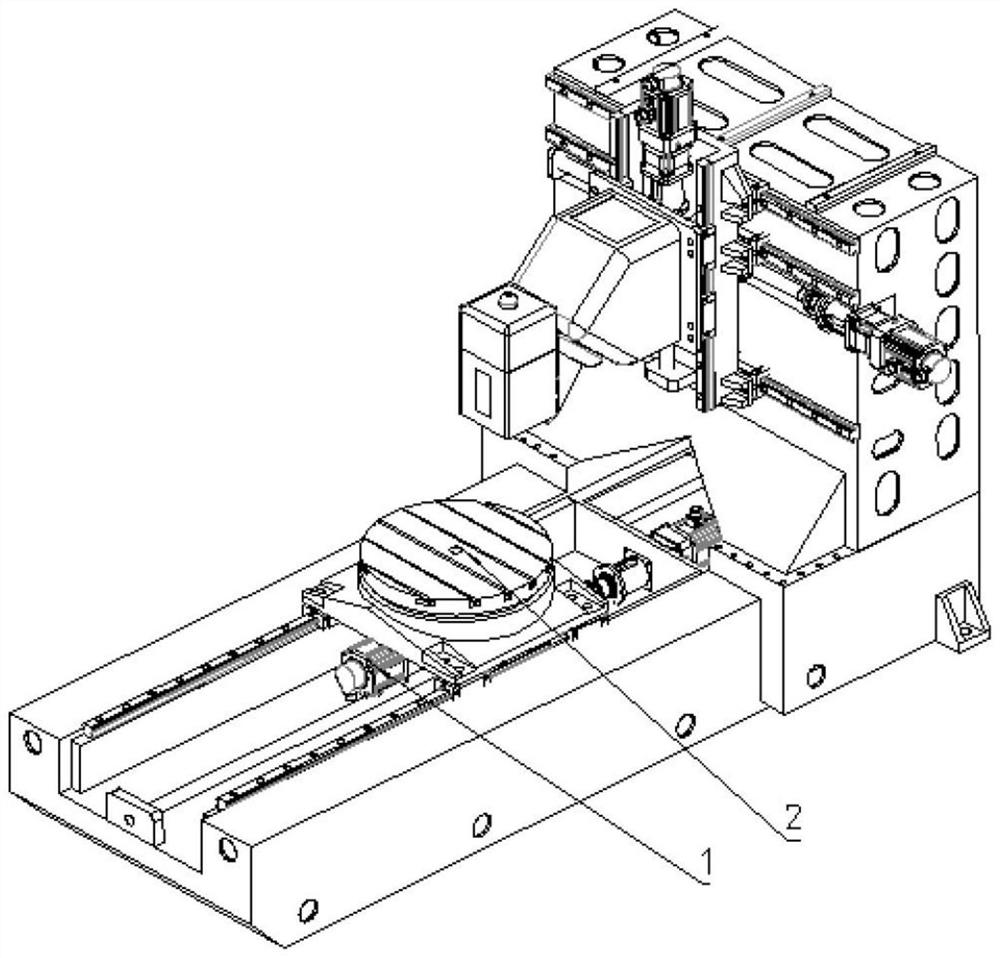

[0026] CNC rotary workbench II includes DD direct drive motor 1 and workbench 2. Driven by DD direct drive motor 1, workbench 2 can rotate around the center of workbench 2, which is the first axis;

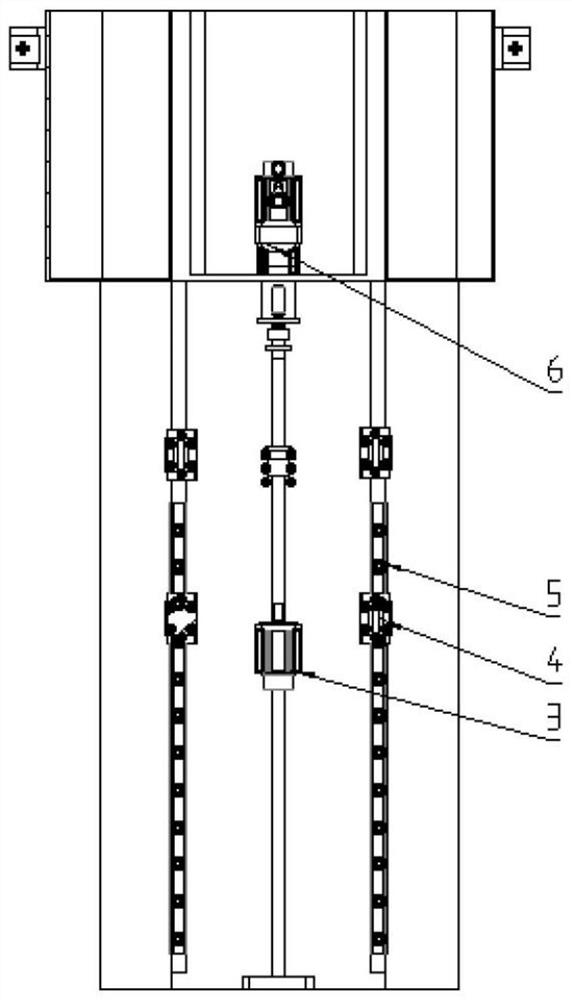

[0027] The CNC rotary table II is fixed on the first slider 4 and the first drive block 3 of the X-axis drive system III, and the first motor 6 drives the drive block 3 to drive the CNC rotary table II to reciprocate along the direction of the first guide rail 5 Movement, this is the second axis;

[0028] The frame A 14 is fixed on the second slider 7 and the second drive block 10 of the Y-axis drive system IV, and the second motor 9 drives the second drive block 10 to drive the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com