Automatic feeding device for numerical control cutting equipment

A technology of cutting equipment and material receiving device, which is applied in metal processing and other directions, can solve the problems of low material receiving efficiency, low integration, and inability to adjust, and achieve the effects of high efficiency and accuracy, high material receiving efficiency, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

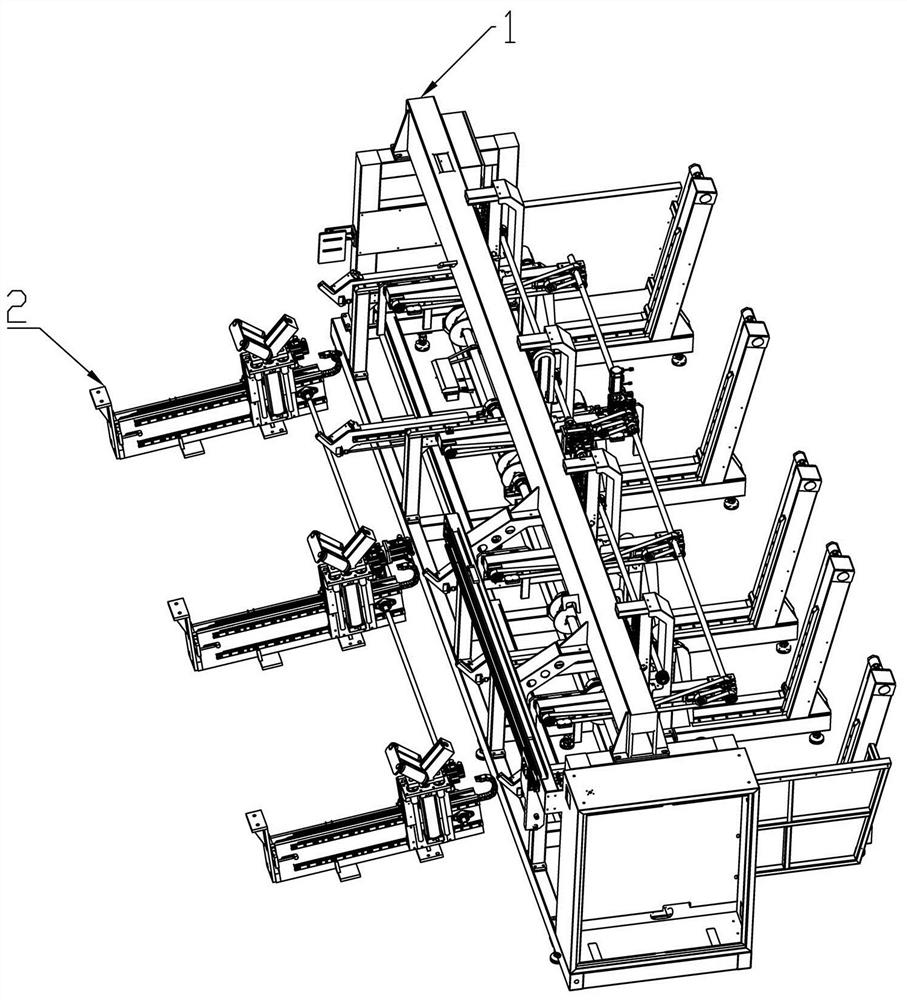

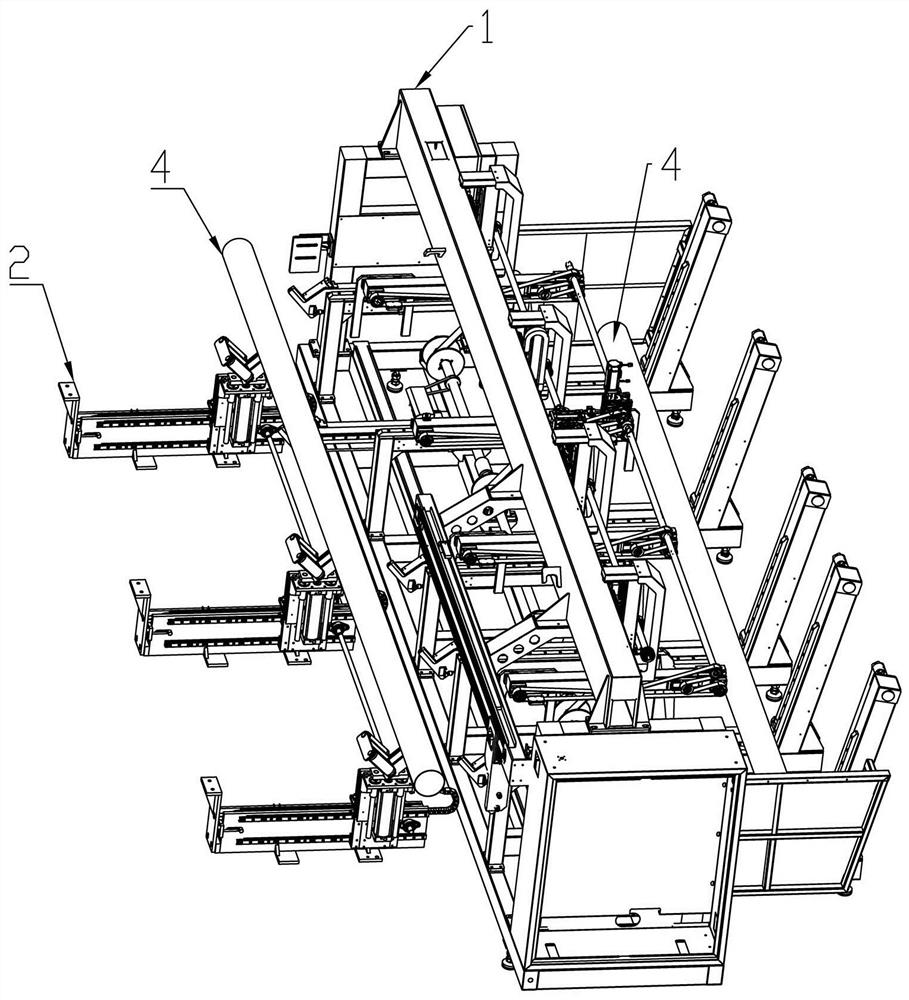

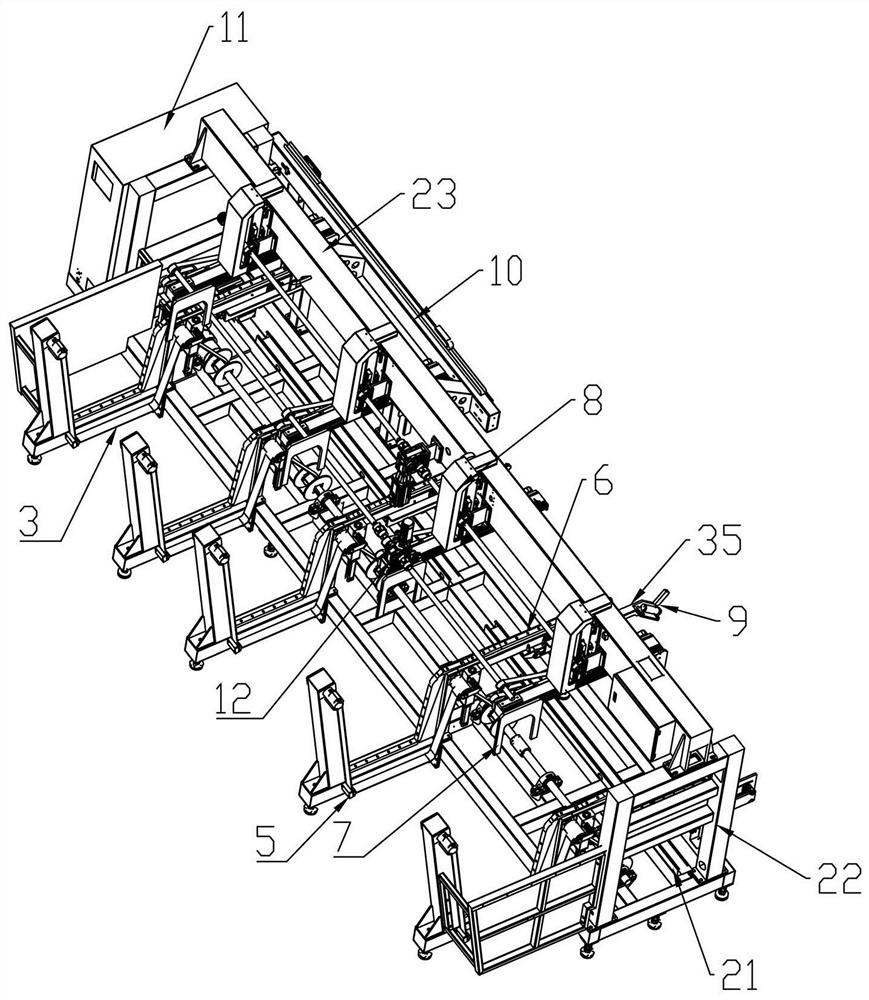

[0051] See attached figure 1 , 2 , 3, 4, and 5, an automatic feeding device for CNC cutting equipment, including a feeding device 1 and a receiving device 2, the feeding device 1 includes a groove-shaped silo 3, extending to the groove The bottom of the silo 3 and the first conveying unit 5 that outputs the pipe 4 upwards through the conveyor belt mechanism, the second conveying unit 6 docked with the upper part of the first conveying unit 5, the paddle 7 arranged above the second conveying unit 6, The height adjustment unit 8 that adjusts the distance between the paddle 7 and the second conveying unit 6, the receiving unit 9 that accepts the pipe 4 on the second conveying unit 6, and the end of the pipe 4 in the receiving unit 9 are positioned and measured. The positioning and length measuring unit 10 of the length and the control unit 11 controlling the automatic feeding device, the groove type feed bin 3, the first conveying unit 5, and the second conveying unit 6 are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com