Downward-moving type tight die capable of implementing overall rapid movement-out of part

A fast and integrated technology, applied in the field of molds, can solve the problems of damage to molded products, poor versatility, affecting the qualified rate of product injection, and achieve the effect of avoiding damage and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

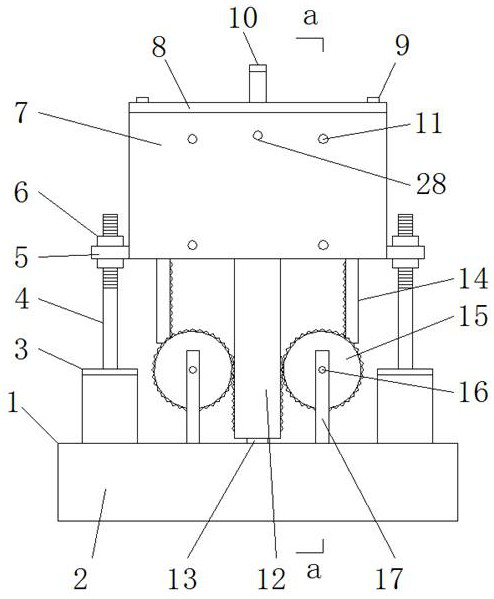

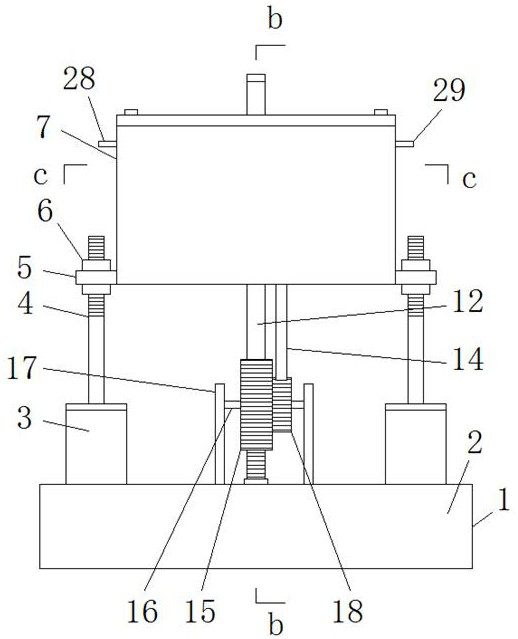

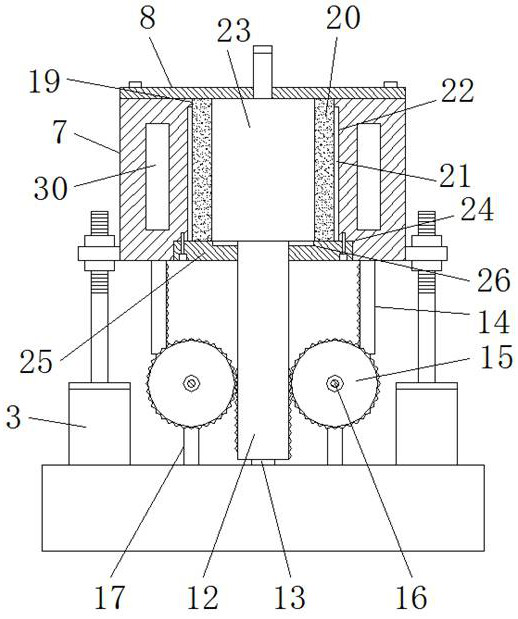

[0027] see Figure 1-7, the present invention provides a technical solution: a down-moving compact mold that can realize the rapid removal of parts as a whole, including a mold mounting frame 1, a base 2, a telescopic mechanism 3, a support rod 4, a connecting plate 5, an adjusting nut 6, an outer Die body 7, sealing top plate 8, fastening bolt 9, pouring pipe 10, limit bolt 11, lifting rod 12, touch switch 13, lower pressing rod 14, external gear plate 15, rotating shaft 16, support frame 17, Inner gear plate 18, installation chamber 19, inner mold body 20, limit slide bar 21, limit groove 22, inner mold cavity 23, installation groove 24, sealing bottom plate 25, storage groove 26, support template 27, water inlet pipe 28, Outlet pipe 29 and cooling chamber 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com