Device for preventing inclined crack of web in anchoring area at end part of prestressed small box girder

A technology of end anchorage and small box girders, which is applied to bridges, bridge parts, bridge materials, etc., can solve problems such as cracking and complex stress states in the anchorage area at the end of box girders, and achieve convenient construction, good application value, and economic benefits significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

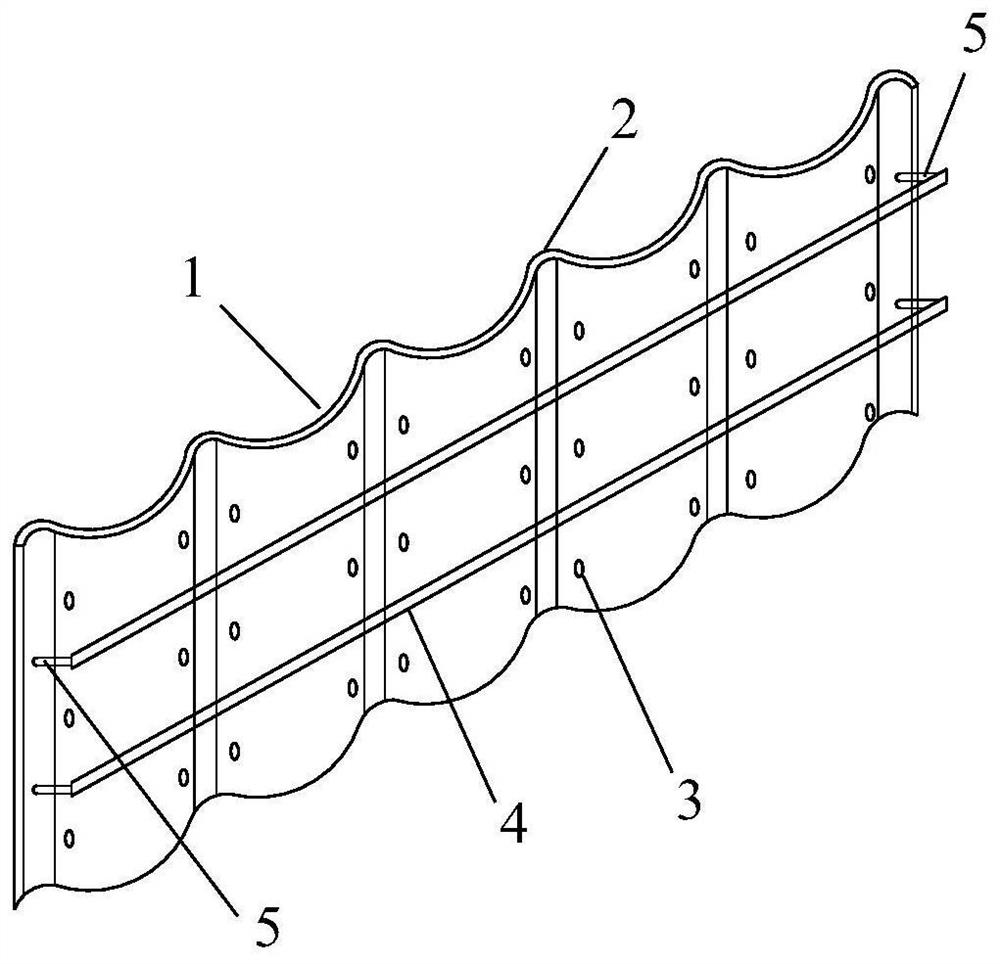

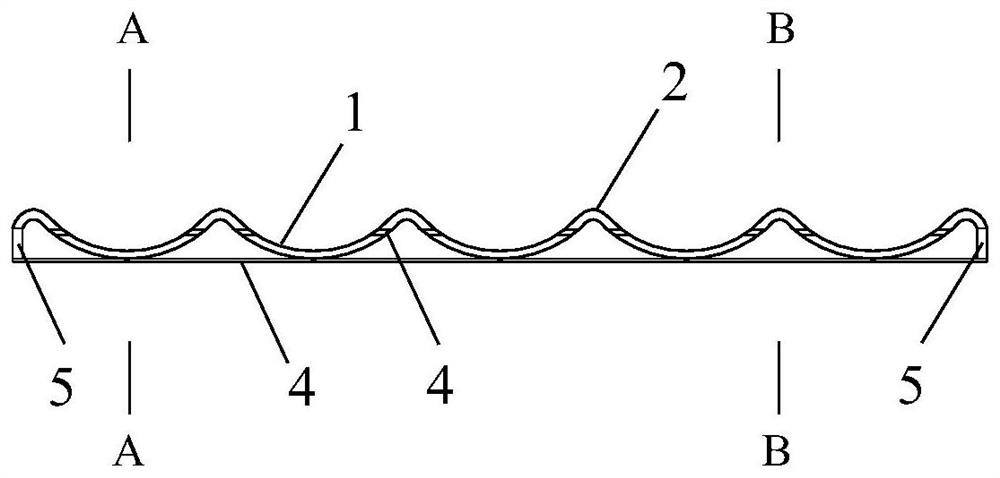

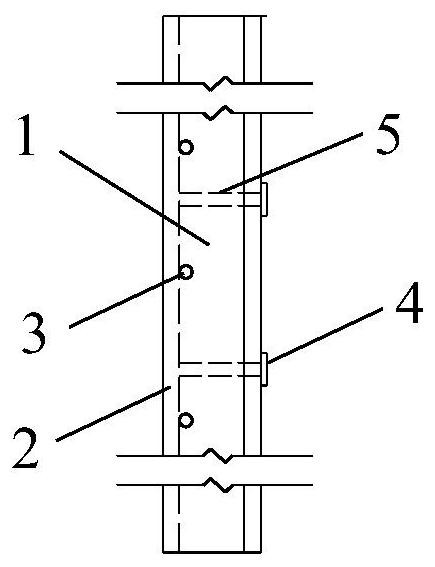

[0031] The present invention is a device used to prevent oblique cracks in the web plate of the anchorage area at the end of a prestressed small box girder. Its structure is as follows Figure 1-4 As shown, it includes a plurality of semi-annular casings 2 arranged side by side in sequence, and a flat arch plate 1 is arranged between two adjacent semi-annular casings 2, and the arc openings of the flat arch plate 1 and the semi-annular casing 2 are opposite. , the arch surfaces of a plurality of flat arch plates 1 are jointly fixed with transverse support plates 4, the two ends of the transverse support plates 4 are fixedly connected with transverse connecting rods 5, and the other ends of the two transverse connecting rods 5 are respectively fixed on the first and last On a semi-annular casing 2, each flat arch plate 1 is provided with a cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com