Oblique steel support concrete shear wall composite coupling beams and production method thereof

A concrete shear wall and shear wall technology, applied in the direction of walls, structural elements, building components, etc., can solve problems such as large internal force of coupling beams, achieve the effects of improving shear stiffness, preventing collapse, and improving overall seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

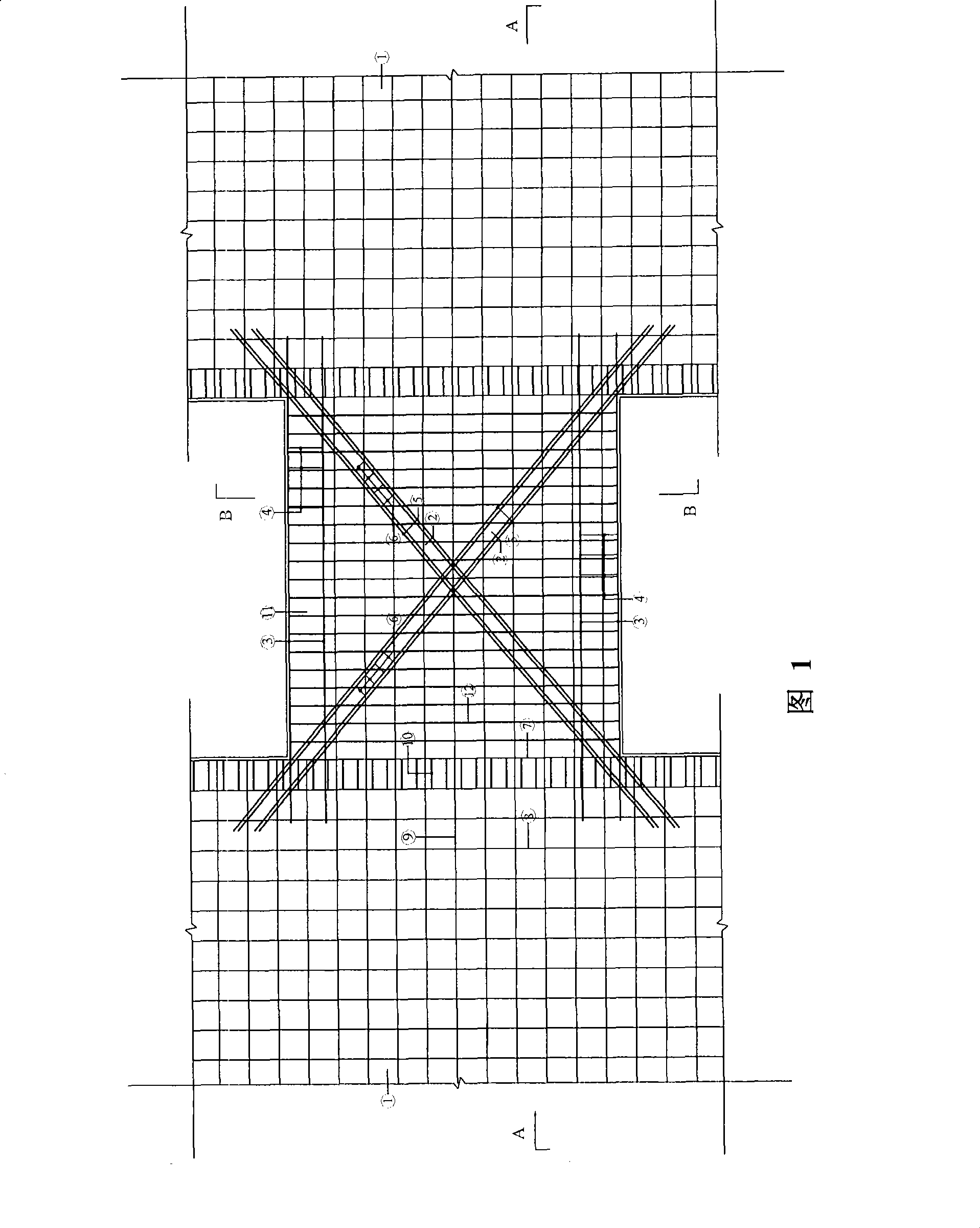

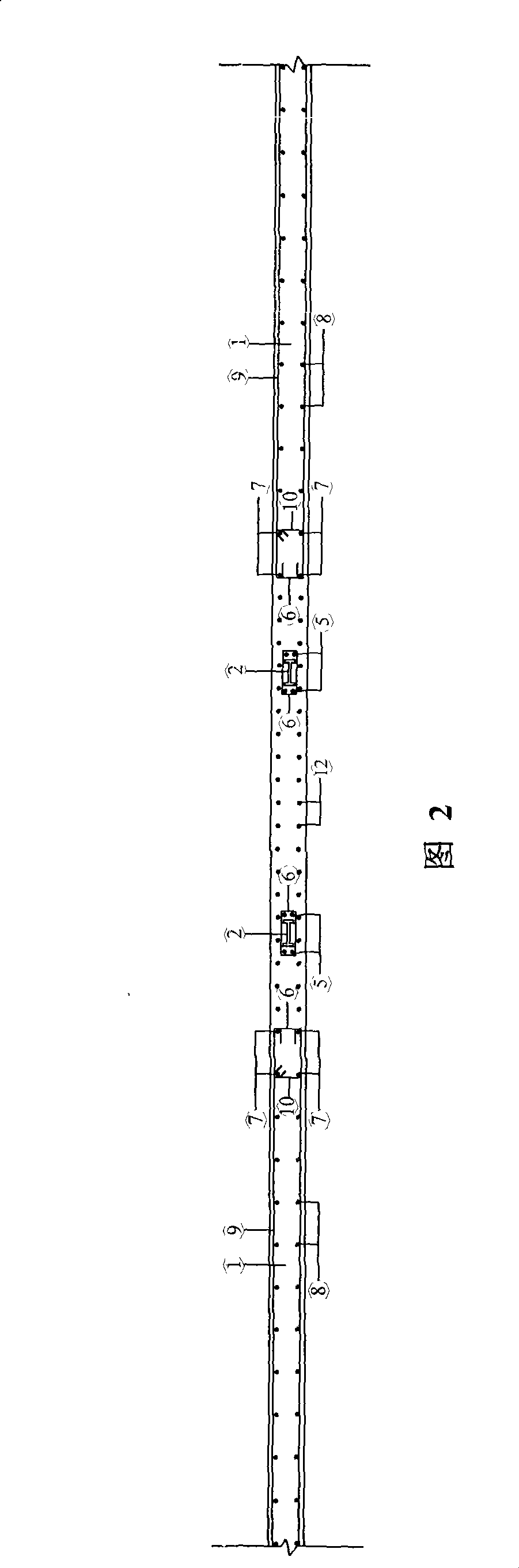

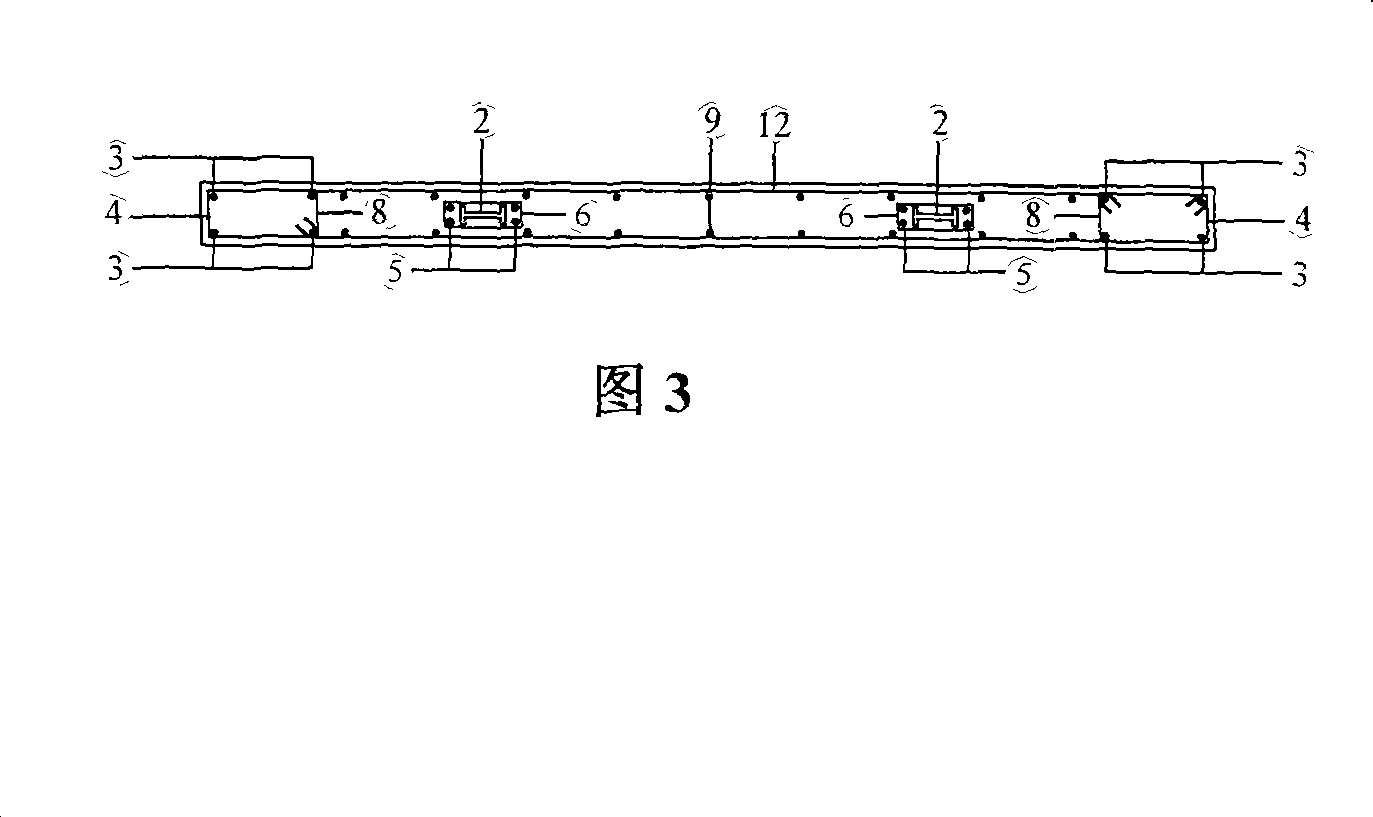

[0025] Below in conjunction with accompanying drawing 1~accompanying drawing 3 the embodiment of the present invention is described in further detail:

[0026] The schematic diagram of the structural reinforcement of a structural unit of the composite coupling beam of the concrete shear wall supported by inclined steel is shown in Fig. 1, Fig. 2 and Fig. 3. The inclined steel support 2 inside the reinforcement support 5 is composed of concrete composite connecting beams. The reinforcement of the shear wall body 1 is the longitudinal steel bar 8 and the horizontal steel bar 9, and the end of the wall close to the connecting beam is provided with a concealed column, and the concealed column is equipped with a concealed column longitudinal steel bar 7 and bound on the outside of the concealed column longitudinal steel bar 7 10 of hidden column rectangular stirrups.

[0027] As shown in Figure 1, frame beams 11 are arranged on the upper and lower parts of the connecting beams. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com