Prefabricated steel-encased concrete column and concrete beam joint and construction process

A technology of reinforced concrete beams and concrete columns, which is applied in the direction of architecture and building construction, and can solve the problems of multiple construction procedures, heavy workload, and long construction period, and achieve the effects of simple construction procedures, improved earthquake resistance, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

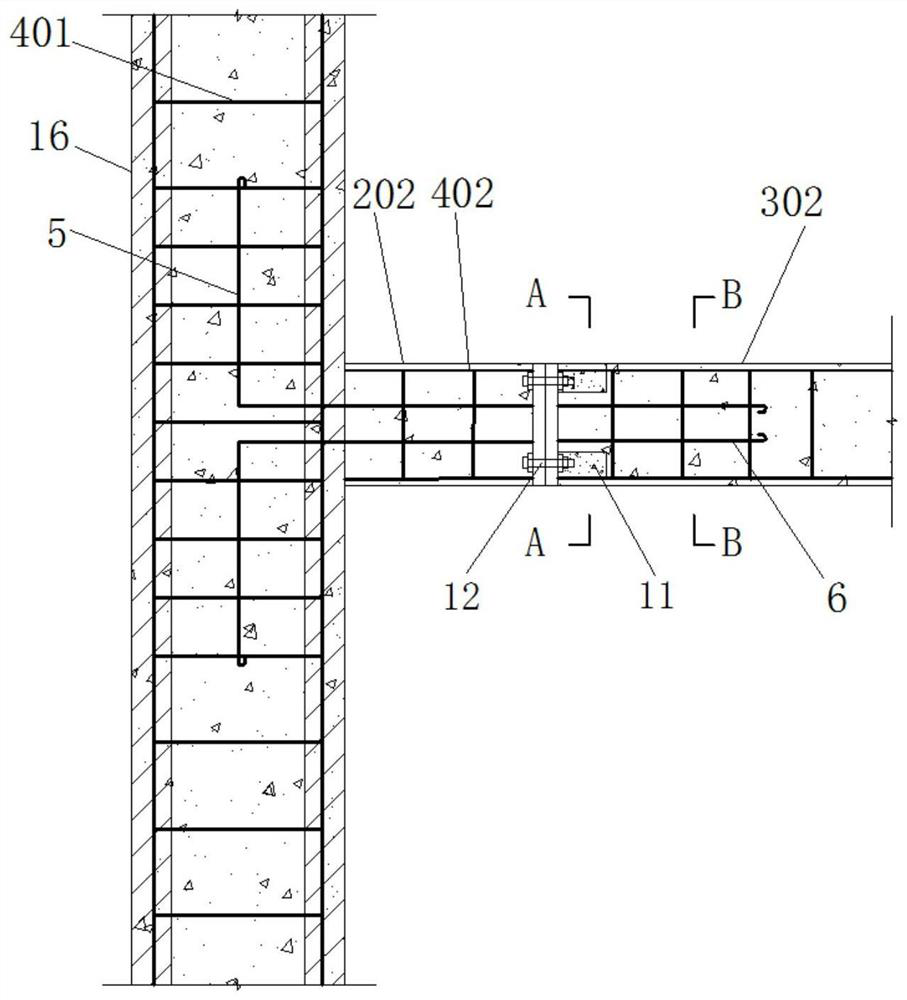

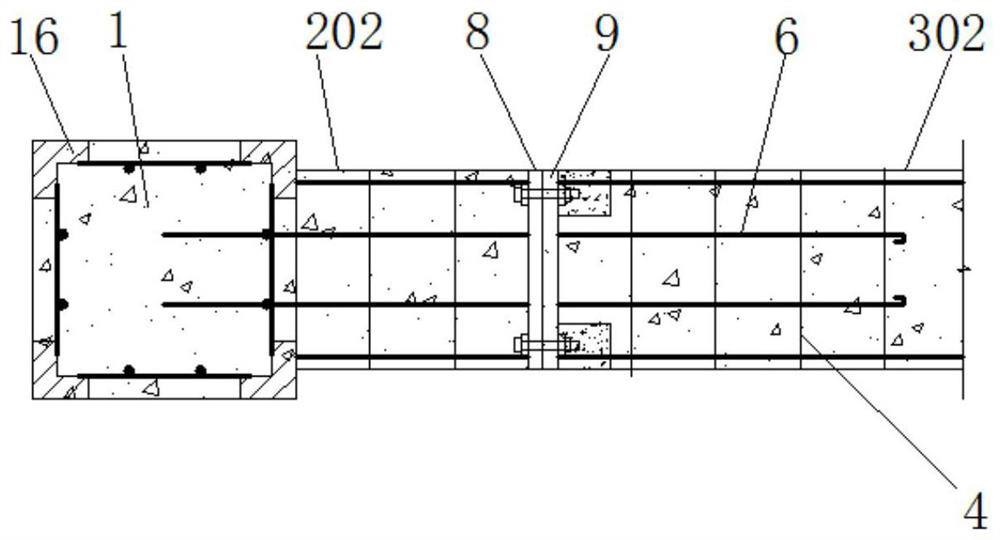

[0077] Such as Figure 1 to Figure 6As shown, the prefabricated outsourcing steel concrete column and the concrete beam joint include the prefabricated outsourcing steel concrete column 1, the prefabricated reinforced concrete beam 202 and the prefabricated reinforced concrete beam 302 embedded on the column; the prefabricated outsourcing steel concrete column 1 Including the steel skeleton 4 in the column, the outsourcing angle steel 16 and the anchoring steel bar 5 in the column, the outsourcing angle steel 16 is evenly distributed along the circumferential direction, and the steel skeleton 4 in the column is arranged at the geometric center of the area surrounded by the outsourcing angle steel 16, and the support of the outsourcing angle steel 16 The inner surface of the arm is welded to the end of the stirrup 401 of the steel skeleton 4 in the column, and the anchor steel bar 5 in the column is arranged inside the steel skeleton 4 in the column, and the two ends of the anch...

Embodiment 2

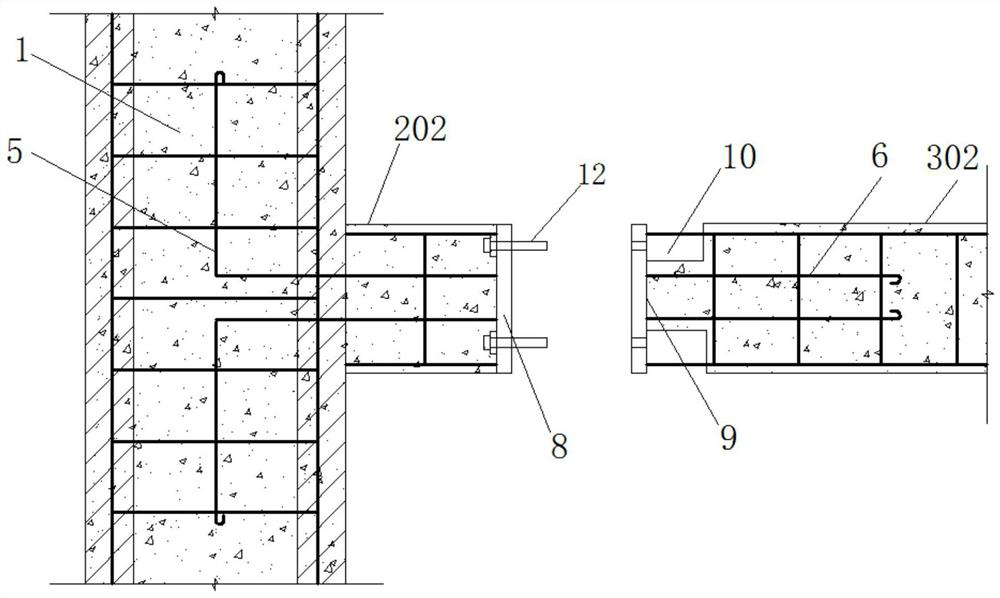

[0086] Such as Figure 7 to Figure 10 As shown, the difference between embodiment 2 and embodiment 1 is that the sections of the prefabricated reinforced concrete beam 202 and the prefabricated reinforced concrete beam 302 embedded on the column are both T-shaped, and the end plate I8 and the end plate II9 are both T-shaped end plate.

Embodiment 3

[0088] Such as Figure 11 to Figure 15 As shown, the difference between embodiment 3 and embodiment 1 is that the lower surfaces of the prefabricated reinforced concrete beams 202 and 302 prefabricated on the columns are respectively provided with outsourcing steel bottom plates 7, and one of the outsourcing steel The end of the base plate 7 is welded to the end plate I8, the end of the other outsourcing steel base plate 7 is welded to the end plate II9, and the upper surface of the outsourcing steel base plate 7 is welded to the stirrup 401 of the beam inner steel skeleton 4.

[0089] The construction technology of prefabricated steel-clad concrete columns and concrete beam joints includes the following steps:

[0090] Step 1, component making:

[0091] Manufacture a member composed of prefabricated steel-clad concrete column 1 and prefabricated reinforced concrete beam 202 pre-buried on the column, arrange the anchor steel bars 5 in the column according to the design, bind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com