Construction method of steel casing for ecological river foundation reinforcement

A foundation reinforcement and ecological river channel technology, applied in the direction of infrastructure engineering, soil protection, construction, etc., can solve the problems of increasing construction cost and construction period, adverse effects of hole verticality, and collapse at the hole of the enlarged pile, etc. Achieve the effect of improving the quality of construction, good reinforcement effect, and avoiding deformation and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

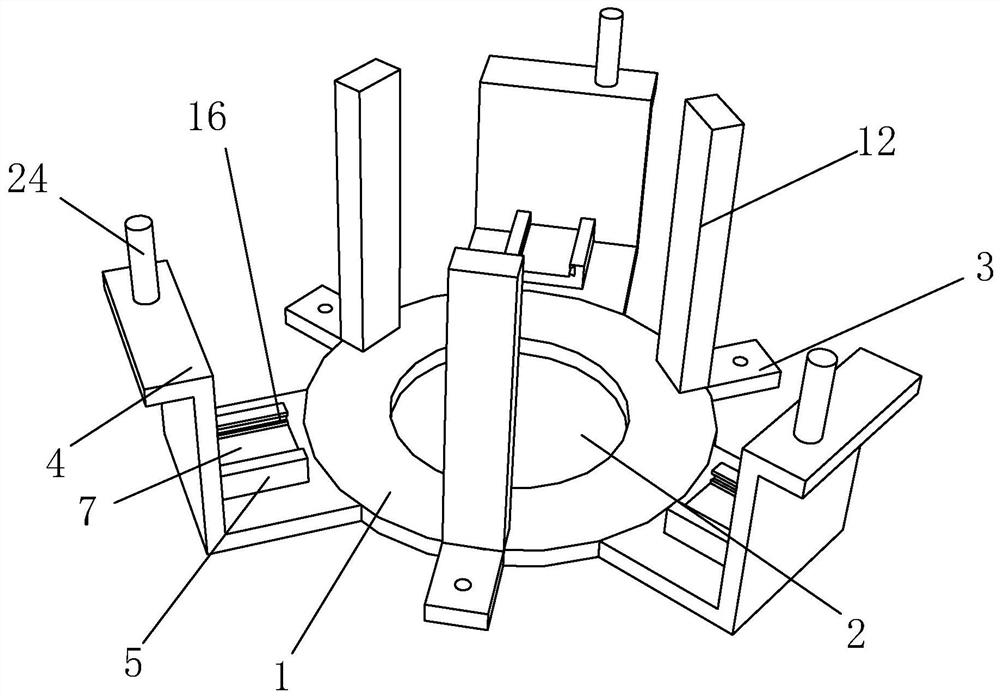

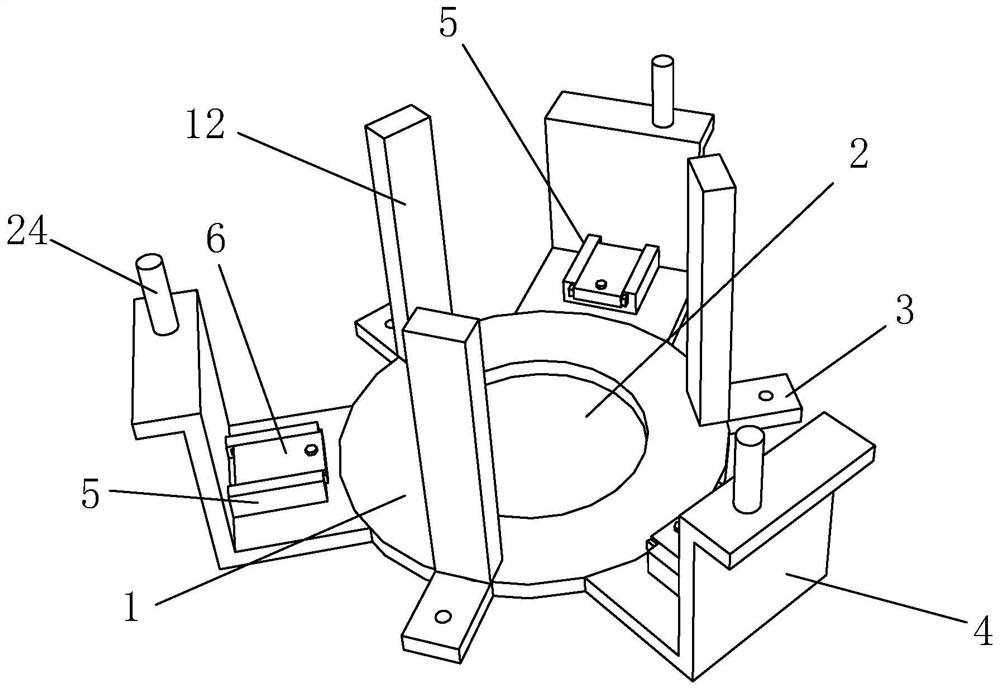

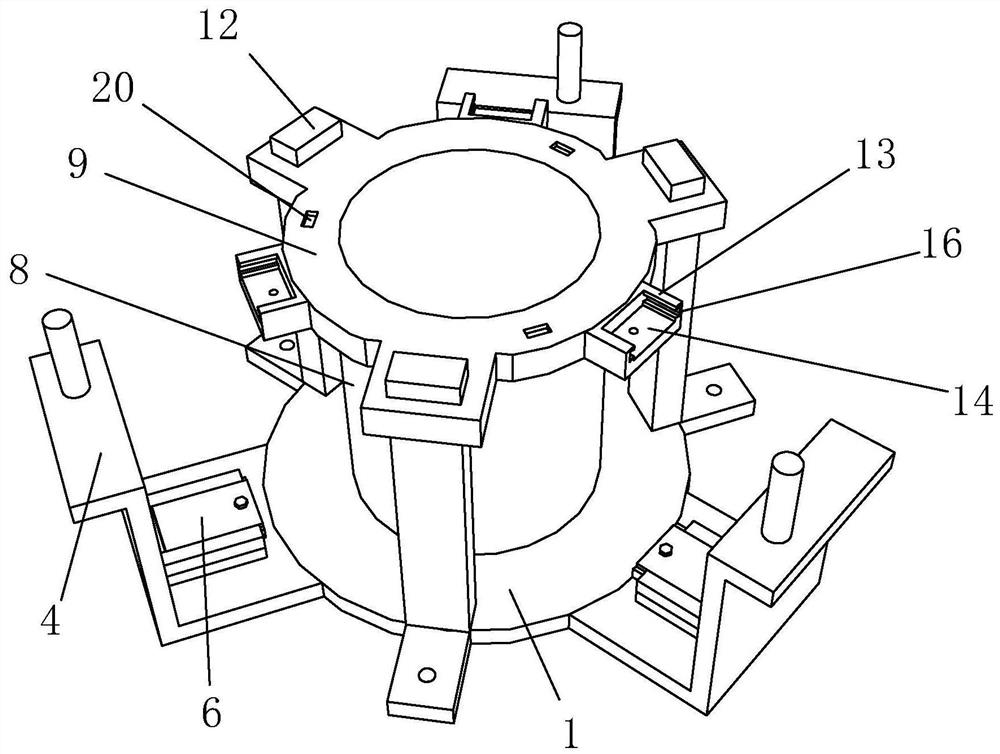

[0040] Such as Figure 1 to Figure 12 Shown, be the construction method of a kind of ecological river foundation reinforcement steel casing of the present invention, comprise the steps:

[0041] 1) Construction preparation;

[0042] 2) Installation of positioning base 1:

[0043] (1) Install the positioning base 1 to the pile position, ensure that the pile position is completely located in the positioning hole in the center of the positioning base 1, and then adjust the position of the positioning base 1 so that the center of the positioning hole 2 coincides with the pile position, and the positioning The outer wall of the base 1 is provided with a positioning plate 3. After the position of the positioning base 1 is adjusted, the positioning base 1 and the ground are installed and fixed through the holes reserved on the positioning plate 3 and the ground screws; Position the position of the base 1 so that the center of the positioning hole 2 of the positioning base 1 is cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com