Curved-surface earthenware brick curtain wall

A ceramic brick and curved surface technology, applied in the field of curved ceramic brick curtain wall, can solve the problems of technical difficulty, construction difficulty, heavy weight, etc., and achieve the effect of enhanced connection strength and simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

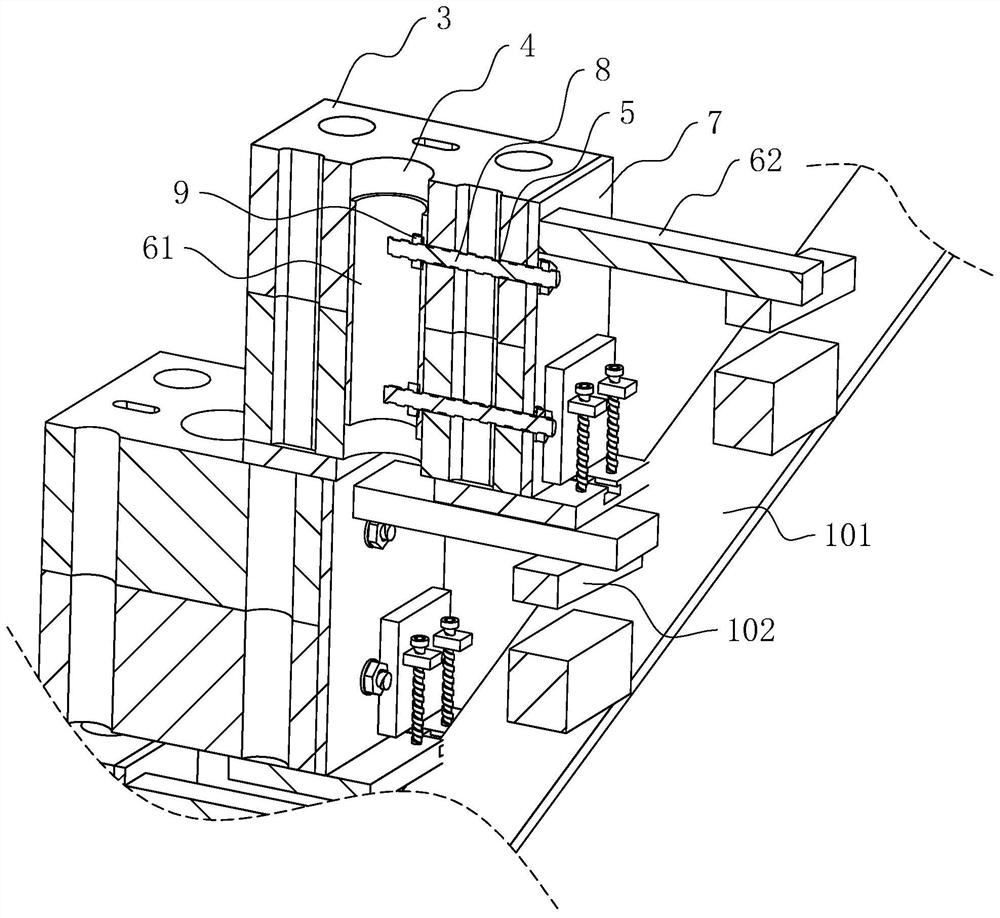

[0034] The following is attached Figure 1-6 The application is described in further detail.

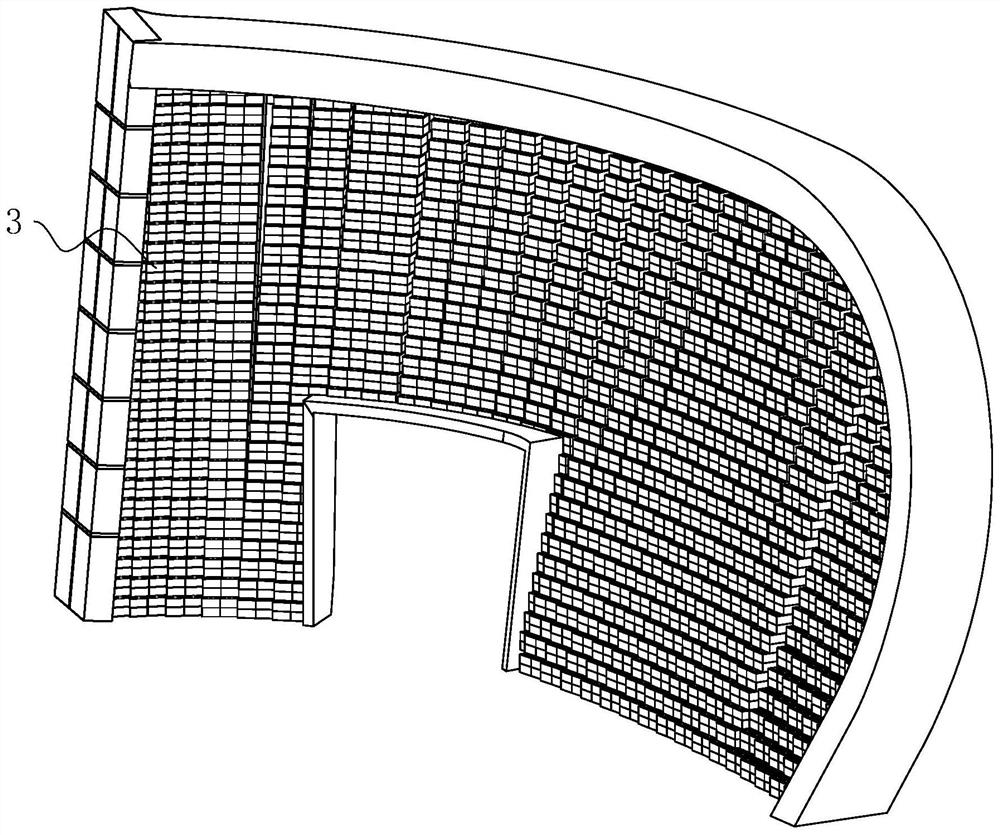

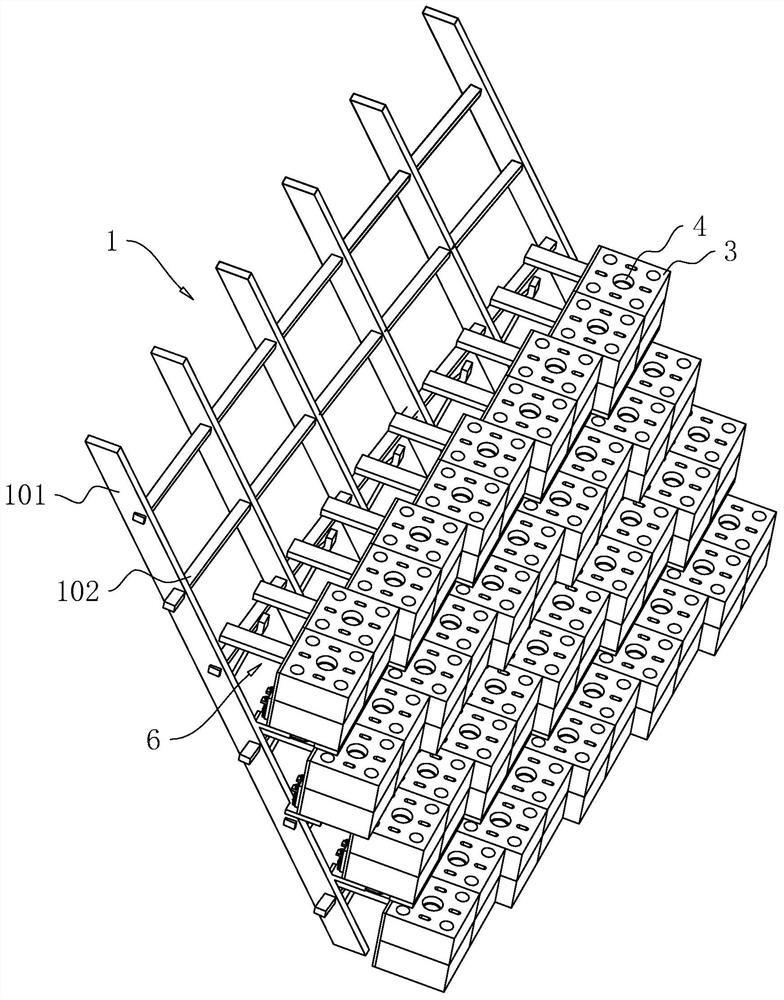

[0035] The embodiment of the present application discloses a curved ceramic brick curtain wall. refer to figure 1 and figure 2 , the ceramic brick curtain wall includes a mounting bracket 1 for matching the shape of the curved wall. Multiple groups of ceramic brick groups are fixed on the mounting bracket 1. Multiple groups of ceramic brick groups form an arc-shaped step layer on the same horizontal plane. The top is stacked step by step, and the groups of clay bricks in adjacent step layers are arranged in a staggered manner, and the groups of ceramic bricks in the same step layer are also arranged in a staggered manner. A reinforcement layer for connecting with the ground is provided at the lower end of the lowest step layer, and the reinforcement layer can be formed by pouring concrete.

[0036] refer to figure 2 , the installation bracket 1 includes a plurality of oblique ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com