Flexible expansion control method and system for cut-out wind speed of megawatt wind turbine generator

A technology for wind turbines and cut-out wind speed, which is applied in the control of wind turbines, engine control parameters, wind power generation, etc. It can solve the problems of loss of "gale" capture ability, increase of fatigue and ultimate load, and influence on unit safety, etc., to achieve Full exploitation of performance potential, less batch trawl, less cut-out and re-cut-in process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

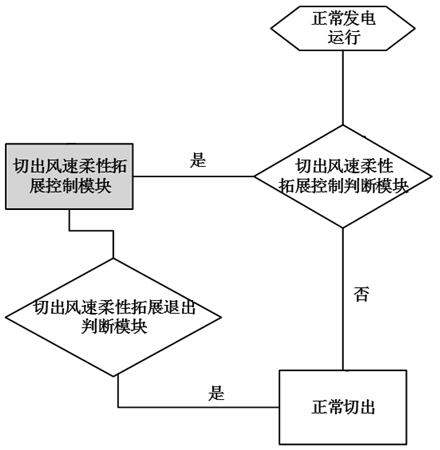

[0023] Combine below figure 1 Embodiments of the present invention are described in detail.

[0024] The flexible extended control method for cut-out wind speed of a megawatt wind turbine is characterized in that it includes the following steps:

[0025] Step 1: Obtain the preset load matrix composed of multiple load elements in the wind turbine application site;

[0026] Step 2: Compare and analyze the real-time load of the wind turbine with the preset load matrix to determine whether to perform flexible expansion control of cut-out wind speed, if so, proceed to the next step, otherwise, perform normal cut-out wind speed control;

[0027] The third step: by adjusting the power characteristics of the wind turbine, the flexible expansion control of the cut-out wind speed is carried out;

[0028] Step 4: When the cut-out wind speed flexible extended control runs to the set time or a load element in the wind turbine application site exceeds the range of the preset load matrix, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com