A high damping fluid damper

A fluid damper and high damping technology, applied in the field of vibration reduction, can solve problems such as poor low frequency vibration isolation performance, and achieve the effects of high static bearing capacity, stable vibration isolation effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

[0029] The present invention provides a high damping fluid damper.

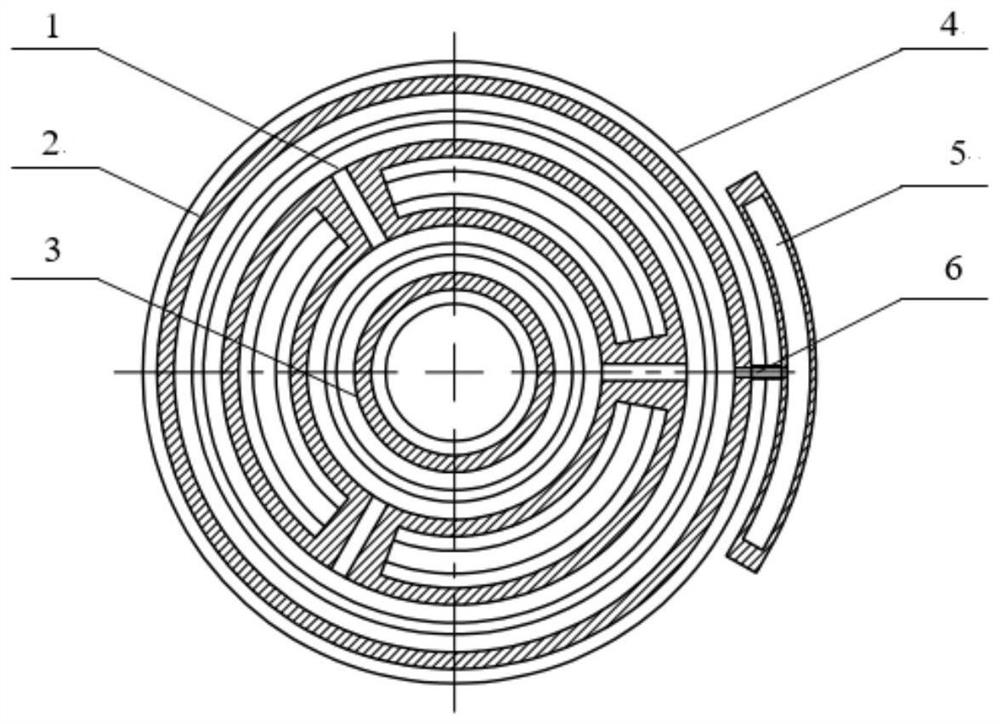

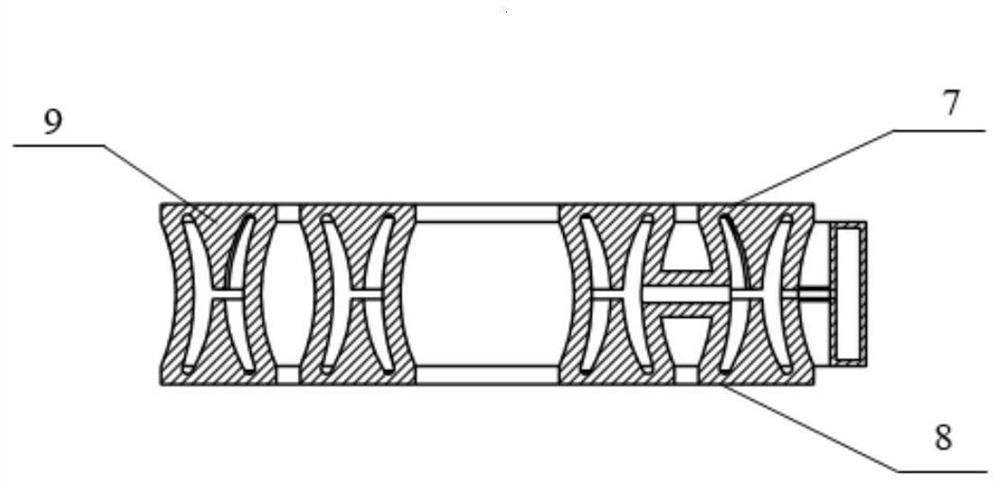

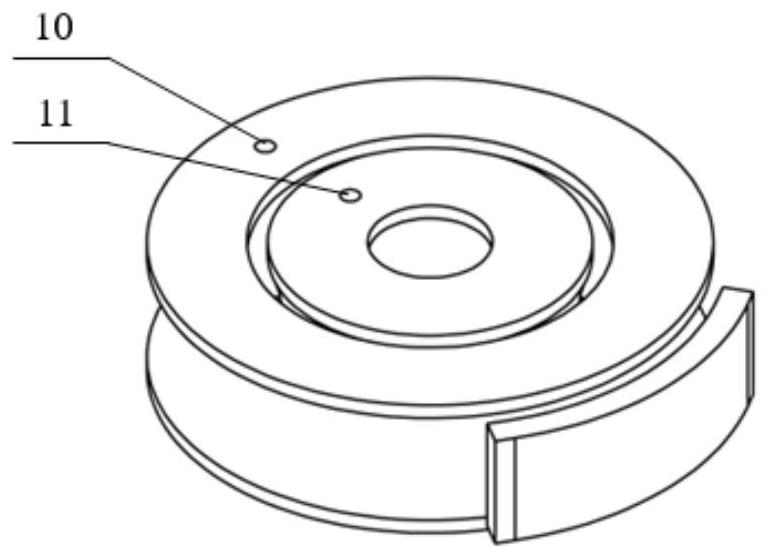

[0030] like Figure 1-Figure 5 As shown, an annular high-damping fluid damper includes an annular high-damping structural member 18, a viscous fluid and an upper high-rigidity panel 19 and a lower high-rigidity panel 20. The annular high-damping structural member 18 is located on the upper high-rigidity panel 19 and the lower high-rigidity panel 19. Between the panels 20, the upper high-rigidity panel 19 and the lower high-rigidity panel 20 are respectively connected to two objects that need to isolate and transmit vibrations to each other through the connecting studs 17; , the annular buffer cavity 5 is connected with the annular damping disc 4 through the buffer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com