Chopping feeding transmission and application of chopping machine thereof

A transmission and guillotine cutting technology, which is applied in the direction of mechanical equipment, gear transmission devices, and components with teeth, etc., can solve the problems of low efficiency of variable speed operation, limited application range, and wrong gear position, so as to ensure the safety of operation and avoid The effect of the card machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

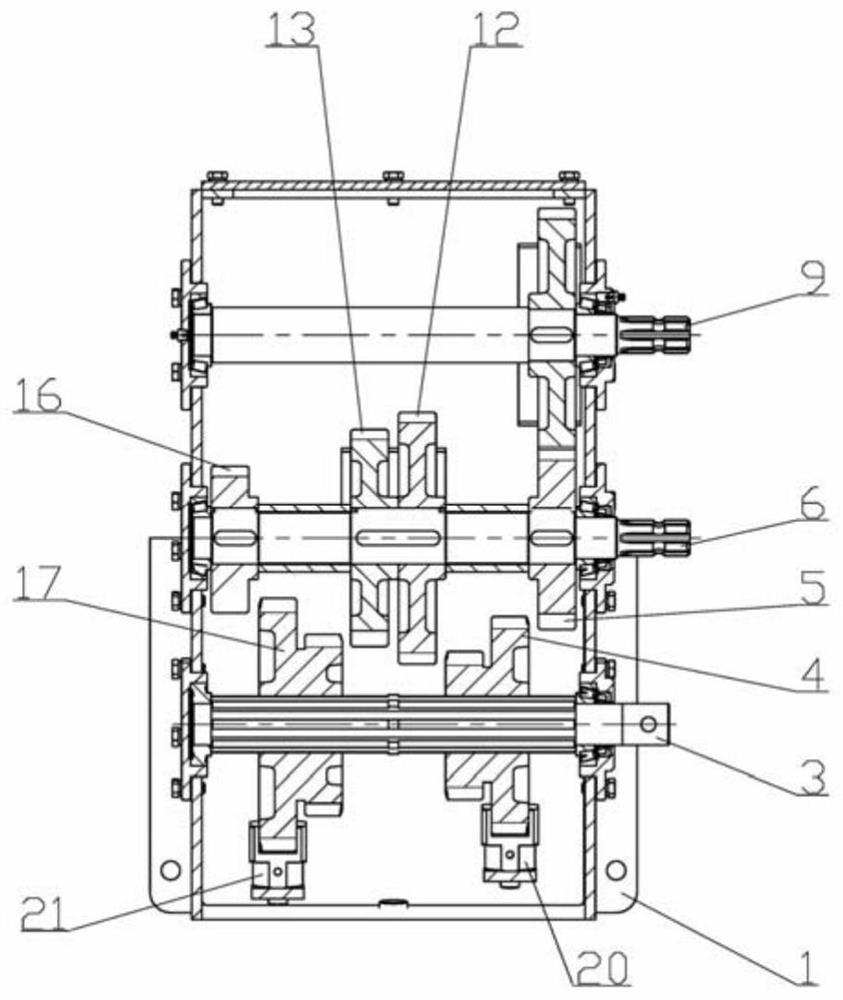

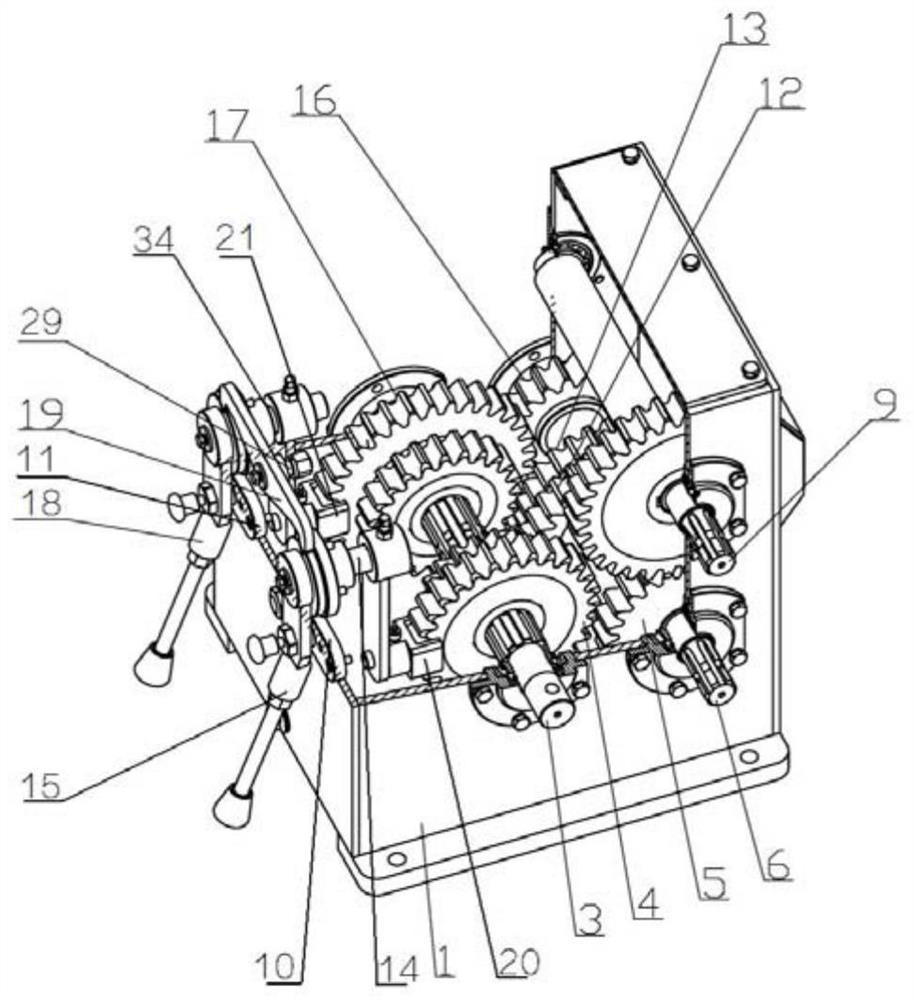

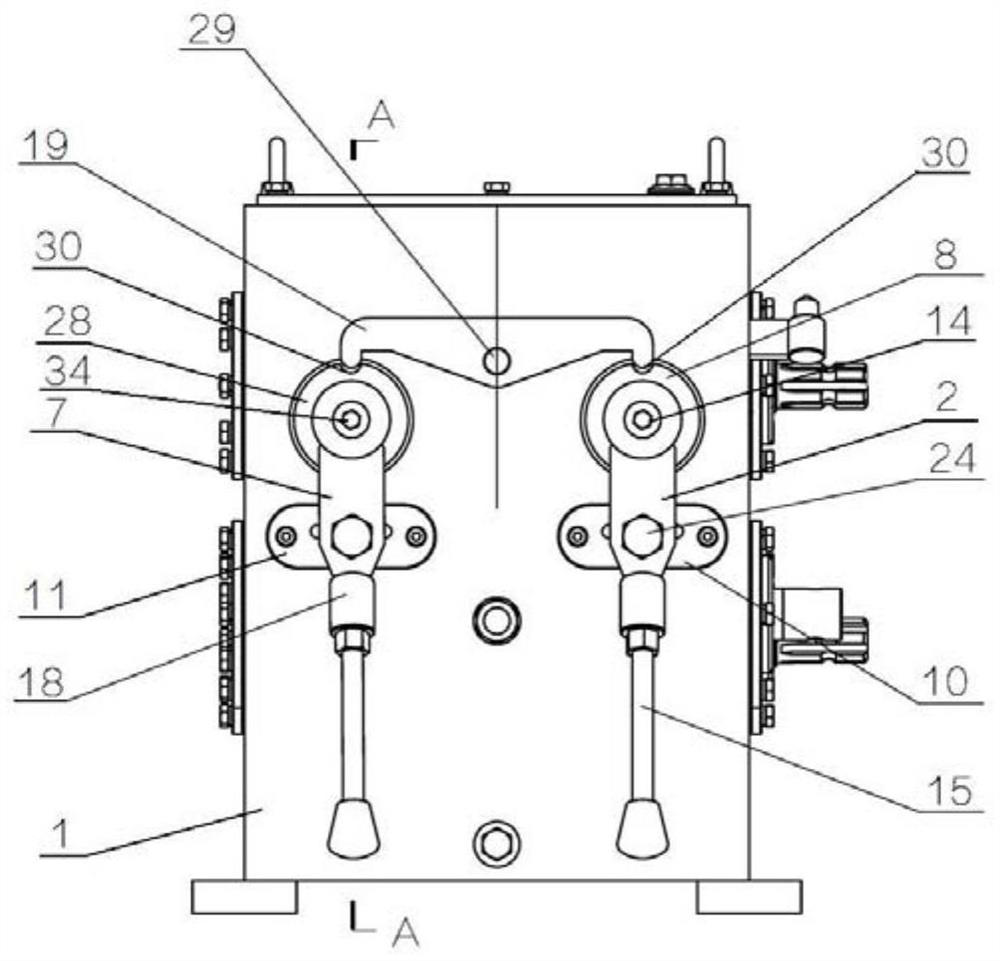

[0014] Such as figure 1 As shown, the guillotine cutting feed transmission of this patent application includes a gearbox 1, a shaft 3 assembled in parallel in the gearbox 1, a second shaft 6, and a reverse shaft 9, and also includes a shift fork, and the second shaft 6 is a shaft 3 and the intermediate shaft between the countershaft 9 is connected with the countershaft 9 fixed teeth meshing transmission.

[0015] In the first shaft 3, the sliding key on the shaft is provided with two groups of gears 4 and 17, and on the second shaft 6, corresponding to each group of gears 4 and 17 in the left and right stroke shift positions, there is a pair of meshing components. The rotational speed pairs of gears of each shifting gear include the middle and small teeth 5 that mesh with the first gear double gear 4 right-stroke shift position to form a medium and low gear speed, and the left-stroke shift position that meshes with a large tooth 12 that forms a medium and high-grade speed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com