Adjustable constant force output mechanism with curved cam

A constant force output, curved cam technology, applied in cams, mechanical equipment, control/adjustment systems, etc., can solve the problems of inability to output adjustable constant force, difficult to apply to practical engineering projects, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

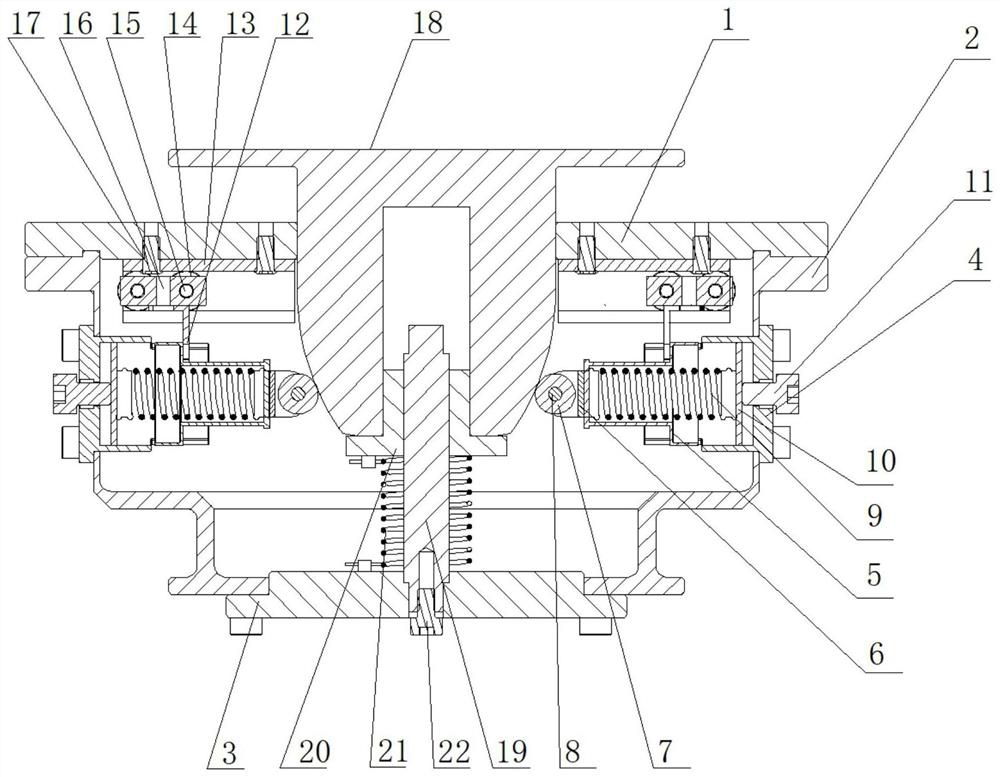

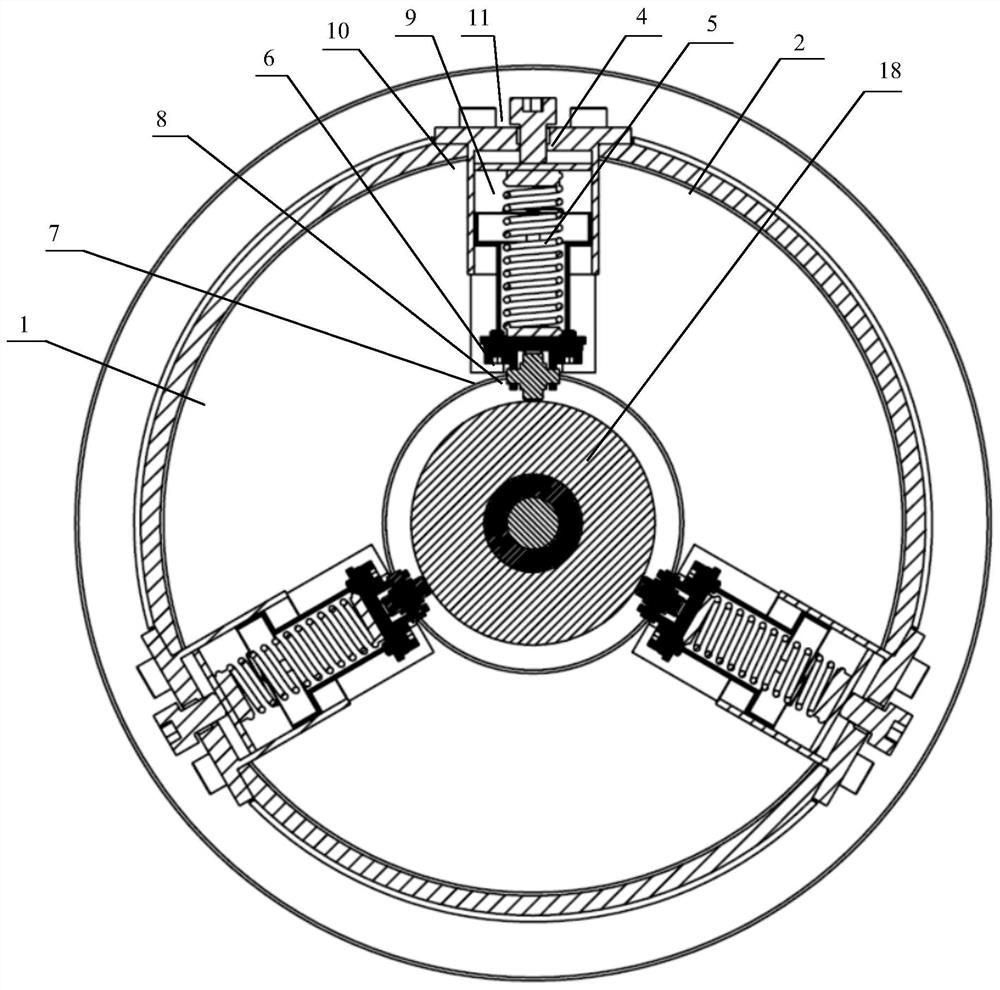

[0027] In conjunction with the accompanying drawings, the present invention will be described in further detail.

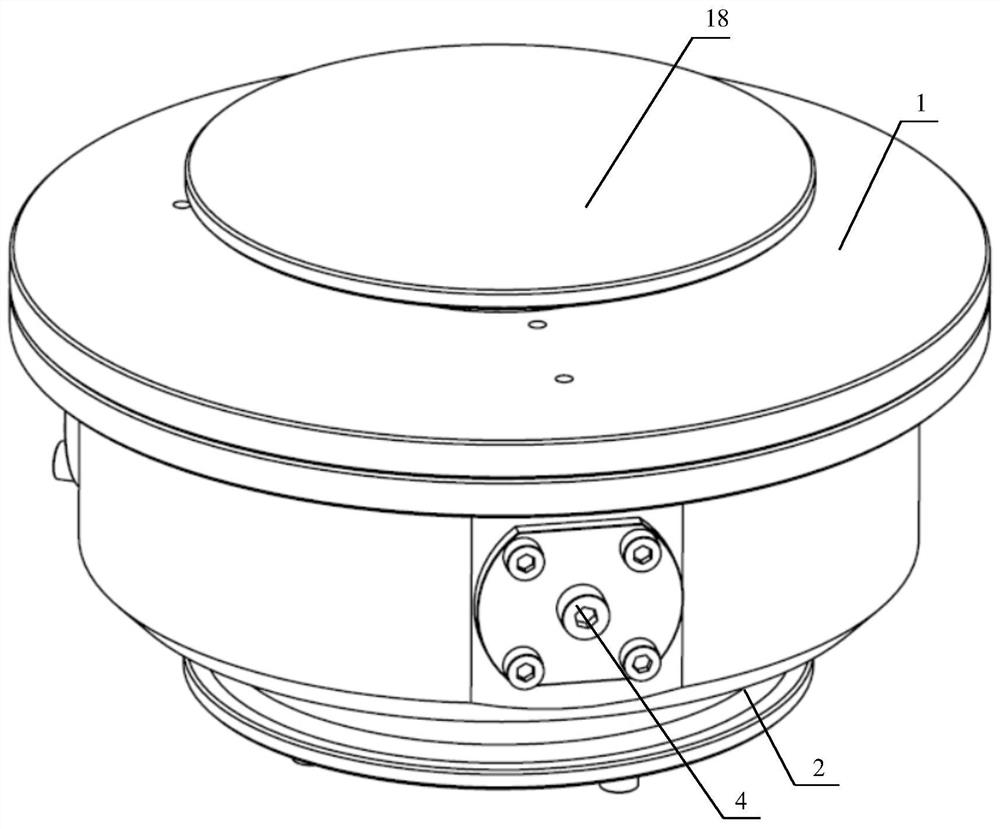

[0028] In this embodiment, the structure of a curved surface cam adjustable constant force mechanism is as follows figure 1 , 2 As shown, it consists of a base component, a horizontal adjustment component, a horizontal restraint component, an output force component, and a vertical auxiliary adjustment component;

[0029] The base assembly is composed of a top cover (1), a body sleeve (2), and a flange cover (3); the top cover (1), the body sleeve (2), and the flange cover (3) are sequentially connected;

[0030] Such as Figure 4 , the horizontal adjustment assembly consists of an outer sleeve (4), an inner sleeve (5), a roller mounting frame (6), a roller (7), a pin shaft (8), a spring (9), a bottom plate (10), an adjustment The screw (11) is composed of; the outer sleeve (4) and the body sleeve (2) are connected by threads; the outer sleeve (4) and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com