A two-dimensional thermal acoustic vector sensor chip and its implementation method

An acoustic vector sensor and chip technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as large self-noise, poor high-frequency characteristics, and inability to guarantee the flow field at the same time, and achieve the effect of eliminating distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment adopts a bracket type, each group of support frames includes a support frame, and the form of the support frame adopts an inner penetrating hollow structure surrounded by four frames; the thermal acoustic vector sensor adopts a three-wire thermal acoustic vector sensor.

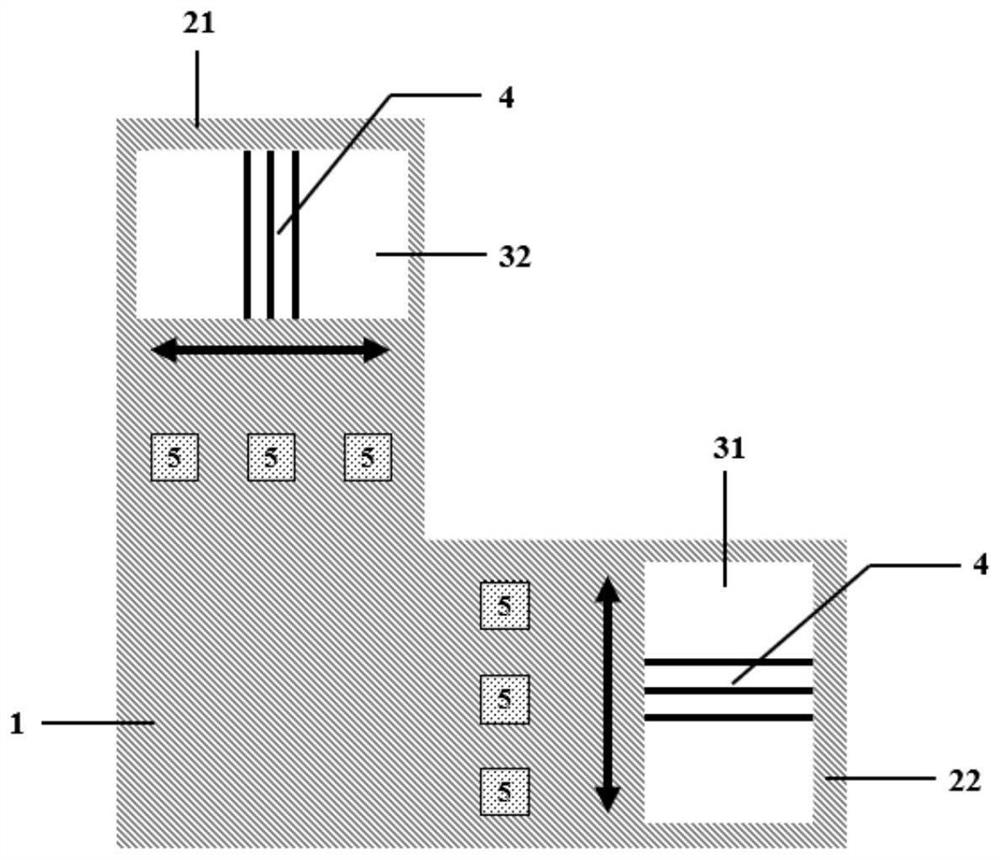

[0054] like figure 1 As shown, the two-dimensional thermal acoustic vector sensor chip of this embodiment includes: a substrate 1, a vertical support frame 21, a horizontal support frame 22, a horizontal flow channel 32, a vertical flow channel 31, a thermal acoustic vector sensor 4 and Electrode 5; wherein, two sets of mutually perpendicular support frames are arranged on the edge of the substrate 1, and the two sets include a support frame, and the two support frames are perpendicular to each other, respectively, a vertical support frame 21 and a horizontal support frame 22, and the vertical support frame 21 and the horizontal support frame 22 are both hollow internally, and the shape...

Embodiment 2

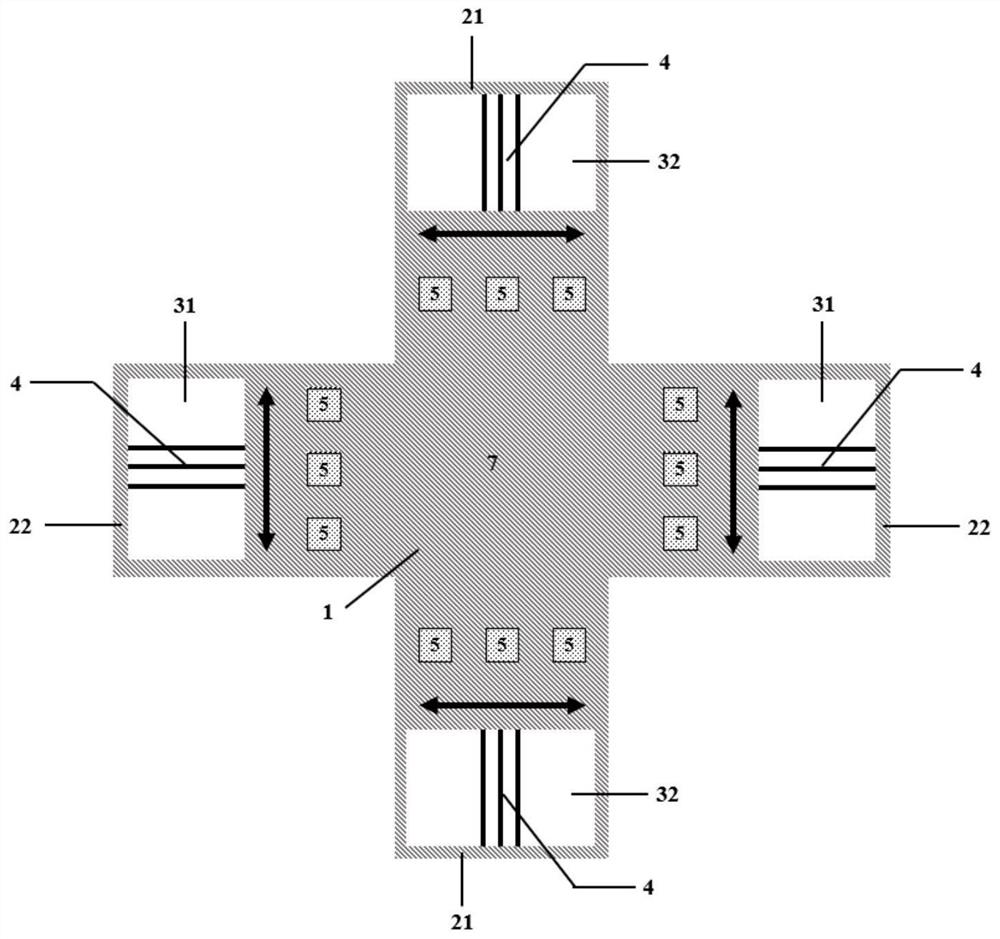

[0056] This embodiment of the present embodiment adopts a bracket type, each group of support frames includes two support frames, and the central axes of the two support frames in each group are located on the same straight line, so that two single shafts are integrated in the direction of one flow channel The thermal acoustic vector sensor ensures that the acoustic centers 7 of the two sensitive axes are at the same point, and the others are the same as the first embodiment.

Embodiment 3

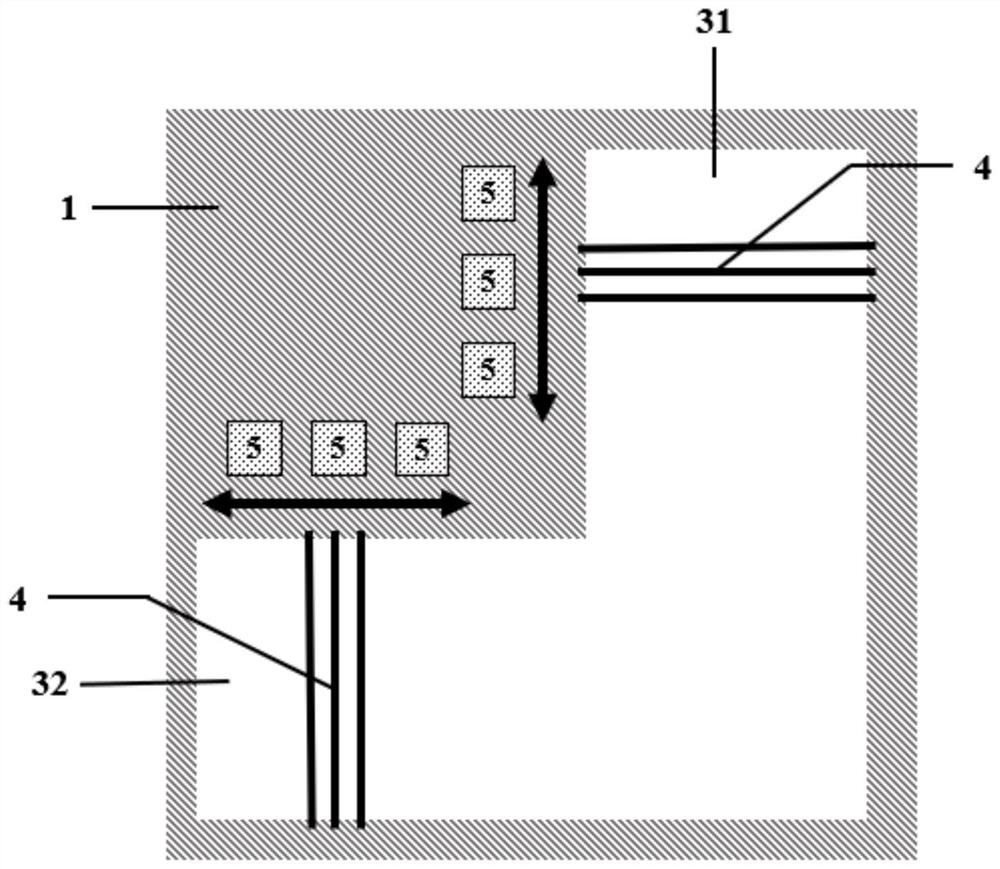

[0058] This embodiment adopts a hollow type, each group of vertical flow channels 31 includes a vertical flow channel 31, and each group of horizontal flow channels 32 includes a horizontal flow channel 32; the hollow type form is formed by penetrating the center of the substrate 1 to form The interior is hollow and has an edged form.

[0059] like image 3 As shown, the two-dimensional thermal acoustic vector sensor 4 chip in this embodiment includes: a substrate 1, a horizontal flow channel 32, a vertical flow channel 31, a thermal acoustic vector sensor 4 and electrodes; Hollowing treatment is performed to form two sets of vertical flow channels 31 and horizontal flow channels 32 that are perpendicular to each other, each group includes a vertical flow channel 31 or a horizontal flow channel 32, and the vertical flow channel 31, that is, the direction of the flow channel is vertical The direction of the horizontal flow channel 32, that is, the direction of the flow channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com