Method for detecting defects of grouting material structure between fabricated pier and bearing platform

A technology for structural defects and detection methods, applied in the direction of analyzing materials, processing detection response signals, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

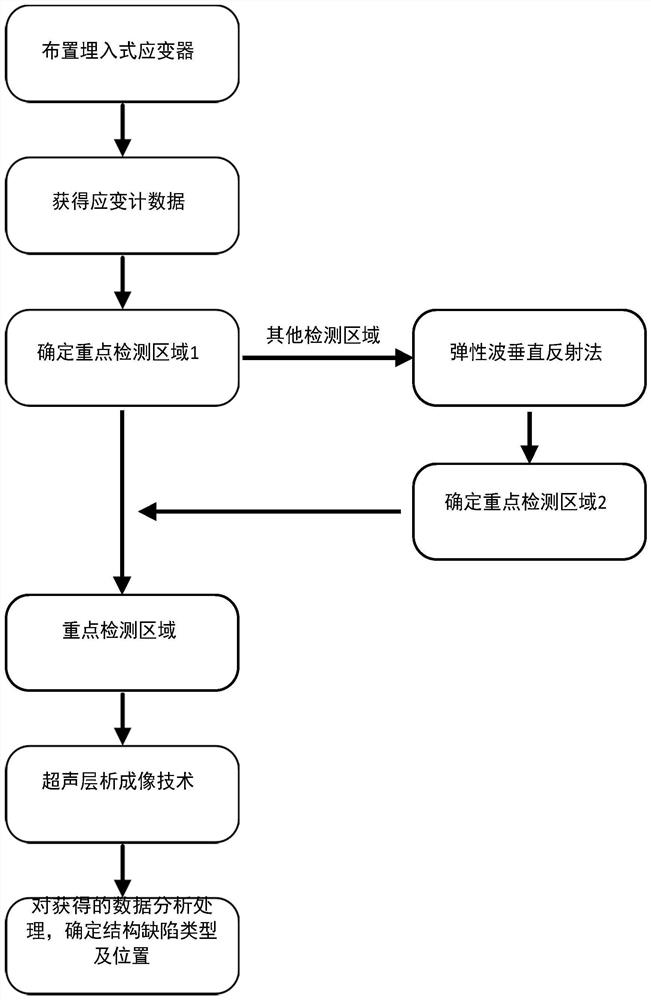

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

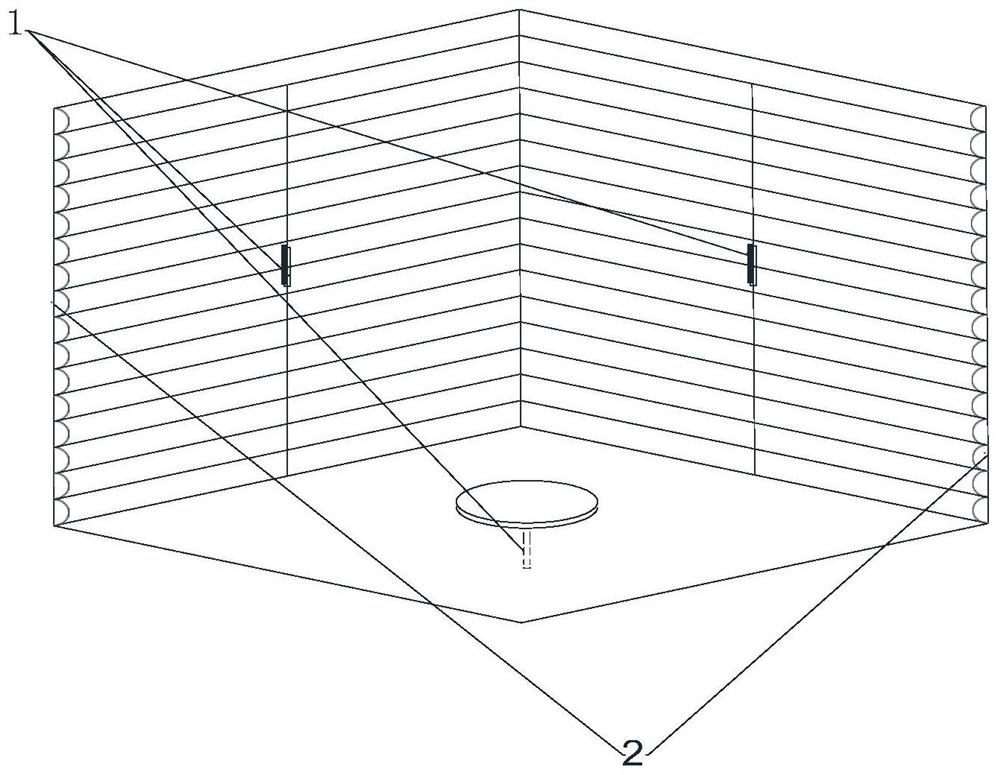

[0047] Such as figure 2 As shown, the specific methods of strain gage layout include,

[0048] 1) Before the lifting of the pier is completed, drill a round hole with a diameter of 3cm and a depth of 15cm at the bottom of the cap groove, put the strain gauge in, seal it with the mortar corresponding to the cap, and then start recording the data of the strain gauge;

[0049] 2) After the hoisting of the pier is completed, the strain gauge is tied to the middle of the steel bar with a diameter of 10mm consistent with the depth of the cap, and placed vertically into the four gaps between the cap and the side of the pier, and then poured in grouting material to record the data of the strain gauge;

[0050]3) Then analyze the strain gauge data, and compare the strain value generated by the self-weight of the pier with the strain gauge reading according to the specific theoretical calculation, and determine the key detection area if the value is greatly different from the theoretic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com