Rubber insulated wire skin breaking and coring device

A technology of coring device and rubber insulation, which is applied to equipment for dismantling/armoring cables, recycling technology, electrical components, etc. Simple structure, improve peeling efficiency, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

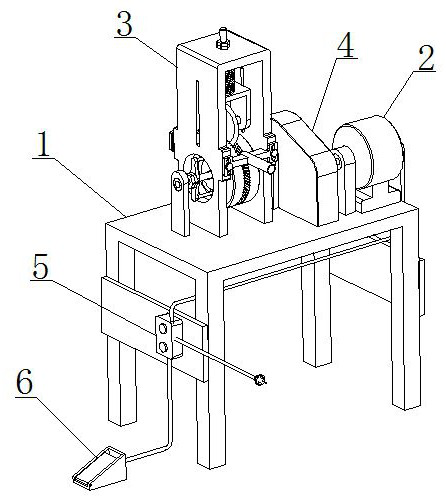

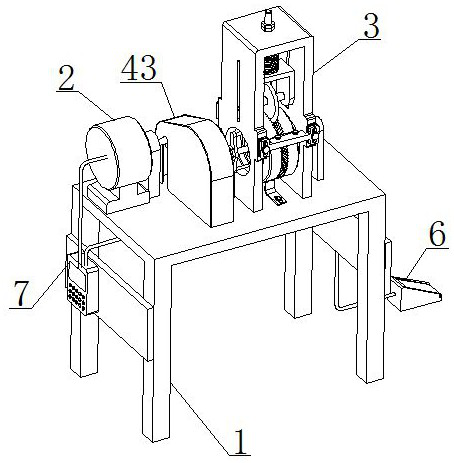

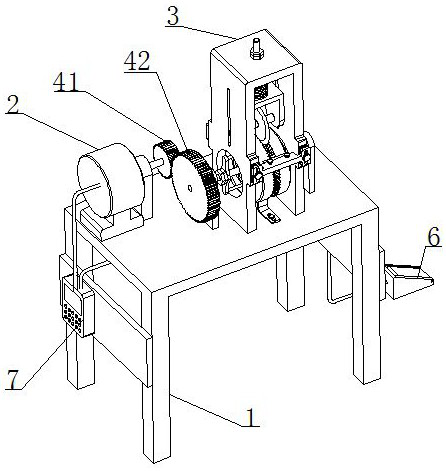

[0030] see Figure 1 to Figure 12 As shown, a rubber insulated wire breaking and coring device includes a bracket 1, a servo motor 2, a peeling device 3, a deceleration device 4, a control switch 5, a foot switch 6 and a frequency converter 7, and the peeling device 3 is arranged on the bracket 1 Above, the servo motor 2 is connected to the peeling device 3 through the deceleration device 4, the servo motor 2 drives the peeling device 3 through the deceleration device 4, the servo motor 2 is connected to the frequency converter 7 through the wire, and the frequency converter 7 is connected to the control switch 5 through the wire , the control switch 5 is communicated with the external power supply, and the foot switch 6 is connected with the control switch 5 through a wire;

[0031] Specifically, the worker adjusts the motor speed by adjusting the frequency converter, controls the rotation and stop of the servo motor 2 through the foot switch 6, and controls the power on and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com