High-strength steel plate having excellent formability, toughness and weldability, and production method of same

A high-strength steel plate and manufacturing method technology, applied in the direction of manufacturing tools, metal rolling, furnaces, etc., can solve the problems of reduced formability and difficulty in processing, and achieve the effect of excellent toughness and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0543] (Example 1: Manufacture of steel plate for heat treatment)

[0544] Molten steels having the composition shown in Table 1 and Table 2 were cast to produce steel slabs. Next, the billets were hot-rolled under the conditions shown in Tables 3 to 4.

[0545] Table 1

[0546]

[0547] ※Underlined items are outside the scope of the present invention.

[0548] Table 2

[0549]

[0550] ※Underlined items are outside the scope of the present invention.

[0551] table 3

[0552]

[0553] ※Underlined items are outside the scope of the present invention.

[0554] Table 4

[0555]

[0556] ※Underlined items are outside the scope of the present invention.

[0557] The hot-rolled steel sheets were further processed under the conditions shown in Tables 5 to 9 to obtain heat-treated steel sheets.

[0558] The examples described as "manufacturing method A" in Tables 5 to 9 are examples manufactured by the manufacturing method a1 (without performing intermediate heat ...

Embodiment 2

[0571] (Example 2: Manufacture of high-strength steel plate)

[0572] By subjecting the steel sheets for heat treatment shown in Tables 10 to 14 to heat treatment (final heat treatment) under the conditions shown in Tables 15 to 20, high-strength steel sheets excellent in formability, toughness, and weldability can be obtained.

[0573]

[0574]

[0575]

[0576]

[0577]

[0578]

[0579] Some steel sheets for heat treatment were subjected to plating treatment under the conditions shown in Table 21 in addition to the heat treatments shown in Tables 15 to 20. It should be noted that in Table 21, GA refers to an alloyed hot-dip galvanized steel sheet, GI refers to a non-alloyed hot-dip galvanized steel sheet, and EG refers to an electroplated steel sheet.

[0580] Table 21

[0581]

[0582] ※Underlined items are outside the scope of the present invention.

[0583] Tables 22 to 27 show the microstructures of the obtained high-strength steel sheets and the ...

experiment example 2

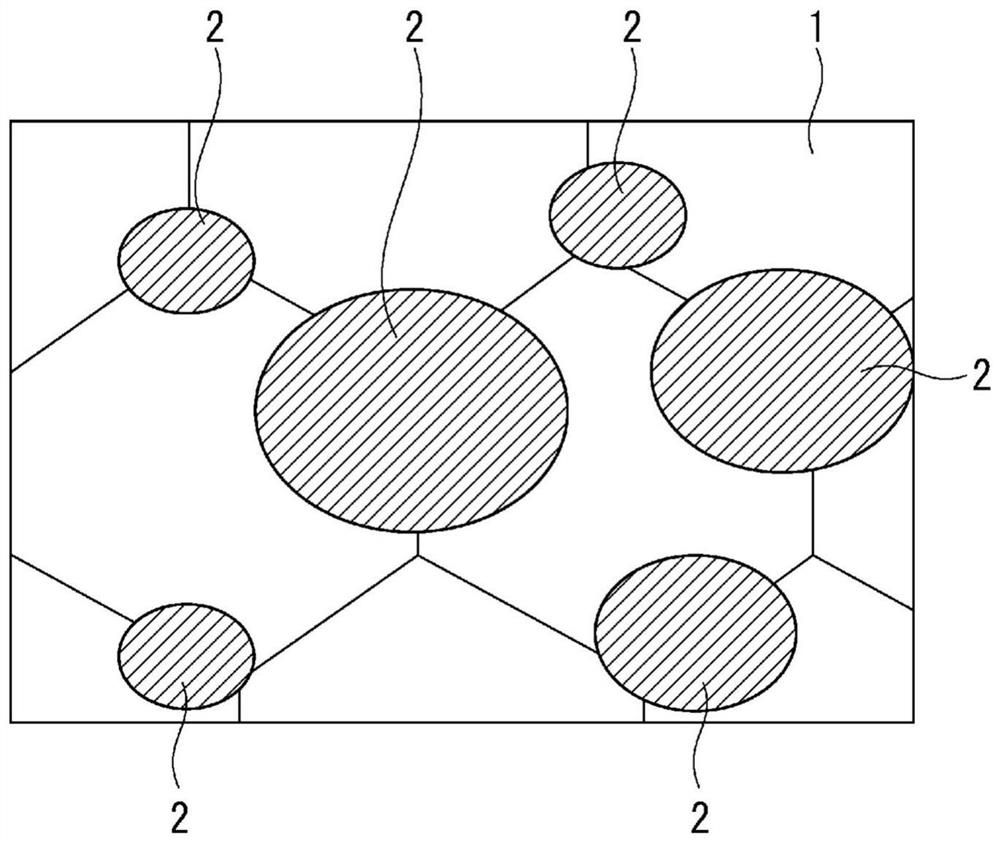

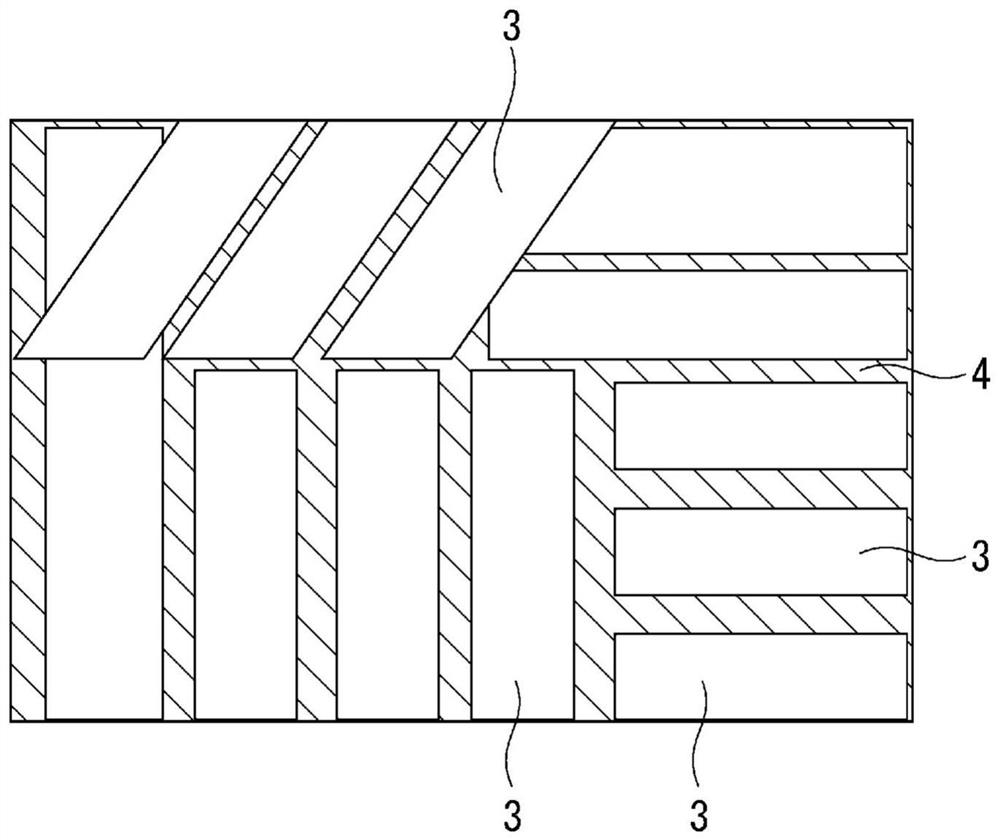

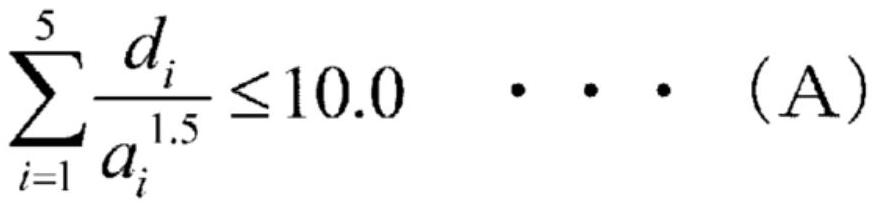

[0609] Experimental example 2 is an example in which the temperature change process during the heating process does not satisfy the formula (3) when the steel plate 1a for heat treatment is heat treated, and the steel plate that has a large amount of coarse and massive martensite and does not satisfy the formula (A) has a toughness become inferior.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com