Cleaning device for inner wall of chimney of thermal power plant

A technology for cleaning devices and thermal power plants, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems of dust affecting air quality, reducing the service life of chimneys, and damage to anti-corrosion materials. Necessary loss, simple and quick use process, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings.

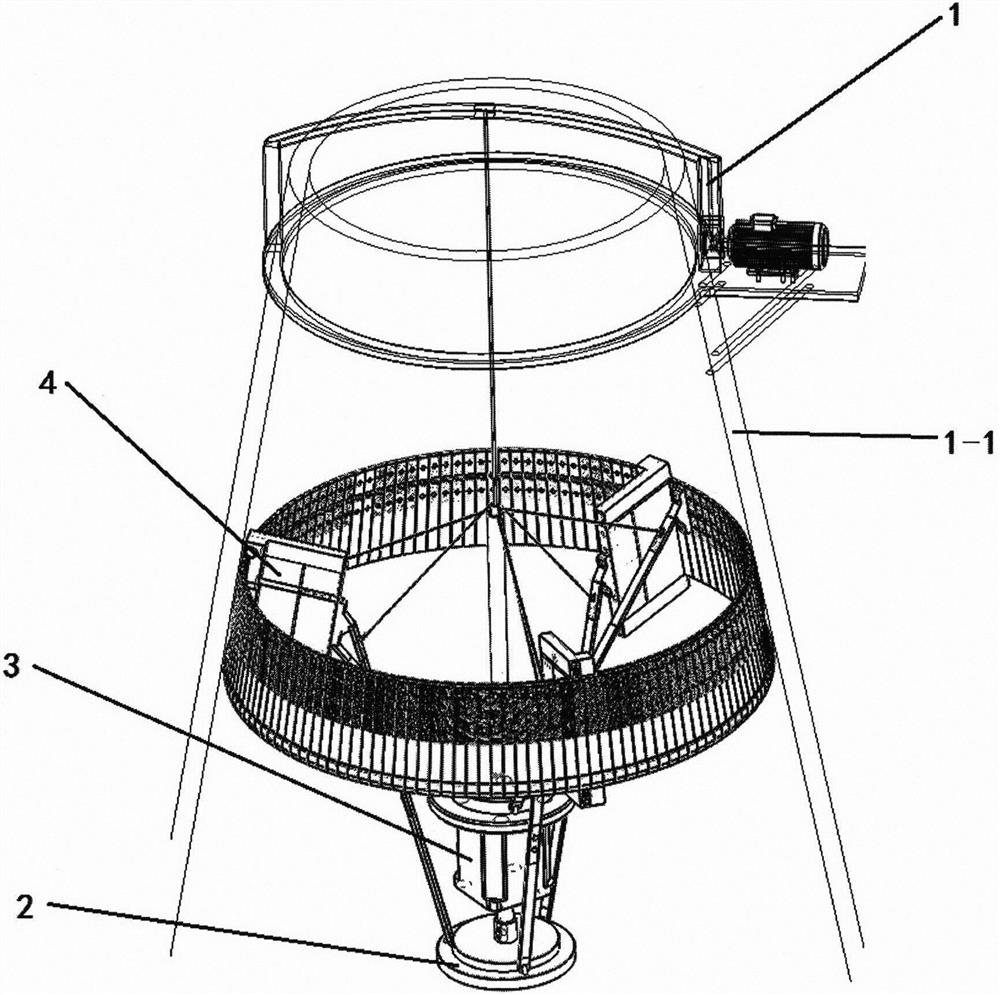

[0027] A device for cleaning the inner wall of a thermal power plant chimney, such as figure 1 As shown, it includes a fixed lifting module 1, a driving module 2, a supporting structure module 3, a cleaning module 4 and a chimney 1-1. The fixed lifting module 1 is located at the uppermost end of the device to ensure the stability of the device; the driving module 2 is installed around the support structure module 3; The core part, all components are supported on the support structure module 3; the cleaning module 4 is located around the support structure module 3.

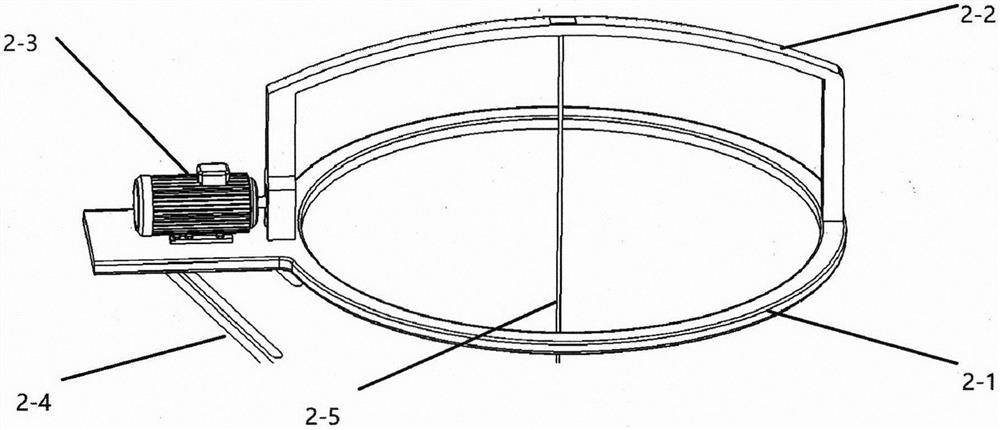

[0028] Such as figure 2 As shown, the fixed lifting module includes an annular fixing device 2-1, a lateral support rod 2-2, a lifting motor 2-3, a fixed rod 2-4, and a lifting rope 2-5. The annular fixing device 2-1 is installed on the top of the chimney of the thermal p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap